Processing method of crisp mango strip leisure food

A technology of snack food and processing method, applied in the confectionery industry, food drying, food freezing and other directions, can solve the problems of high operating cost of freeze-drying equipment, poor product crispness, complex processing technology, etc. Time, good crispness, good puffing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

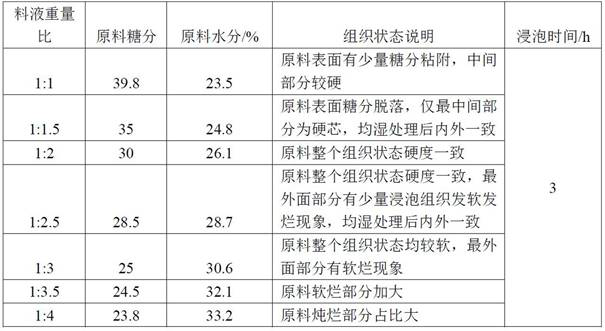

[0022] A processing method for crispy mango bar snack food, comprising the steps of:

[0023] (1) Pretreatment of raw materials: Select high-quality preserved mangoes, wash the sugar on the surface, soak them in clean water for 2 hours at a material-to-liquid weight ratio of 1:1.5, take them out, cut them into strips with a cross-section of 5*5mm, and drain them Surface moisture; the raw material of preserved mango is preserved fruit after high-sugar osmosis treatment, and the sugar content is 50-70%; the sugar content of preserved fruit raw material after soaking treatment is reduced to 25-40%;

[0024] (2) Humidity equalization: Wet the raw materials after draining the surface moisture in a closed environment for 10 hours, so that the moisture content in the raw materials is evenly distributed, and the temperature of the homogeneous humidity environment is 15°C;

[0025] (3) Frozen storage: put the wetted raw materials in a frozen storage at -10~-25°C;

[0026] (5) Puffing ...

Embodiment 2

[0030] A processing method for crispy mango bar snack food, comprising the steps of:

[0031] (1) Pretreatment of raw materials: Select high-quality preserved mangoes, wash the sugar on the surface, soak them in clean water for 3 hours at a material-to-liquid weight ratio of 1:2, take them out, cut them into strips with a cross-section of 10*10mm, and drain them Surface moisture; the raw material of preserved mango is preserved fruit after high-sugar osmosis treatment, and the sugar content is 50-70%; the sugar content of preserved fruit raw material after soaking treatment is reduced to 25-40%;

[0032] (2) Humidity equalization: Wet the raw materials after draining the surface moisture in a closed environment for 24 hours, so that the moisture content in the raw materials is evenly distributed, and the temperature of the homogeneous humidity environment is 25°C;

[0033] (3) Frozen storage: put the wetted raw materials in a frozen storage at -10~-25°C;

[0034] (5) Puffing ...

Embodiment 3

[0037] A processing method for crispy mango bar snack food, comprising the steps of:

[0038] (1) Pretreatment of raw materials: Select high-quality preserved mangoes, wash the sugar on the surface, soak in clean water for 6 hours at a material-to-liquid weight ratio of 1:2.5, take them out, cut them into strips with a cross-section of 8*8mm, and drain them Surface moisture; the raw material of preserved mango is preserved fruit after high-sugar osmosis treatment, and the sugar content is 50-70%; the sugar content of preserved fruit raw material after soaking treatment is reduced to 25-40%;

[0039] (2) Humidity equalization: Wet the raw materials after draining the surface moisture in a closed environment for 14 hours, so that the moisture content in the raw materials is evenly distributed, and the temperature of the homogeneous humidity environment is 20°C;

[0040] (3) Frozen storage: put the wet raw materials into -25°C for frozen storage;

[0041] (5) Puffing and drying:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com