Grouping type micro electrical discharge machining pulse power supply

A pulse power supply and electric spark technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve problems such as unsatisfactory industrial applications, unstable pulse parameters, and large energy consumption, so as to improve processing stability and discharge energy. Precisely controllable, avoid impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

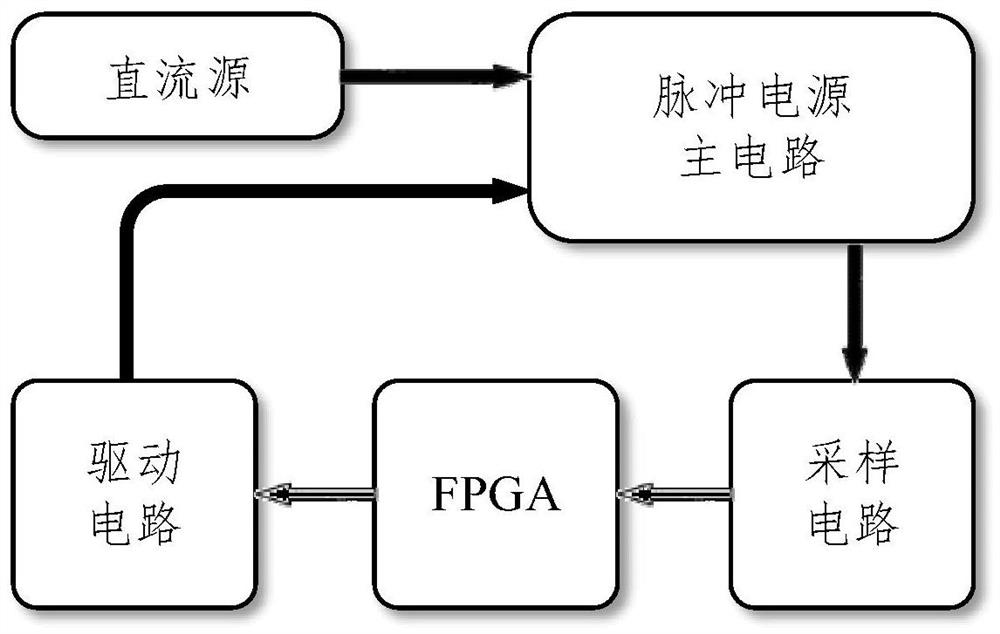

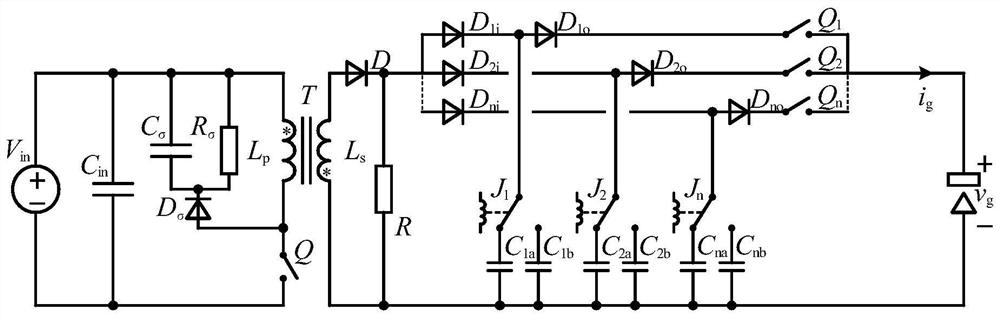

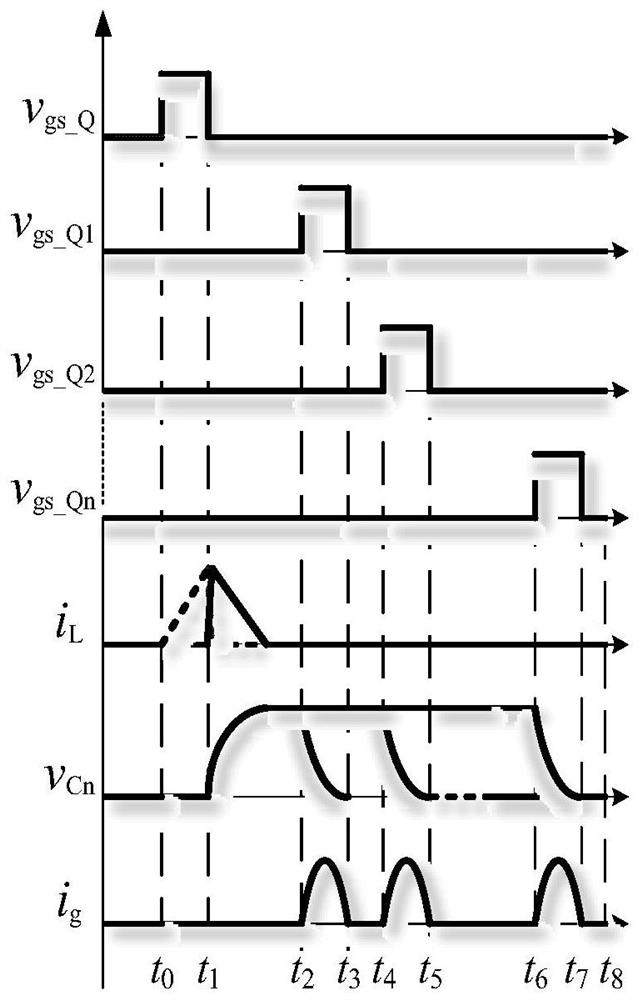

[0027] like figure 1 As shown, the present invention's grouped micro-EDM pulse power supply includes a DC source, a pulse power supply main circuit, a gap voltage and current sampling circuit, an FPGA controller, and a drive circuit; wherein, the pulse power supply main circuit is a gap output energy, and the sampling circuits respectively The voltage at both ends of the gap and the gap current are sampled, and the sampling signal is input to the FPGA control module. According to the processing requirements, the control signal is genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com