Fine treatment device for fiber reinforced polymer composite material

A fiber-reinforced, composite material technology is applied in the field of fiber-reinforced polymer composite material fine processing devices to achieve the effects of ensuring accuracy, facilitating overhaul and maintenance, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

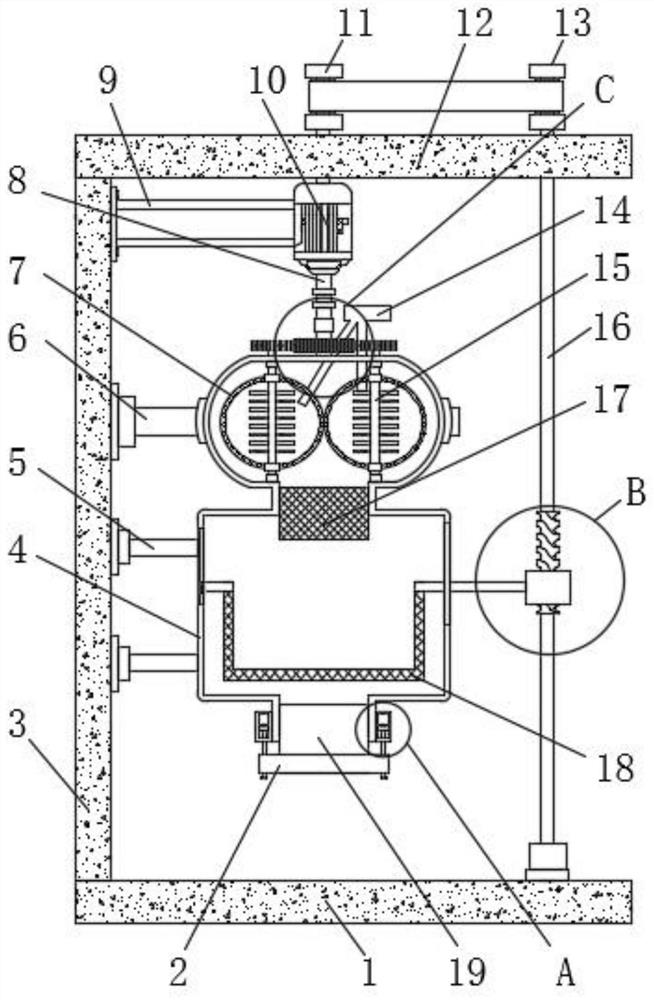

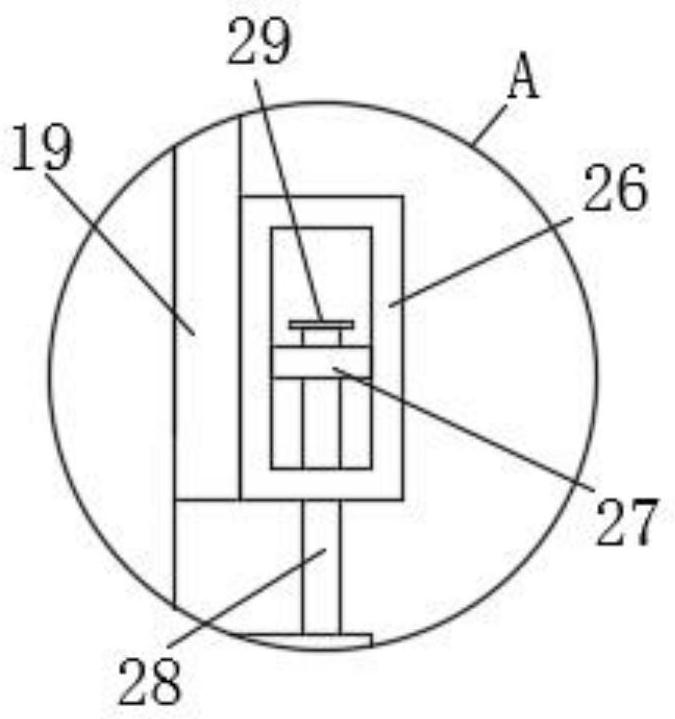

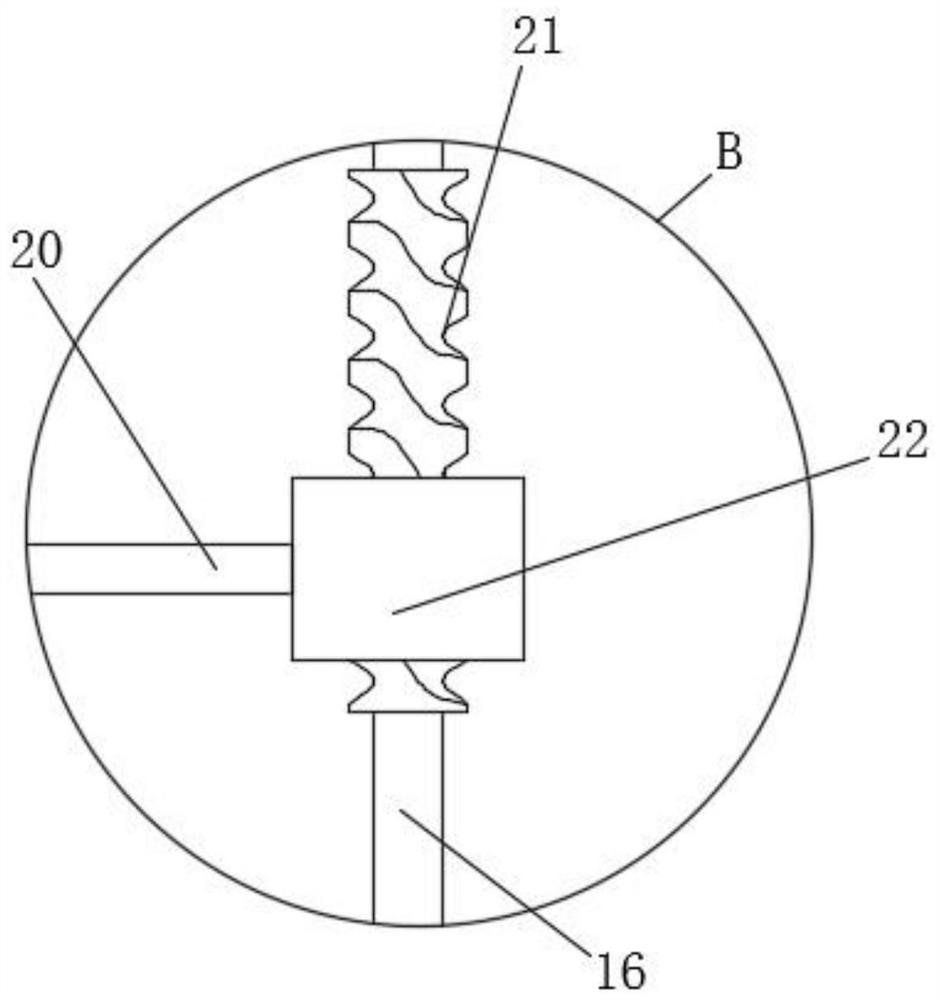

[0042] Embodiment 1: as figure 1 As shown, a fine processing device for fiber-reinforced polymer composite materials proposed by the present invention includes a base 1, a support column 3 is welded on the left side of the top of the base 1, and two first supports are welded on the right bottom of the support column 3 frame 5, the right end of the first support frame 5 is welded with a processing box body 4, the left side inner wall of the processing box body 4 is slidably connected with a sieve bucket 18, and the right end of the sieve bucket 18 is welded with a Movable bar 20, two pulverizing rollers 15 are sleeved on the top of processing box body 4, and one end of pulverizing roller 15 is positioned at processing box body 4 inside and one side inner wall of processing box body 4 is rotationally connected, and the outer ring of pulverizing roller 15 is welded with The tops of the crushing tank 7 and the crushing roller 15 are welded with a first gear 24 .

Embodiment 2

[0043] Embodiment 2: as figure 1 , Figure 4 As shown, the top of the processing box 4 is sleeved with a feed pipe 14 that runs through and extends into the crushing tank 7, and the outer ring of the crushing roller 15 is welded with a plurality of crushing blades arranged in a rectangular array. The top of the outer ring is welded with a second support frame 6, the top of the processing box 4 is rotatably connected with a first gear 24, the top of the first gear 24 is welded with a flange tube 23, and the top of the flange tube 23 is welded with a rotating shaft 8 to support The top right side of the column 3 is fixed with a third support frame 9 by bolts, and the end of the third support frame 9 away from the support column 3 is welded with a biaxial motor 10, and the bottom output end of the biaxial motor 10 is far away from the rotating shaft 8 One end of 23 is welded, and the middle part of both sides inner walls of processing box body 4 is welded with filter box 17.

Embodiment 3

[0044] Embodiment 3: as figure 1 and Figure 7-9 As shown, the rear side of the processing box 4 is provided with a dust removal box 32, a connecting pipe 33 is provided between the dust removal box 32 and the processing box 4, and the side wall of the dust removal box 32 is provided with a through hole 3201. One end of the connecting pipe 33 runs through the through hole 3201 and communicates with the interior of the dust removal box 32. The side wall of the miscellaneous removal box 32 is provided with a mechanism for easy disassembly. The mechanism for easy removal includes a positioning plate 35, a guide plate 36, a limit plate 37, and a sleeve spring 38 , insertion rod 39 and card slot 3401, the positioning plate 35 is fixedly installed on the side wall of the dust removal box 32, one end of the guide plate 36 runs through the positioning plate 35 and is slidingly connected with it, and the insertion rod 39 is fixedly installed, and the guide plate 36 is another One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com