Flavor-enhanced citrus pulp powder as well as preparation method and application thereof

A technology for pulp powder and citrus, applied in the field of food processing, can solve the problems such as the loss of flavor of citrus pulp powder, and achieve the effects of enhancing or modifying the flavor of food, broad application value and market prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

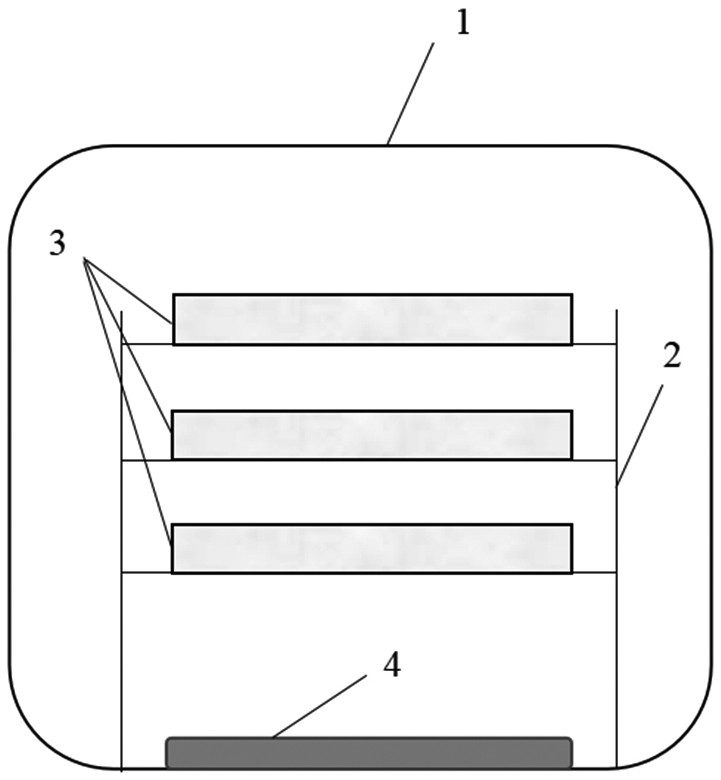

Image

Examples

Embodiment 1

[0030] In this embodiment, sweet orange juice is used as a raw material to prepare flavor-enhancing sweet orange pulp powder. The specific method is as follows:

[0031] Step 1, sweet orange juice pretreatment

[0032] After the sweet orange juice is filtered through a 0.4mm filter to remove the large-sized sweet orange pulp, it is then centrifuged at 8000rpm / min to obtain the remaining sweet orange pulp, and the sweet orange pulp is re-dispersed in water to remove the soluble sugar adhering to the surface of the pulp. Then centrifuge again, repeat the steps of dispersing and centrifuging twice, and finally obtain sweet orange pulp without soluble sugar, and then adopt a freeze-drying method to obtain sweet orange pulp powder.

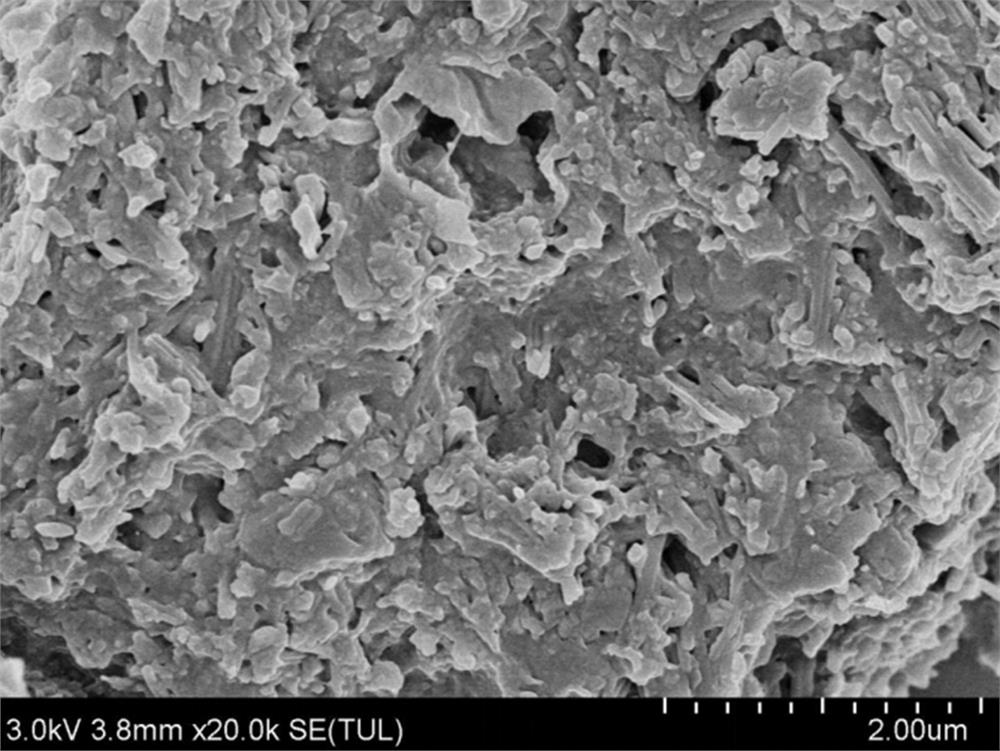

[0033] Detected by gas chromatography-mass spectrometry, the main non-volatile component content in the sweet orange pulp powder obtained by the pretreatment of step 1 is shown in Table 1, and its microstructure under a scanning electron microscope is ...

Embodiment 2

[0043] In this embodiment, tangerine fruit juice is used as raw material to prepare tangerine pulp powder with enhanced flavor. The specific method is as follows:

[0044] Step 1, pretreatment of tangerine juice

[0045] After the tangerine juice is filtered through a 0.4mm filter to remove the large-sized tangerine pulp, it is centrifuged at 10,000rpm / min to obtain the remaining tangerine pulp, and the tangerine pulp is re-dispersed in water to remove the soluble sugar adhering to the surface of the tangerine pulp , and centrifuged again, so that through three times of dispersion and centrifugation steps, tangerine pulp without soluble sugar was obtained, and then freeze-drying method was used to obtain tangerine pulp powder.

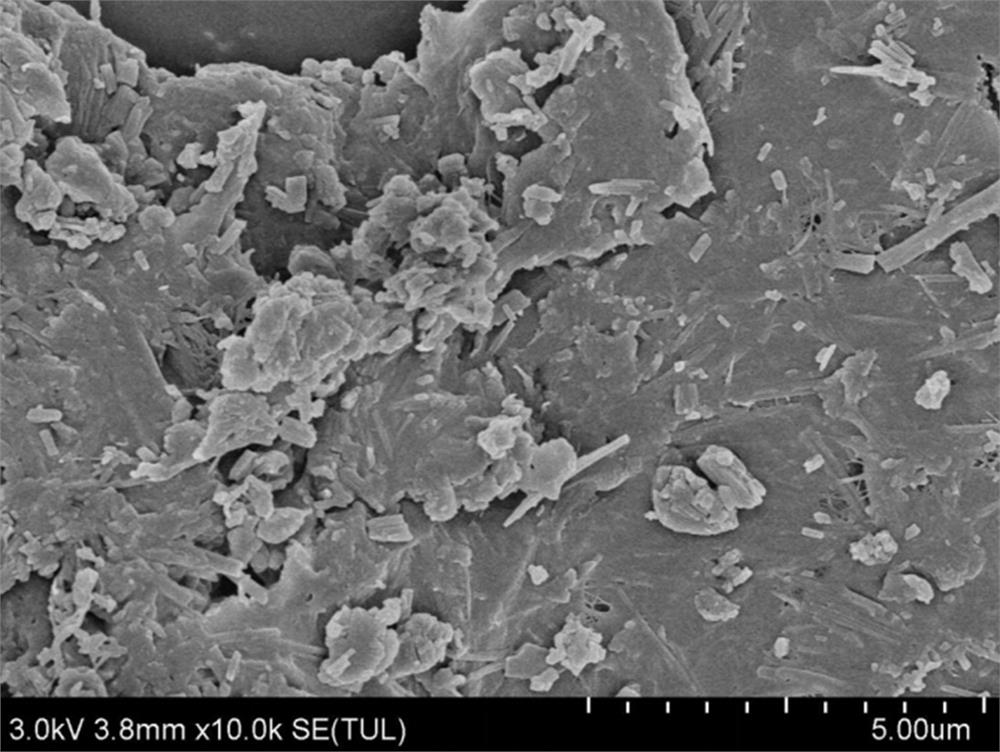

[0046] Detected by gas chromatography-mass spectrometry, the content of main non-volatile components in the tangerine pulp powder obtained from the pretreatment in step 1 is shown in Table 3, and its microstructure under a scanning electron microscope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com