Method for catalyzing light gasoline to reduce olefin

A technology for light gasoline and olefins, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products, etc., can solve the problems of high energy consumption and complex process flow, and achieve the effect of low energy consumption, simple separation process and increased output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

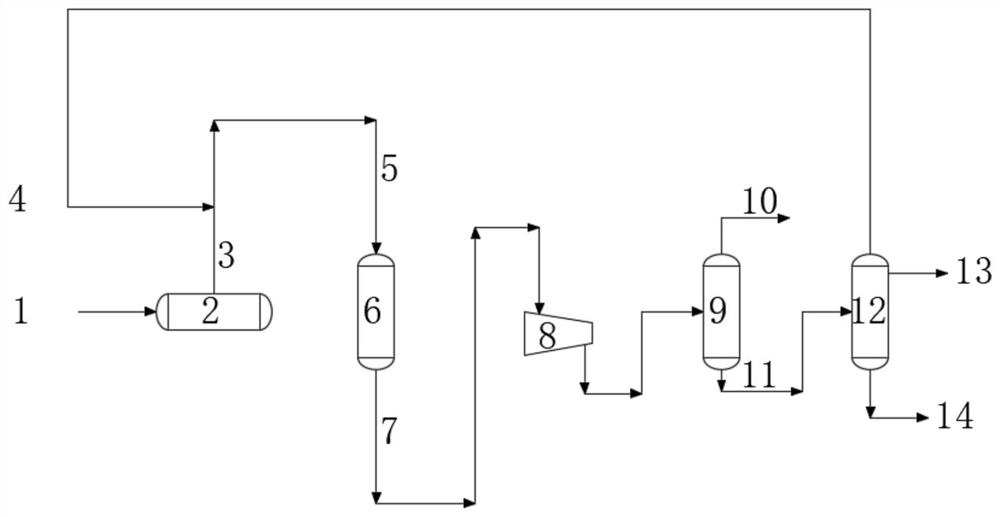

[0045] Provide a stream of catalysis light gasoline raw material that is 10 tons / hour, wherein the content of carbon five carbon hexaolefins is 50% (by mass fraction, the same below), the content of carbon five carbon six alkane is 45%, and the content of carbon four hydrocarbons is 5%. according to figure 1 The reaction shown in the process, wherein the reaction temperature of olefin catalytic cracking reaction is 550°C, the reaction pressure is 0.05MPaG, and the reaction space velocity is 10h -1 . The reaction product is pressurized to 2.0MPaG by the compressor, and then sent to the depropanizer. From the top of the depropanizer, 3.7 t / h of C3-feed was obtained with an olefin (ethylene+propylene) concentration of 81%. The operating pressure of the debutanizer is 0.35MPaG, the temperature at the top of the tower is 48°C, the temperature at the bottom of the tower is 92°C, and the number of trays is 38. The flow rate of the gas phase circulating material is 4 tons / hour, wh...

Embodiment 2

[0047] According to the conditions and steps described in Example 1, the C5C6O content in the light gasoline raw material is 60%, the C5C6A content is 35%, and the C4H content is 5%. The reaction temperature of olefin catalytic cracking is 540℃, the reaction pressure is 0.03MPaG, and the reaction space velocity is 7h -1 . The reaction product is pressurized to 2.0MPaG by the compressor, and then sent to the depropanizer. From the top of the depropanizer, 4.22 t / h of C3-material was obtained, in which the concentration of olefins (ethylene+propylene) was 83%. The operating pressure of the debutanizer is 0.5MPaG, the temperature at the top of the tower is 55°C, the temperature at the bottom of the tower is 100°C, and the number of trays is 45. The flow rate of the gas phase circulating material is 5 tons / hour, the concentration of C4 monoolefins is 36%, and the circulation ratio is 0.5. The output of liquefied gas is 0.89 tons / hour. The production of naphtha was 4.9 t / h with...

Embodiment 3

[0049] According to the conditions and steps described in Example 1, the C5C6O content in the light gasoline raw material is 40%, the C5C6A content is 55%, and the C4H content is 5%. The reaction temperature of olefin catalytic cracking is 560℃, the reaction pressure is 0.03MPaG, and the reaction space velocity is 5h -1 . The reaction product is pressurized to 2.0MPaG by the compressor, and then sent to the depropanizer. From the top of the depropanizer, 3.24 t / h of C3-material was obtained, in which the concentration of olefins (ethylene+propylene) was 81%. The operating pressure of the debutanizer is 0.45MPaG, the temperature at the top of the tower is 52°C, the temperature at the bottom of the tower is 96°C, and the number of trays is 25. The flow rate of the gas phase circulating material is 4 tons / hour, the concentration of C4 monoolefins is 33%, and the circulation ratio is 0.4. The output of liquefied gas is 0.82 tons / hour. Naphtha production was 5.94 t / h with an ol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com