Method for recovering phenol and acetophenone in phenol tar

A recovery method, the technology of acetophenone, applied in the field of recovery of phenol and acetophenone in phenol tar, can solve the problems of low catalytic cracking yield, easily damaged equipment, high residue viscosity, etc., and achieve simple equipment, reasonable process, The effect of easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

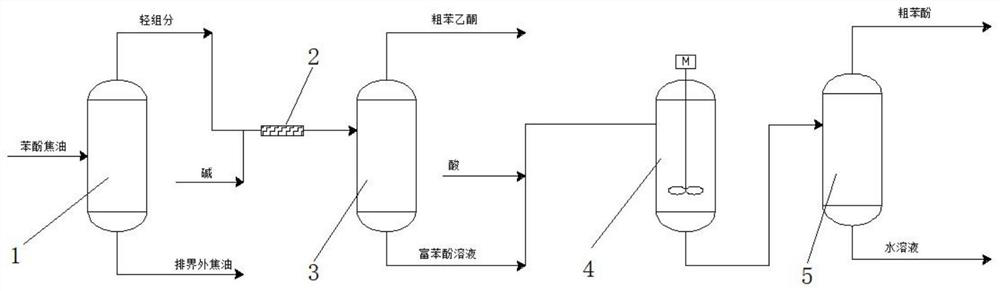

[0034] The phenol tar discharged from the phenol acetone unit is 1000kg / h, the temperature is 160 degrees, the content of phenol is 14.63%, the content of acetophenone is 18.6%, and the rest are high boiling substances. The pressure is 6kpaA, the jacket is heated by 10bar steam, the wiped film evaporator condenser discharges light components, the flow rate is 303kg / h, of which phenol 133kg / h and acetophenone 170kg / h, the bottom of the wiped film evaporator is residual phenol tar , The flow rate is 697kg / h.

[0035] The distilled light components and 13kg / h of 20wt% sodium hydroxide solution are mixed through a static mixer and then enter the chromatograph, phenol reacts with sodium hydroxide to generate sodium phenate, which is dissolved in water, and the upper part of the chromatograph is discharged rich in The component of acetophenone, the flow rate 170kg / h, is sent to the acetophenone rectification tower, the top discharges the light component 3kg / h, the side line extracts...

Embodiment 2

[0037] The phenol tar discharged from the phenol acetone unit is 1000kg / h, the temperature is 120 degrees, the content of phenol is 5%, the content of acetophenone is 30%, and the rest is high boiling matter, which enters the flash tank. The operating temperature of the flash tank is 120 degrees, and the operating pressure is 0.1 kpaA, the bottom of the flash tank is heated by a thermosiphon reboiler, the heating medium is 10bar steam, and there is a condenser on the top of the flash tank to discharge light components. h, the bottom of the flash tank is residual phenol tar, with a flow rate of 697kg / h.

[0038] The distilled light component and 3kg / h of 20wt% potassium hydroxide solution are mixed through a static mixer and then enter the chromatograph, phenol reacts with sodium hydroxide to generate sodium phenate, which is dissolved in water, and the upper part of the chromatograph discharges rich The component of acetophenone, the flow rate 170kg / h, is sent to the acetophen...

Embodiment 3

[0040] The phenol tar discharged from the phenol acetone unit is 1000kg / h, the temperature is 160 degrees, the content of phenol is 30%, the content of acetophenone is 5%, and the rest is high boiling matter, which enters the rectification tower. The operating temperature of the rectification tower is 220 degrees, and the operating pressure is 20kpaA ,The bottom of the flash tank is heated by a thermosiphon reboiler, the heating medium is 30bar steam, there is a condenser on the top of the rectification tower, and the light components are discharged, the flow rate is 320kg / h, of which phenol is 290kg / h and acetophenone is 30kg / h , the bottom of the rectifying tower is residual phenol tar, and the flow rate is 680kg / h.

[0041] The distilled light components and 300kg / h of 20wt% ammonia solution are mixed through a static mixer and then enter the chromatograph. Components, with a flow rate of 30kg / h, are sent to the acetophenone rectifying tower, and the light components are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com