Method and equipment for resource utilization of waste resin powder

A waste resin and recycling technology, applied in recycling technology, plastic recycling, etc., can solve the problems of wasting resin powder resources, unable to recycle resin powder resources, and multi-cost, so as to improve resource utilization, reduce labor burden, Simple and clear process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

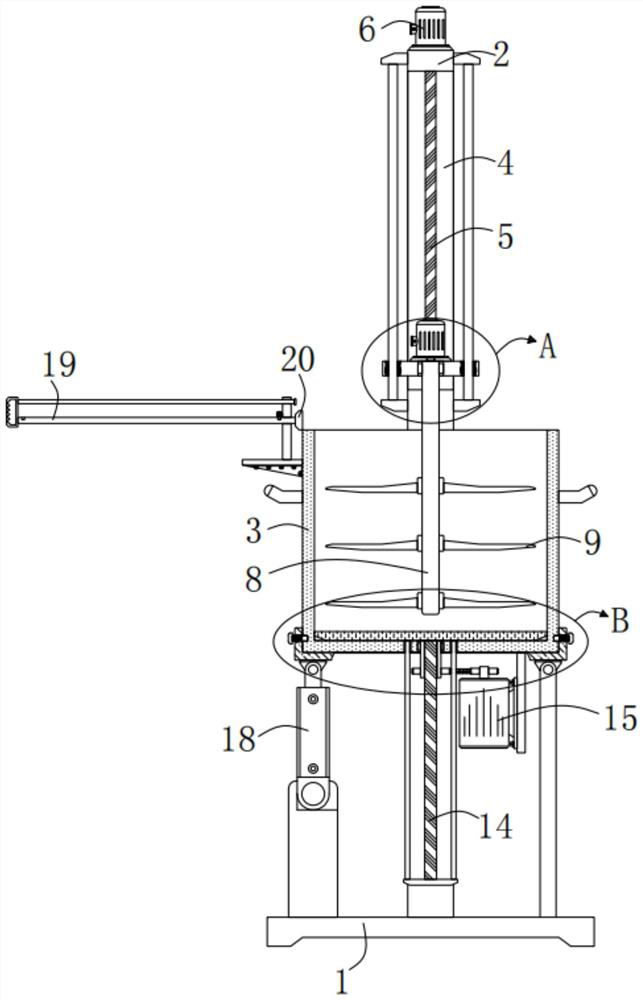

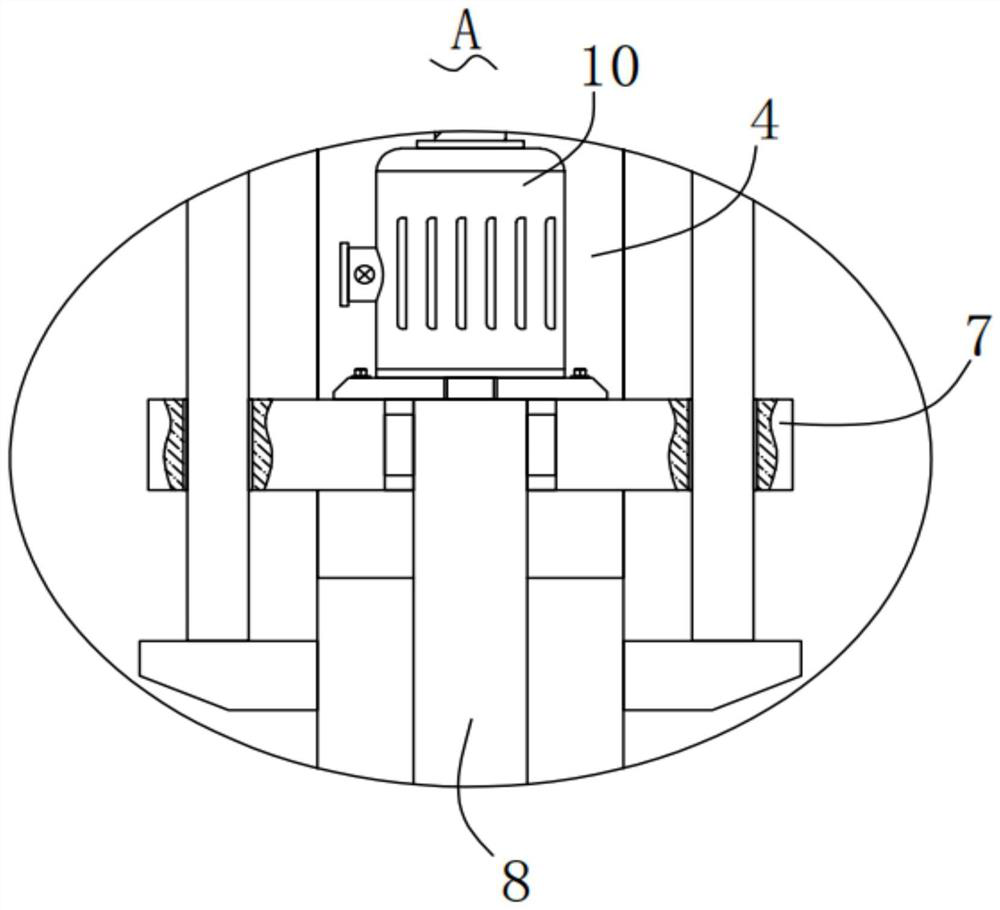

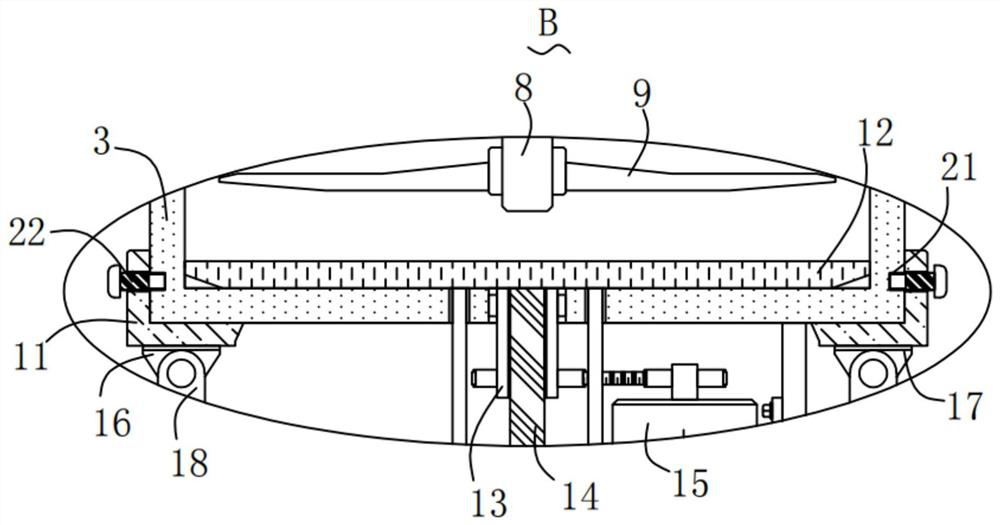

[0030] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 The front view of the equipment for resource utilization of waste resin powder provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 The enlarged schematic diagram of part B shown; Figure 4 A schematic diagram of the connection structure of the push bar and the push rod in the waste resin powder resource utilization equipment provided by the present invention; Figure 5 It is a schematic diagram of the side view structure of the support seat in the waste resin powder resource utilization equipment provided by the present invention. The method for resource utilization of waste resin powder comprises the following steps:

[0031] S1: Take out the waste resin powder, curing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com