Preparation method and application of biological ink containing PRP

A bio-ink and liquid water technology, applied in the field of 3D bio-printing, can solve the problems of scarless skin healing and lack of personalized functions of products, and achieve superior clinical application potential, good biosafety and biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.5g of gelatin and 0.05g of sodium alginate into a small beaker, add 4.5ml of PBS buffer solution, seal the beaker, dissolve in a water bath at 40°C for 30 minutes, and gently stir with a glass rod until the solution is uniform Without solute particles, the liquid hydrogel is obtained; the hydrogel is treated in a high-pressure steam sterilizer at 121°C for 30 minutes, and after the sterilization is completed, it is equilibrated at room temperature for 1 hour, and then sealed and refrigerated at 4°C;

[0028] Dissolve 2.5g of calcium chloride solid powder in 100ml of deionized water, stir magnetically until fully dissolved, and after high-pressure steam sterilization, seal and store at 4°C to obtain the crosslinking agent;

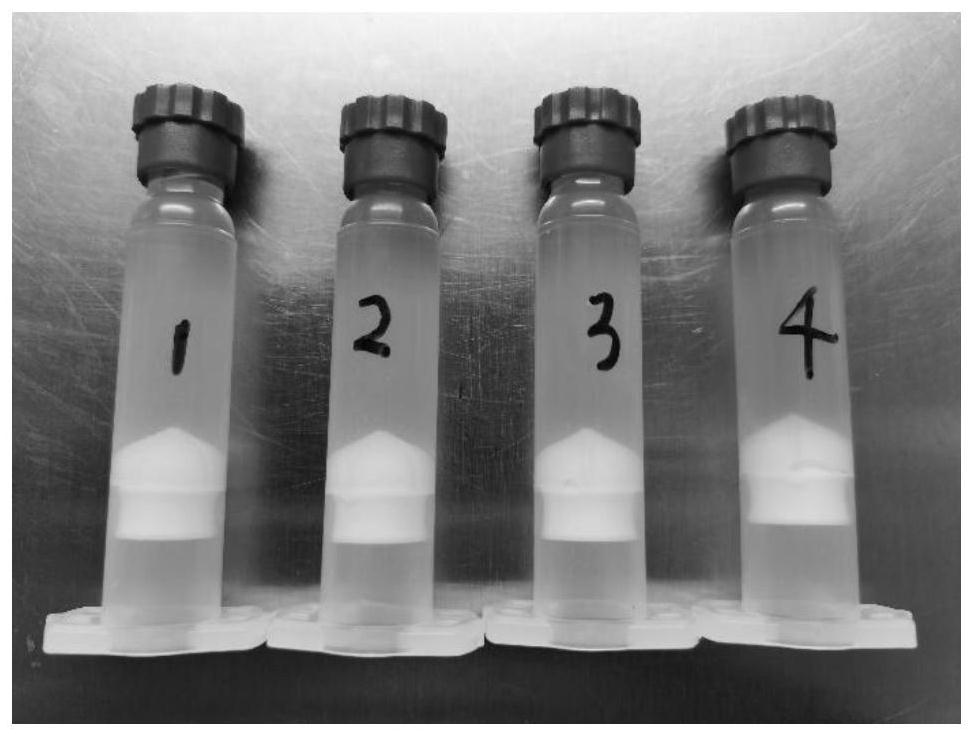

[0029] Mix 4.5ml of sterile gelatin-sodium alginate hydrogel, 0.375ml of PBS buffer and 0.125ml of PRP into a pre-filled syringe, and mix thoroughly with a sterile three-way device to obtain a PRP-containing bioink ( figure 1 No. 2 bioink); ...

Embodiment 2

[0033] Weigh 0.5g of gelatin and 0.05g of sodium alginate into a small beaker, add 4.5ml of PBS buffer solution, seal the beaker, dissolve in a water bath at 40°C for 30 minutes, and gently stir with a glass rod until the solution is uniform Without solute particles, the liquid hydrogel is obtained; the hydrogel is treated in a high-pressure steam sterilizer at 121°C for 30 minutes, and after the sterilization is completed, it is equilibrated at room temperature for 1 hour, and then sealed and refrigerated at 4°C;

[0034] Dissolve 2.5g of calcium chloride solid powder in 100ml of deionized water, stir magnetically until fully dissolved, and after high-pressure steam sterilization, seal and store at 4°C to obtain the crosslinking agent;

[0035] Mix 4.5ml of sterile gelatin-sodium alginate hydrogel, 0.25ml of PBS buffer and 0.25ml of PRP into a pre-filled syringe, and mix thoroughly with a sterile three-way device to obtain a PRP-containing bioink ( figure 1 No. 3 bioink);

...

Embodiment 3

[0038]Weigh 0.5g of gelatin and 0.05g of sodium alginate into a small beaker, add 4.5ml of PBS buffer solution, seal the beaker, dissolve in a water bath at 40°C for 30 minutes, and gently stir with a glass rod until the solution is uniform Without solute particles, the liquid hydrogel is obtained; the hydrogel is treated in a high-pressure steam sterilizer at 121°C for 30 minutes, and after the sterilization is completed, it is equilibrated at room temperature for 1 hour, and then sealed and refrigerated at 4°C;

[0039] Dissolve 2.5g of calcium chloride solid powder in 100ml of deionized water, stir magnetically until fully dissolved, and after high-pressure steam sterilization, seal and store at 4°C to obtain the crosslinking agent;

[0040] 4.5ml aseptic gelatin-sodium alginate hydrogel and 0.5mlPRP are packed in the prefilled syringe, utilize sterile three-way device to fully mix, promptly obtain the bioink containing PRP ( figure 1 No. 4 bioink);

[0041] Load the PRP-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com