Warm-mixed high-viscosity modified asphalt with low dissipation energy as well as preparation method and application thereof

A modified asphalt, warm-mixed and high-viscosity technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of insufficient road performance, exhaust gas and dust emissions, and increased energy consumption, so as to reduce energy consumption The effect of reducing consumption, reducing internal heat, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

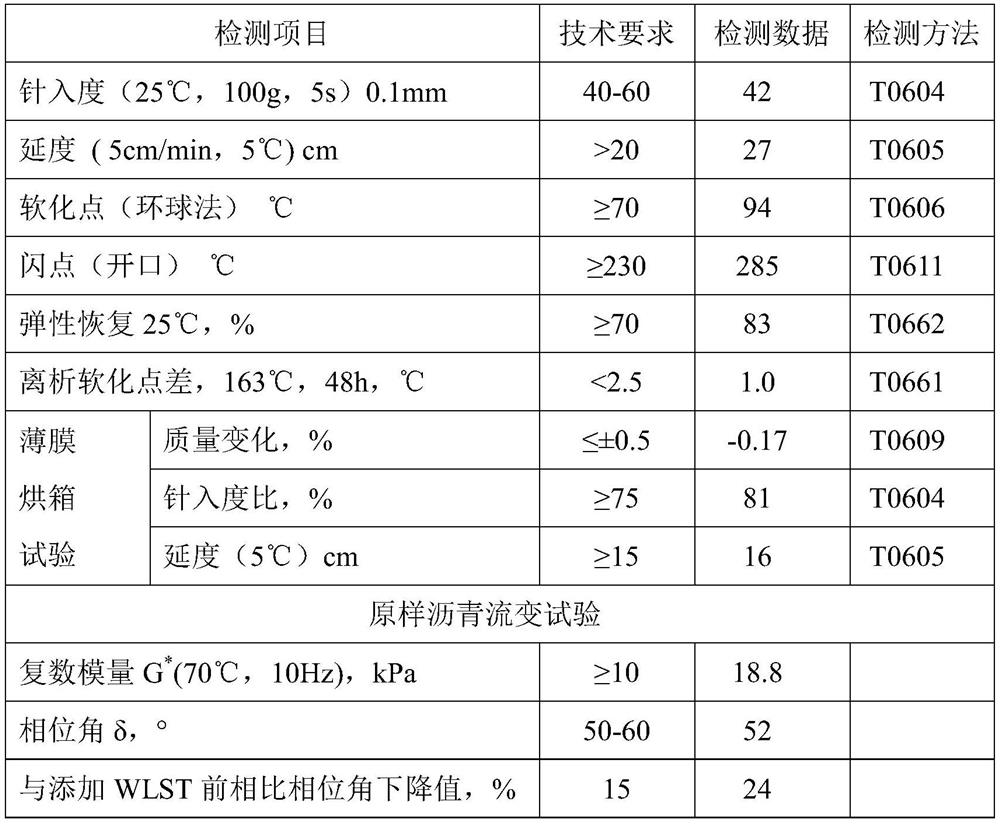

Embodiment 1

[0034] Example 1 A low-dissipation energy warm-mix high-viscosity modified asphalt and its preparation method

[0035] (1) First, mix hydrogenated styrene-butadiene rubber HSBR and SBS at a ratio of 35%:65%, and grind the mixture to 30-50 mesh with a high-pressure mill to obtain elastomer particles A.

[0036](2) Carboxyl multi-walled carbon nanotubes, anti-stripping agent and plasticizer were mixed in a small mixer for 5 minutes at a ratio of 45%: 25%: 30%, and the rotating speed was 400r / min to obtain a WLST modifier;

[0037] The length of the carboxyl multi-walled carbon nanotubes does not exceed 1000nm, and the aspect ratio is greater than 100; the anti-stripping agent is acetamide tetraacetic acid disodium salt; the plasticizer is dioctyl phthalate .

[0038] (3) Mix and stir the blend of Span S-80, Span S-60 and Tween in the ratio of 25%: 30%: 45% in a beaker, and the temperature of the water bath is 75°C to obtain the LTSP warm mixing agent.

[0039] (4) Mix the elas...

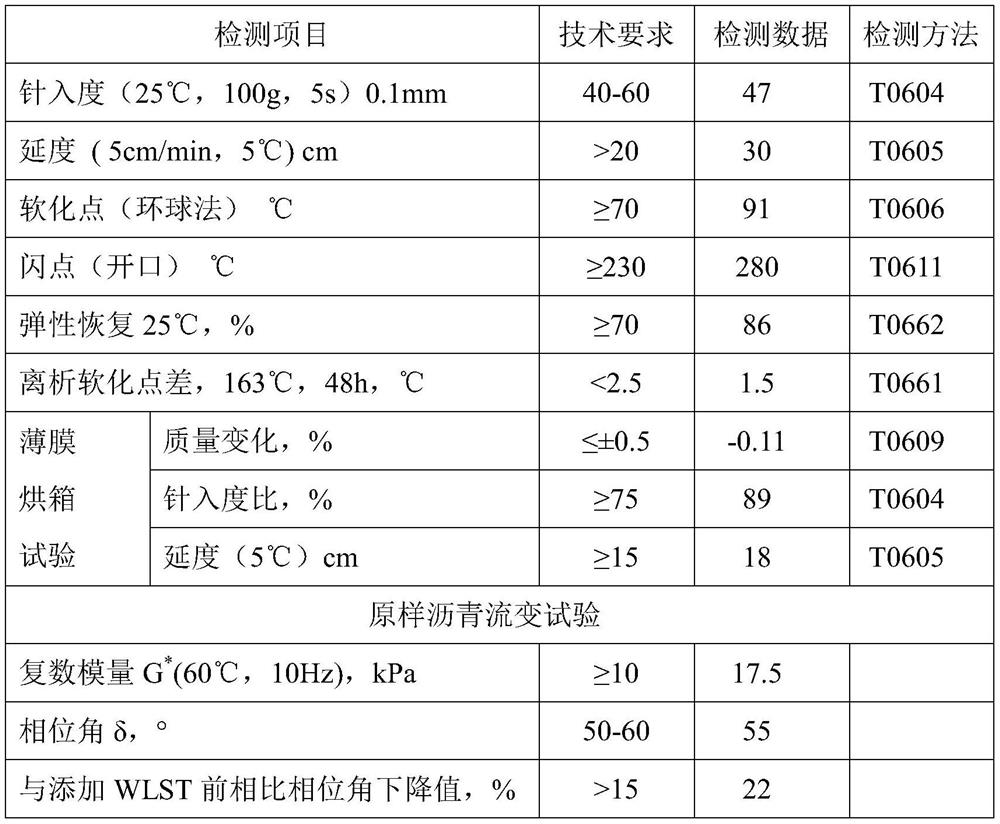

Embodiment 2

[0045] Example 2 A low-dissipation energy warm-mix high-viscosity modified asphalt and its preparation method

[0046] (1) First, mix hydrogenated styrene-butadiene rubber HSBR and SBS at a ratio of 45%:55%, and grind the mixture to 30-50 mesh with a high-pressure mill to obtain elastomer particles A.

[0047] (2) Carboxyl multi-walled carbon nanotubes, anti-stripping agent and plasticizer were mixed in a small mixer for 8 minutes at a ratio of 55%: 20%: 25%, and the rotating speed was 600r / min to obtain a WLST modifier;

[0048] The length of the carboxyl multi-walled carbon nanotubes is not more than 1000nm, and the aspect ratio is greater than 100; the anti-stripping agent is acetamide tetraacetic acid disodium salt; the plasticizer is dioctyl terephthalate .

[0049] (3) Mix and stir the blend of Span S-80, Span S-60 and Tween in the ratio of 20%: 25%: 55% in a beaker, and the temperature of the water bath is 80°C to obtain the LTSP warm mixing agent.

[0050] (4) Mix el...

Embodiment 3

[0057] 1. Preparation process of low-dissipation energy warm-mix high-viscosity modified asphalt:

[0058] (1) First, mix hydrogenated styrene-butadiene rubber HSBR and SBS at a ratio of 55:45, and grind the mixture to 30-50 mesh with a high-pressure mill to obtain elastomer particles A.

[0059] (2) Carboxyl multi-walled carbon nanotubes, anti-stripping agent and plasticizer were mixed in a small mixer for 10 minutes at a ratio of 65%: 15%: 20%, and the rotating speed was 600r / min to obtain a WLST modifier;

[0060] The anti-peeling agent is tetrasodium acetamide tetraacetate; the plasticizer is dibutyl phthalate.

[0061] (3) Mix and stir the blend of Span S-80, Span S-60 and Tween in the ratio of 30%: 35%: 35% in a beaker, and the temperature of the water bath is 85°C to obtain the LTSP warm mixing agent.

[0062] (4) Mix the elastomer particle A with the WLST modifier and the organic polymer internal lubricant at a ratio of 52%: 14%: 34% in a high-speed shear mixing devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| complex modulus | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com