Drying method of fresh tremella fuciformis

A drying method and technology of fresh white fungus, which is applied in the field of food processing, can solve the problems of poor drying effect of fresh white fungus, affecting appearance and quality, and achieve the effect of retaining taste and nutrition, maintaining appearance and color, and avoiding uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

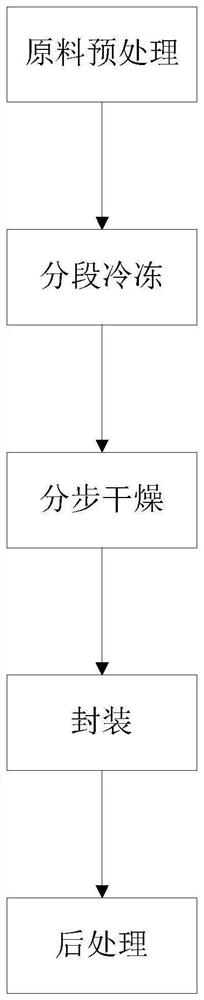

[0030] The present invention preferably a kind of drying method of fresh white fungus, comprises the following steps:

[0031] Step 1: raw material pretreatment; select 1 kg of whole fresh white fungus raw material, wherein the fresh white fungus has a water content of 80%, wash the fresh white fungus raw material with water to remove surface impurities, drain and obtain fresh white fungus a, and set aside;

[0032] Step 2: Sectional freezing; put the fresh white fungus a in step 1 on a flat plate, put it into an ultra-low temperature refrigerator for the first stage of pre-freezing, control the temperature in the ultra-low temperature refrigerator to -75°C, and then place the empty box of the freeze-drying box The temperature is lowered to -60°C at a rate of 10°C / min, and the fresh white fungus a that has been frozen after the first stage of pre-freezing is quickly placed on the material rack in the pre-cooled vacuum freeze dryer cavity, and the second step is carried out. Af...

Embodiment 2

[0037] A drying method for fresh white fungus, comprising the following steps:

[0038] Step 1: raw material pretreatment; select 1 kg of whole fresh white fungus raw material, wherein the fresh white fungus has a water content of 75%, wash the fresh white fungus raw material with water to remove surface impurities, drain and obtain fresh white fungus a, and set aside;

[0039] Step 2: Sectional freezing; put the fresh white fungus a in step 1 on a flat plate, put it in an ultra-low temperature refrigerator for the first stage of pre-freezing, control the temperature in the ultra-low temperature refrigerator to -78°C, and then place the empty box of the freeze-drying box The temperature is lowered to -62°C at a rate of 12°C / min, and the fresh white fungus a that has been frozen after the first stage of pre-freezing treatment is quickly placed on the material rack in the pre-cooled vacuum freeze dryer cavity, and the second step is carried out. After two stages of freezing for ...

Embodiment 3

[0044] A drying method for fresh white fungus, comprising the following steps:

[0045]Step 1: raw material pretreatment; select 1 kg of whole fresh white fungus raw material, wherein the fresh white fungus has a water content of 85%, wash the fresh white fungus raw material with water to remove surface impurities, drain and obtain fresh white fungus a, and set aside;

[0046] Step 2: Sectional freezing; lay the fresh white fungus a in step 1 on a flat plate, put it into an ultra-low temperature refrigerator for the first stage of pre-freezing, control the temperature in the ultra-low temperature refrigerator to -80°C, and then place the empty box of the freeze-drying box The temperature is lowered to -65°C at a rate of 15°C / min, and the fresh white fungus a that has been frozen after the first stage of pre-freezing treatment is quickly placed on the material rack in the pre-cooled vacuum freeze dryer cavity, and the second step is carried out. After the second stage of freezi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com