Manufacturing method of novel high-performance ultra-fine grain GH4169 metal turbine disc

A technology of GH4169 and a manufacturing method, applied in the field of high-performance ultra-fine grain GH4169 metal turbine disk manufacturing, to achieve the effects of avoiding fatigue fracture, refining grain structure, and excellent fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

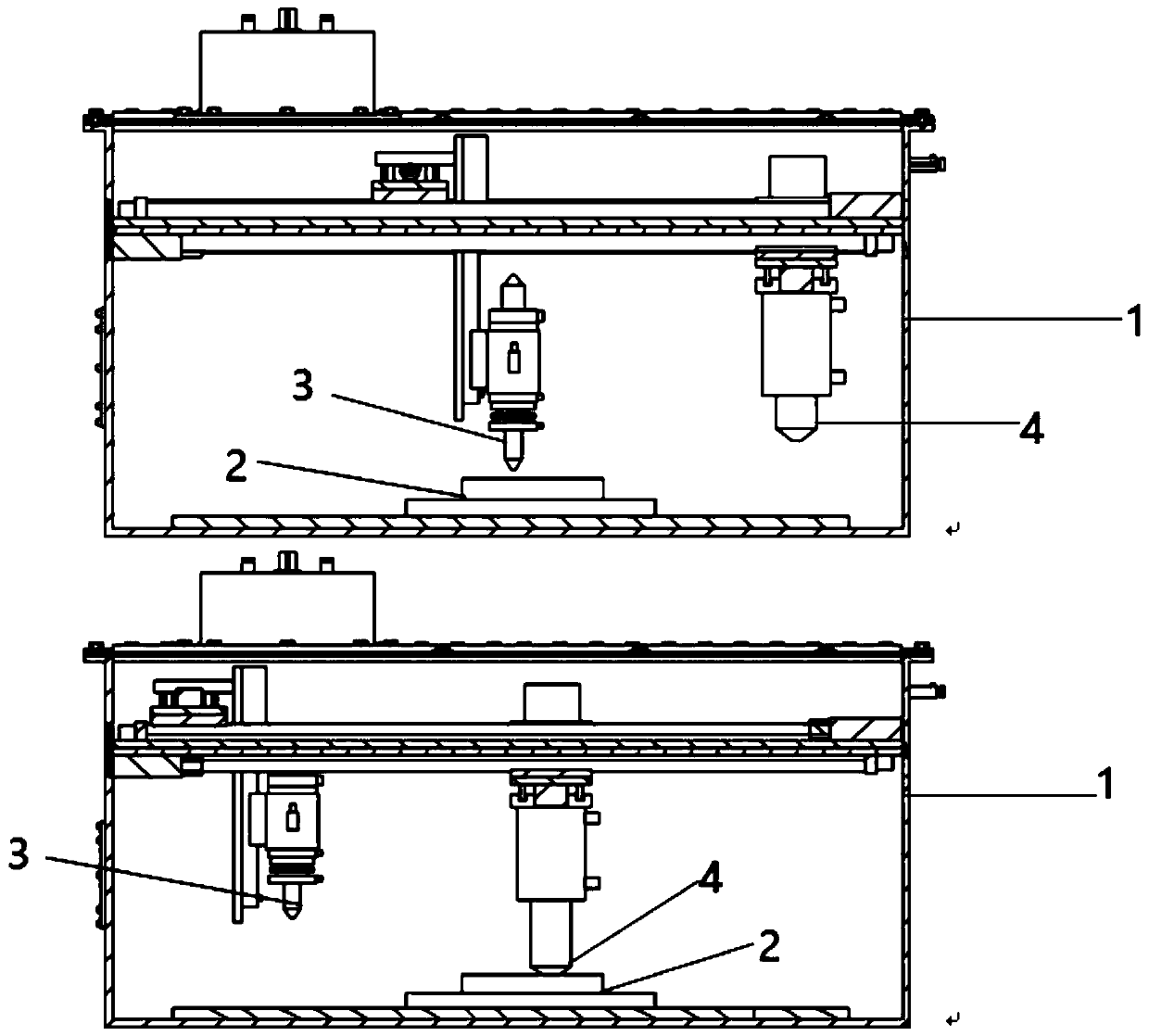

[0017] Such as figure 1 As shown, the GH4169 material alloy substrate 2 is placed in the inert gas protection box 1, and the box is sealed after being fixed with a card, and argon gas is introduced for protection, and the oxygen volume fraction is controlled to be lower than 6×10-5 to prevent the GH4169 alloy from being exposed to the laser. Oxidation during the rapid prototyping process, and then through the laser head 3, a high-precision three-way coaxial powder feeding system is used to perform laser three-dimensional forming of the GH4169 alloy turbine disk, following the forming trajectory until the first layer is fused; the laser process parameters are: Laser power: 3500W; Scanning speed: 5mm / s; Spot diameter: 4mm; Overlap rate: 40%; Powder feeding rate: 10g / min; Form GH4169 alloy laser cladding layer on GH4169 alloy substrate.

[0018] Continuous point forging is carried out on the above-mentioned GH4169 alloy cladding layer which has undergone laser melting, and the pl...

Embodiment 2

[0021] Put the GH4169 material alloy substrate 2 in the inert gas protection box 1, install the card and fix it, seal the box, pass in argon gas for protection, control the oxygen volume fraction below 6×10-5, and prevent the GH4169 alloy from being damaged during the laser rapid prototyping process Medium oxidation, and then through the laser head 3, adopt the high-precision three-way coaxial powder feeding system to carry out the laser three-dimensional forming of the GH4169 alloy turbine disk, follow the forming track until the first layer is fused; the laser process parameters are: laser power: 3500W; scanning Speed: 5mm / s; Spot diameter: 4mm; Overlap rate: 40%; Powder feeding rate: 10g / min; Form GH4169 alloy laser cladding layer on GH4169 alloy substrate.

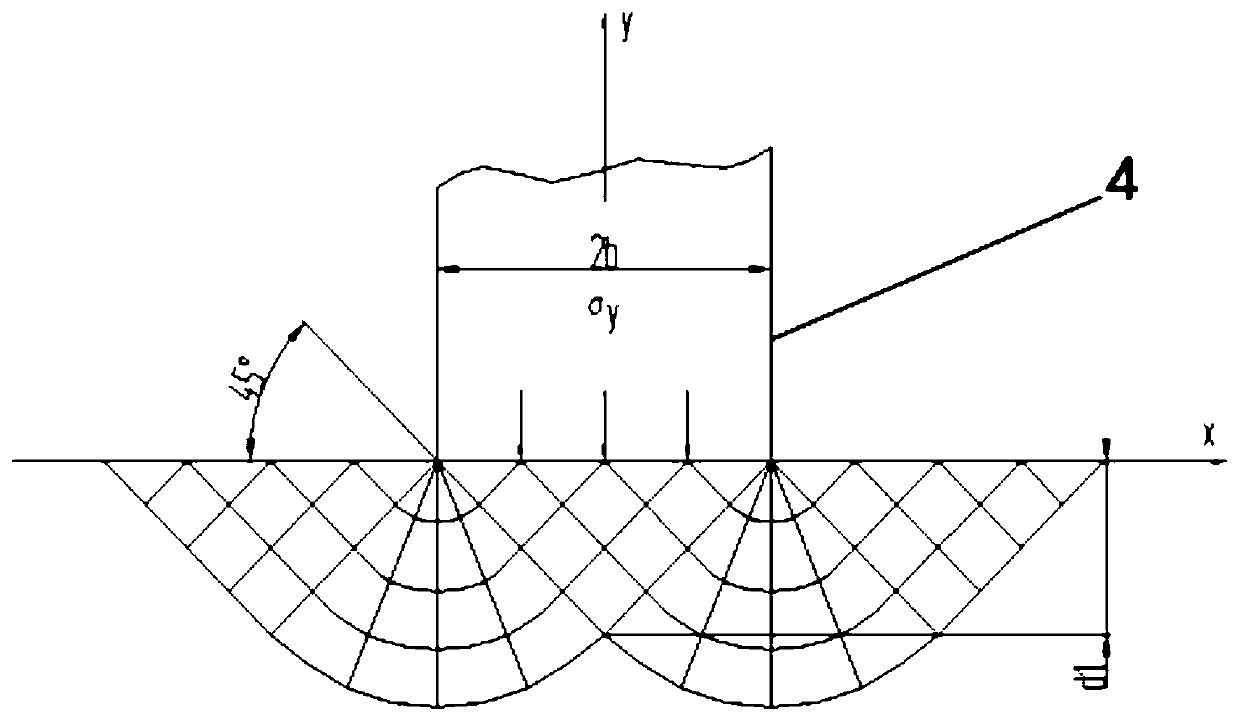

[0022]Continuous point forging is carried out on the above-mentioned GH4169 alloy cladding layer which has undergone laser melting, and the plane point forging is carried out by selecting the plane point pressure head 4...

Embodiment 3

[0024] Put the GH4169 material alloy substrate 2 in the inert gas protection box 1, install the card and fix it, seal the box, pass in argon gas for protection, control the oxygen volume fraction below 6×10-5, and prevent the GH4169 alloy from being damaged during the laser rapid prototyping process Medium oxidation, and then through the laser head 3, adopt the high-precision three-way coaxial powder feeding system to carry out the laser three-dimensional forming of the GH4169 alloy turbine disk, follow the forming track until the first layer is fused; the laser process parameters are: laser power: 3500W; scanning Speed: 5mm / s; Spot diameter: 4mm; Overlap rate: 40%; Powder feeding rate: 10g / min; Form GH4169 alloy laser cladding layer on GH4169 alloy substrate.

[0025] Continuous point-type forging is carried out on the above-mentioned GH4169 alloy cladding layer through laser melting, and a flat point-type indenter 4 is selected for flat point-type forging. The diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com