Exhaust assembly, ventilation assembly and mask system

A component and mask technology, applied in respiratory masks, respirators, etc., can solve the problems of users being unable to speak and cough, poor comfort, and oppressing the bridge of the nose, etc., to improve the treatment effect and treatment compliance, clinical Qi and blood parameters are good, Compact and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

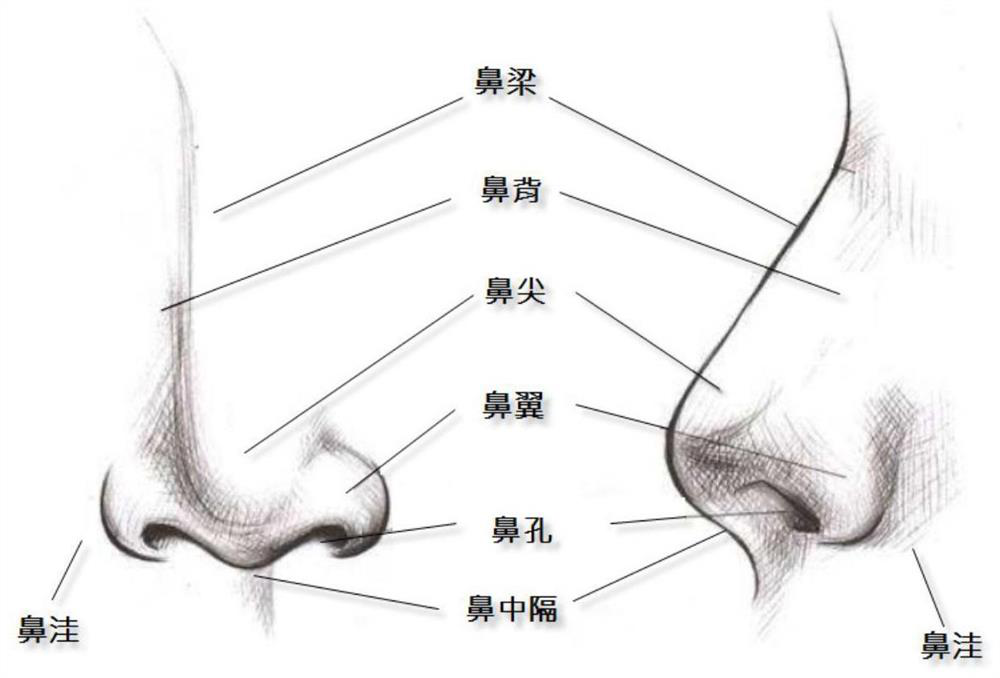

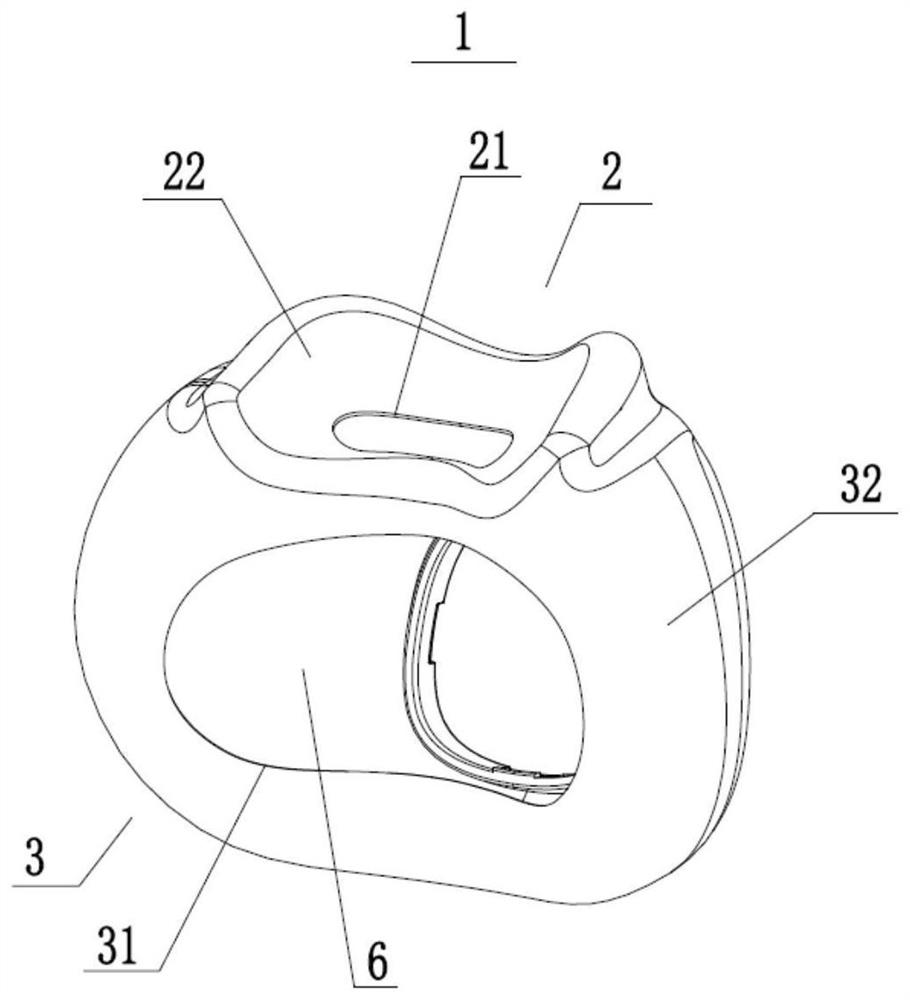

[0126] see figure 2 , the nasal structure 2 includes a nasal opening 21 communicating with the cavity 6 and a nasal cushion portion 22 surrounding the nasal opening 21 . Wherein, the nose opening 21 is configured to surround the underside of the user's nostrils in response to the oronasal liner 1 being worn by the user, and the nose cushion part 22 is adapted to fit around the user's nostrils for seal.

[0127] Specifically, referring to FIG. 5 , the nose cushion portion 22 includes a middle portion 23 arranged around the nasal opening 21 and nose side portions 24 arranged on both sides of the middle portion 23 , and the middle portion 23 responds to the pressure in the cavity 6 . The increase deforms to fit around the user's nostrils. Among them, the thickness of the middle part 23 can be 0.2-1.0mm, that is, the area where the middle part 23 is located is a thin film area, so it will expand and deform when it is pressed so that it can be close to the user's nostrils, so ev...

Embodiment 2

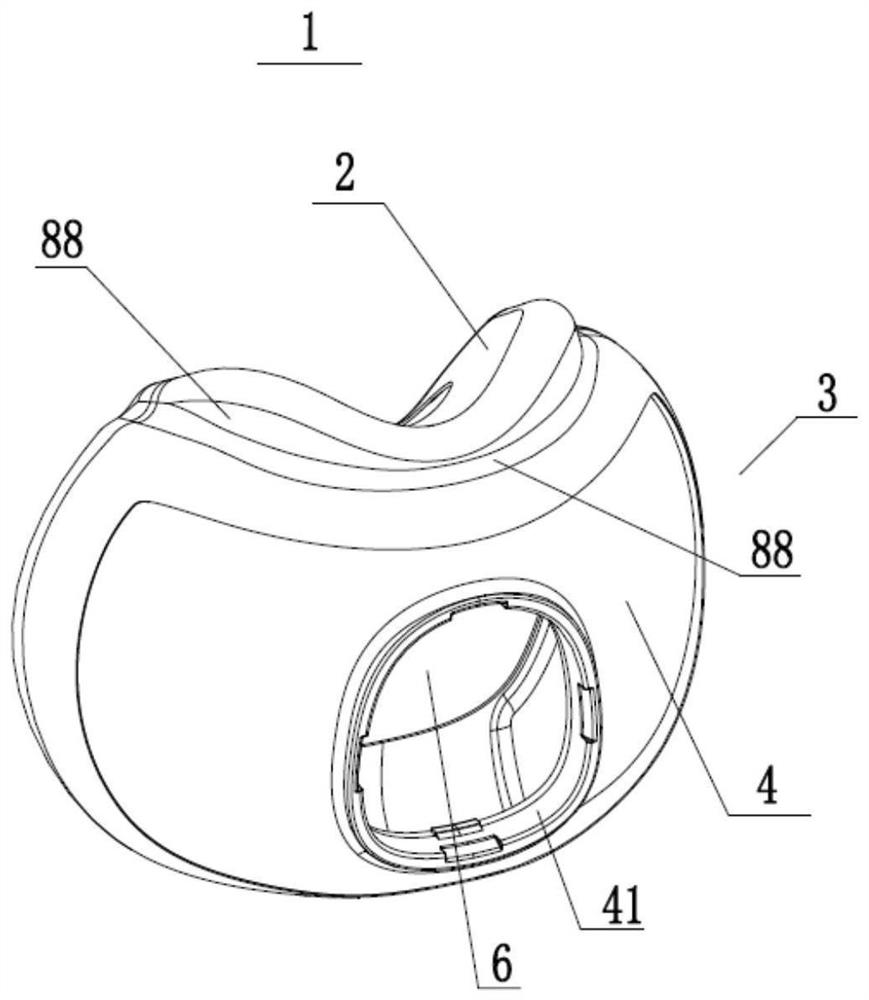

[0161] On the basis of the above-mentioned embodiment 1, the present invention provides a modified embodiment, that is, embodiment 2, such as Figure 12-Figure 15 shown. The following will only describe its differences from the foregoing embodiments, and the similarities will not be repeated here.

[0162] The difference between this embodiment and embodiment 1 is that the reinforcement structure 4 is made of the same material as the mouth structure body 3, and the two form an integral body. The material of the nasal structure 2 can also be the same as that of the reinforcing structure 4 and the oral structure 3, that is, the oronasal liner 1 is made of the same material as a whole.

[0163] For example, the material of the mouth and nose liner 1 can be one of materials such as silicone rubber, foam, thermoplastic elastomer, thermosetting material, foam, resin and textile.

[0164] When the material of the mouth and nose liner 1 can be silicone rubber, it is preferably silic...

Embodiment 3

[0166] On the basis of the above-mentioned embodiments, the present invention provides a modified embodiment, that is, embodiment 3. The following will only describe its differences from the foregoing embodiments, and the similarities will not be repeated here.

[0167] Please refer to Figure 27 , The difference between this embodiment and the above-mentioned embodiments is that the upper front side of the oronasal liner 1 is configured with an exhaust assembly 60 . The exhaust assembly 60 includes a first body (exhaust portion). The vent part may be a plurality of vent holes 61 provided on the oronasal liner 1 . Wherein, the first main body is integrally formed with the mouth and nose liner 1 .

[0168] The exhaust hole 61 is in the shape of a strip, an oblong shape, a circle, an oval or a special shape and the like. More specifically, the projection of the exhaust hole 61 on the normal plane P1 is in the form of a long strip, an oblong shape, a circle, an ellipse, a rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com