Arsenic-containing water body treatment method

A treatment method and water body technology, applied in the field of red mud resource utilization, can solve the problems of low utilization rate of red mud resources, secondary pollution, low utilization rate of acid waste water resources, etc., to reduce manpower, reduce residues, and optimize treatment and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

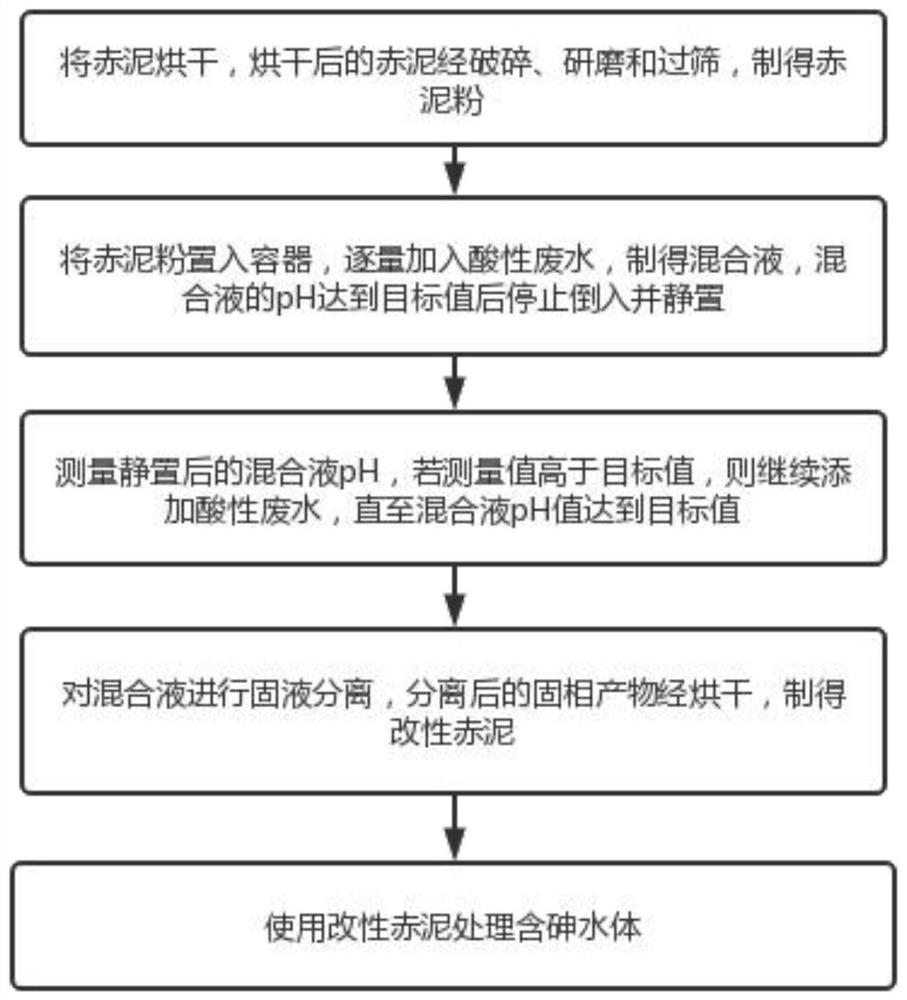

[0032] (1) Preparation of modified red mud

[0033] Using acid mine wastewater to modify red mud, the goal is to prepare three kinds of modified red mud with pH of 3, 4, and 5 respectively. The process is as follows:

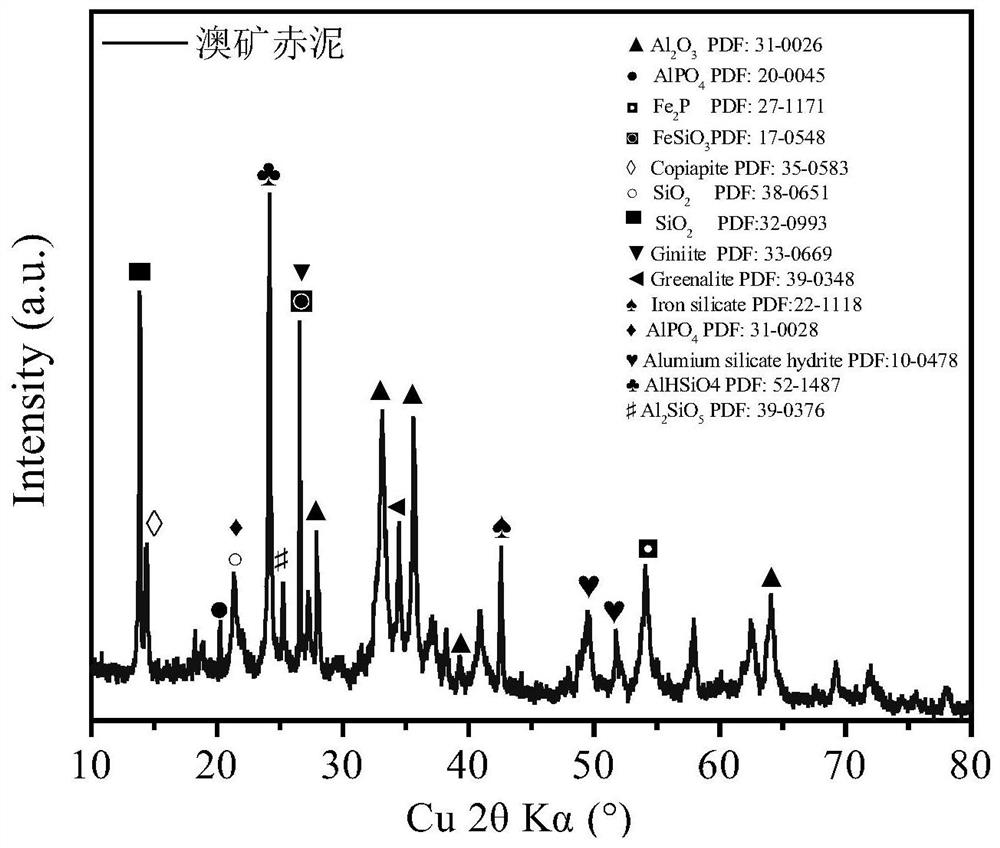

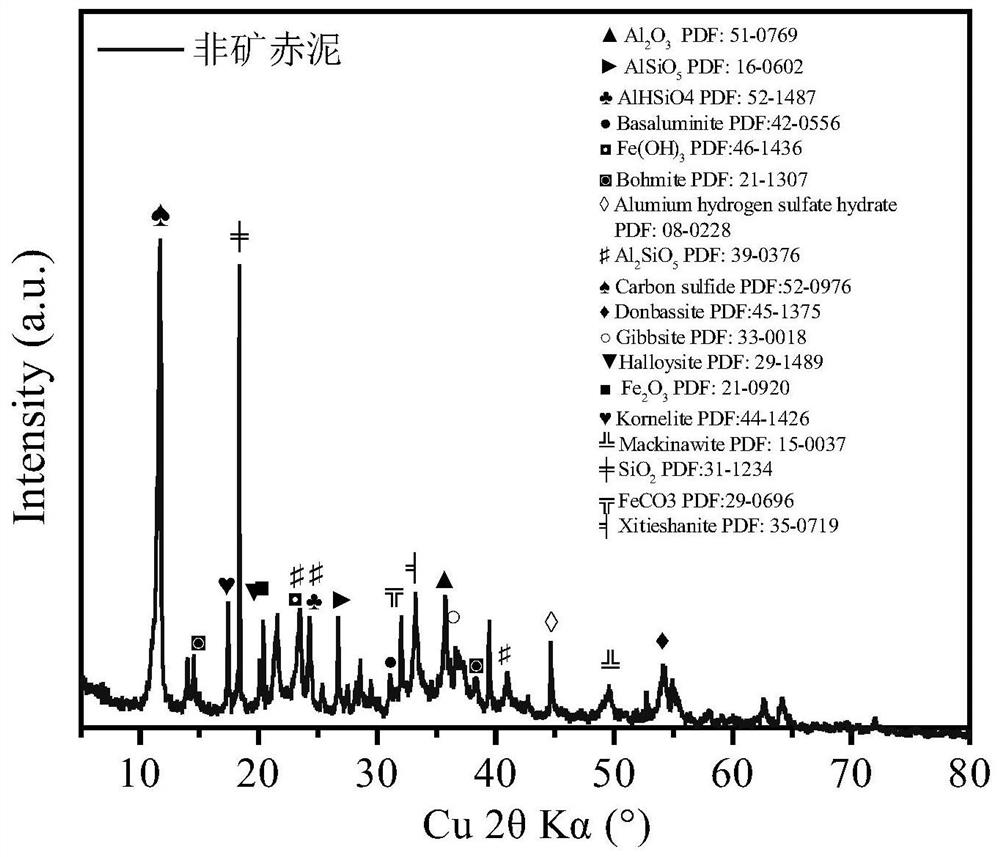

[0034] Dry and grind two kinds of red mud produced from African bauxite and Australian bauxite, and pass through a 2mm sieve;

[0035] Prepare 8 large 2L beakers, 10g of Australian ore red mud is weighed into each of 4 beakers, and 10g of non-mineral red mud is weighed into each of the remaining 4 beakers;

[0036] Fully shake the collected mine wastewater, filter it with filter paper, and gradually add it to the above-mentioned beaker, shake it while adding it, and measure the pH of the mixed solution at the same time until it reaches the target value;

[0037] After allowing the mixture to sit overnight, measure its pH accurately again. If the measured value is higher than the target value, it is necessary to add waste water again to reduce it until the targ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap