Nanocrystalline stainless steel for paper pulp millstone and preparation method thereof

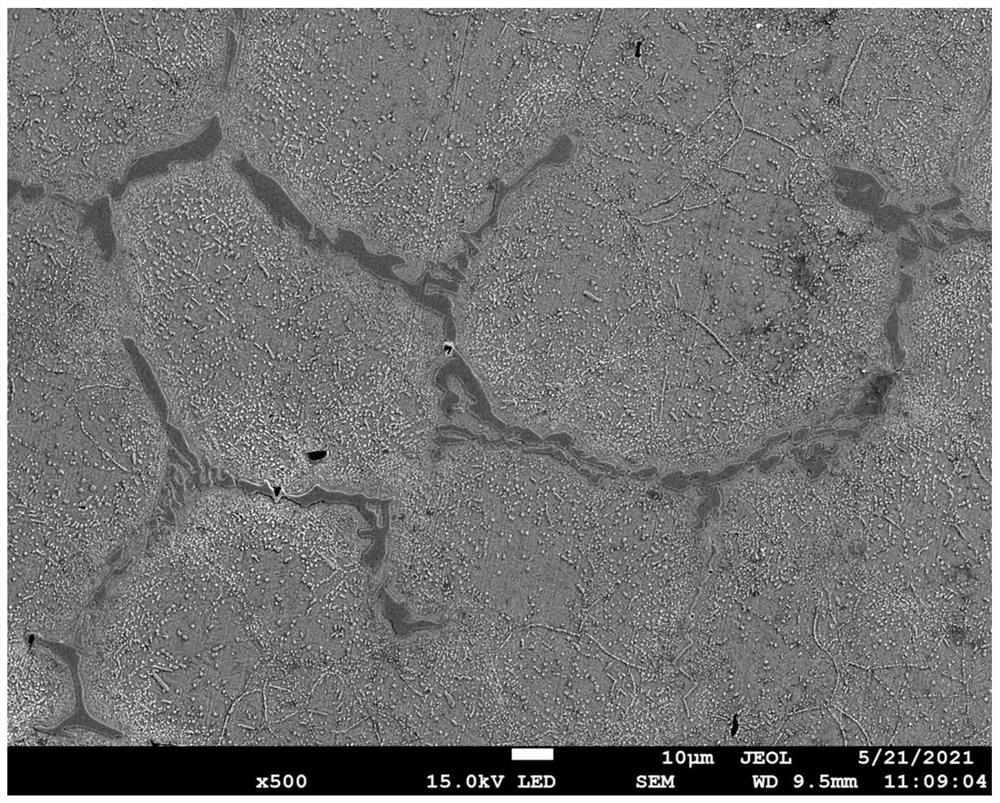

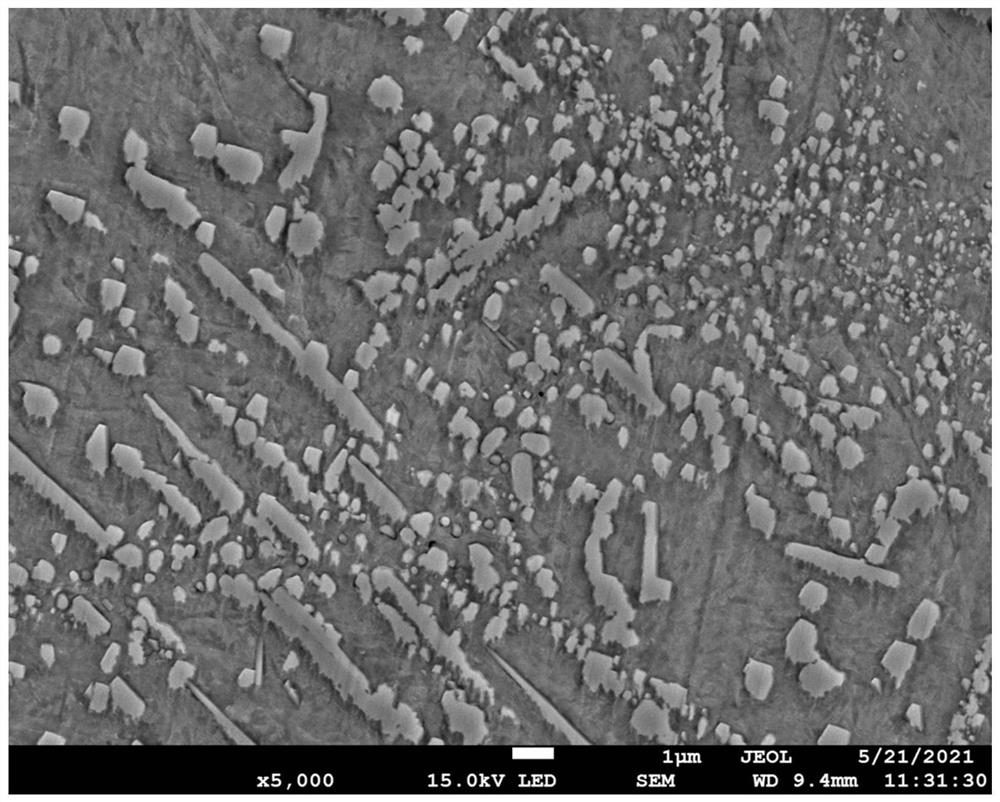

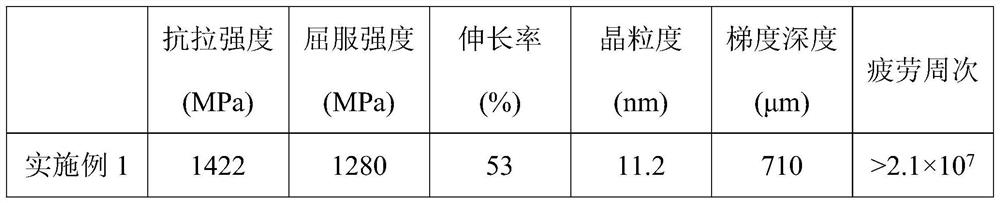

A nanocrystalline and stainless steel technology, applied in the field of papermaking, can solve problems such as low yield strength and poor wear resistance, achieve uniform carbide particle size, improve mechanical properties, fatigue properties, and excellent fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment provides a method for preparing nanocrystalline stainless steel used in pulp grinding discs, the preparation method comprising the following steps:

[0085] (1) The billet is prepared according to the formula quantity: the raw material ingot is obtained by smelting in a vacuum induction furnace, and then a billet with a thickness of 45 mm is obtained through blank forging and precision forging;

[0086] (2) The blank obtained in the hot rolling step (1) is heat-preserved at 700°C for 2.5 hours to obtain a hot-rolled material; the starting temperature of the hot rolling is 1220°C, and the finishing temperature is 1080°C; the total deformation of the hot rolling amount is 85%, and the single-pass deformation amount of the hot rolling is 19%;

[0087] (3) cold-rolling the hot-rolled material obtained in step (2), the total deformation of the cold-rolled treatment is 90%, and the deformation per pass is 15%, so as to obtain the cold-rolled material;

[0088...

Embodiment 2

[0093] This embodiment provides a method for preparing nanocrystalline stainless steel used in pulp grinding discs. The process steps of the preparation method are the same as those in Embodiment 1.

[0094] In terms of mass percentage, the nanocrystalline stainless steel described in this embodiment includes: C is 0.08wt%, Ni is 2.4wt%, Cu is 1.1wt%, Cr is 13.8wt%, Mn is 3.5wt%, Co is 2.5wt% , N is 0.18wt%, and the balance is Fe and unavoidable impurities; specifically, P≤50ppm, S≤50ppm, and O is less than or equal to 30ppm.

Embodiment 3

[0096] This embodiment provides a method for preparing nanocrystalline stainless steel used in pulp grinding discs. The process steps of the preparation method are the same as those in Embodiment 1.

[0097] In terms of mass percentage, the nanocrystalline stainless steel described in this embodiment includes: C is 0.1wt%, Ni is 2.7wt%, Cu is 1.1wt%, Cr is 13.4wt%, Mn is 4.5wt%, Co is 1.5wt% , N is 0.16wt%, and the balance is Fe and unavoidable impurities; specifically, P≤50ppm, S≤50ppm, and O is less than or equal to 30ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com