Method for removing dissolved organic compounds from wastewater

A technology for organic compounds and sewage, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high investment in tertiary treatment equipment, improve the coagulation-flocculation process and reduce inorganic pollution. The effect of stabilizing the amount of mud and pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

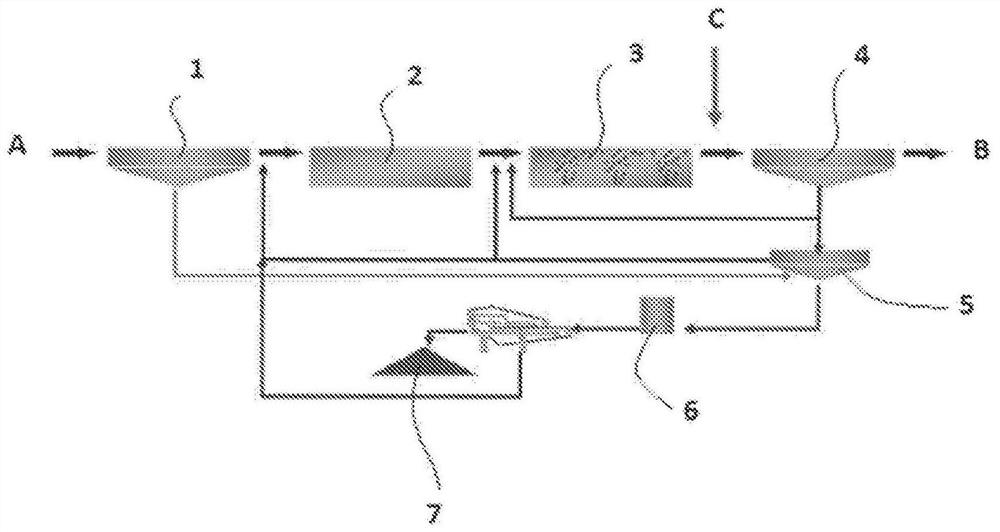

Image

Examples

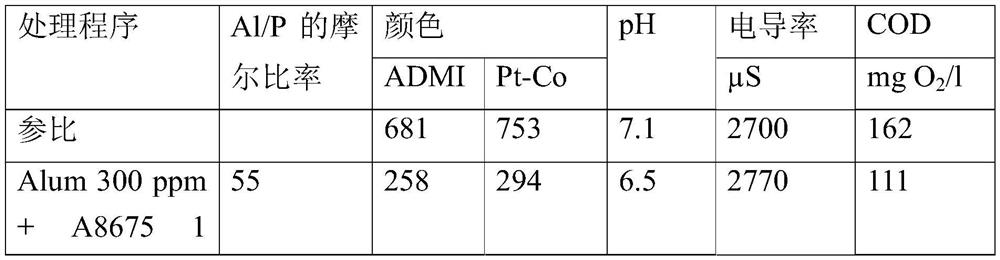

Embodiment 1

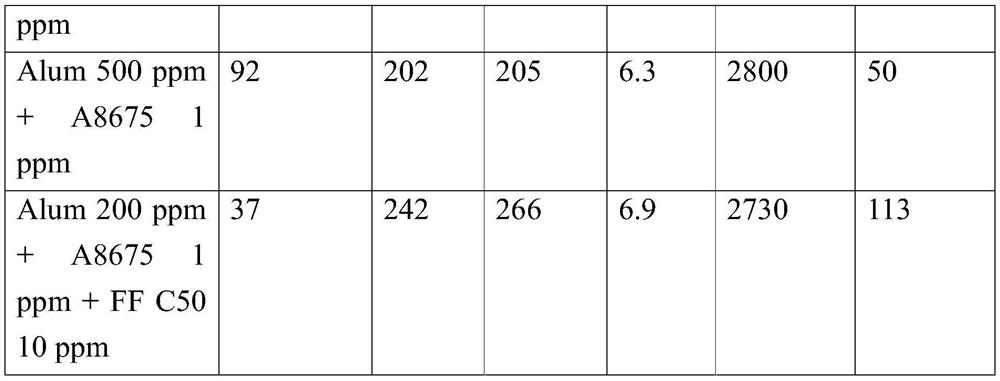

[0050]In this example, effluent from a paper mill was treated with varying doses of a 4% solution of aluminum sulfate (Alum) and anionic FennoPol A 8675 polymer flocculant (Kemira Oyj) dissolved in water to form a 0.1% solution combination, or

[0051] -4% aluminum sulfate (Alum) solution and anionic FennoPol A 8675 polymer flocculant (Kemira Oyj) dissolved in water to form a 0.1% solution and cationic polyamine coagulant (Fennofix FF C50, Kemira Oyj) dissolved in water to form A combination of 0.1% solutions is formed.

[0052] The reference measurement is the outlet of the secondary clarifier without any chemical addition.

[0053] The soluble phosphorus content of sewage is 0.25mg / L.

[0054] Approximately 30 L of effluent was collected to be able to use the same effluent sample for all tests. Sewage was stored in cold storage before starting the test. Homogenize the whole batch of samples and take 1L samples for coagulation test. Coagulation and flocculation tests wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com