Forging method of GH4169 alloy ultrafine grain forging

A GH4169, ultra-fine grain technology, applied in the direction of metal processing equipment, etc., can solve the problems of failure to meet the standard requirements, fatigue performance of parts, etc., and achieve the effect of excellent fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

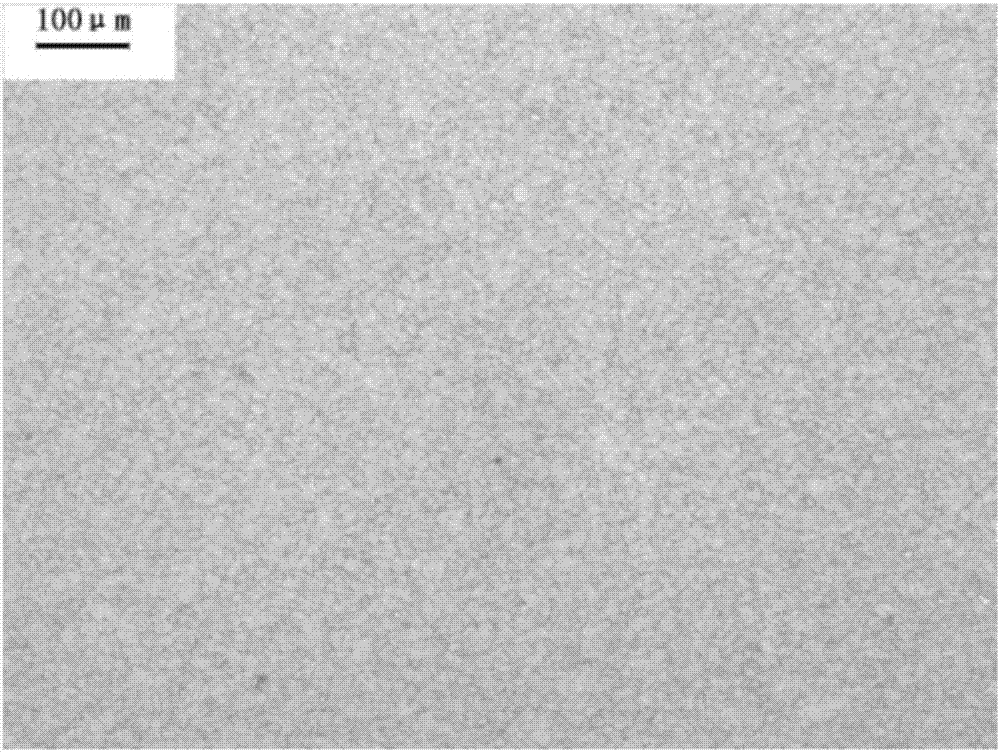

Image

Examples

Embodiment 1

[0015] Finished product specifications: Φ250×60mm thin wafer cake

[0016] 1. Use a Φ220mm round bar as the initial billet for pretreatment of δ phase precipitation. The pretreatment is carried out in an electric furnace. The treatment process is 910°C for 12 hours, and the furnace is air-cooled after treatment.

[0017] 2. The Φ220mm round bar blank is heated at 970°C, and the surface of the blank is covered with a heat-insulating cotton that can be pasted. Then, it is drawn in one direction on a 1200-ton fast forging machine, and it is drawn to Φ140mm in one fire. The forging ratio is 2.5, and the final forging temperature is It is 920°C.

[0018] 3. The Φ140mm round bar is polished on the surface to remove defects such as micro-cracks on the surface to ensure the surface quality of the finished product. Then cut to length to form die forging billet, the billet size is Φ130×270mm.

[0019] 4. Φ130×270mm is heated by an electric furnace at a heating temperature of 970°C. Th...

Embodiment 2

[0022] Finished product specifications: Φ250×60mm thin wafer cake

[0023] 1. Use a Φ140mm×280mm round bar as the initial billet for pretreatment of δ phase precipitation. The pretreatment is carried out in an electric furnace. The treatment process is 910°C for 12 hours, and it is air-cooled after treatment.

[0024] 2. The Φ140mm×280mm round bar blank is heated at 970°C, and the surface of the blank is covered with a heat-insulating cotton that can be pasted, and then upsetting is carried out on a 2,000-ton hydraulic press machine, upsetting 30%, and it is pulled out to Φ140mm×280mm by holding tongs, forged The ratio is 2.7, and the final forging temperature is 910°C.

[0025] 3. The Φ140mm round bar is polished on the surface to remove defects such as micro-cracks on the surface to ensure the surface quality of the finished product. Then cut to length to form die forging billet, the billet size is Φ130×270mm.

[0026] 4. Φ130×270mm is heated by an electric furnace at a he...

Embodiment 3

[0029] Finished product specifications: Φ300×70mm thin wafer cake

[0030] 1. Use a Φ250mm round bar as the initial billet for pretreatment of δ phase precipitation. The pretreatment is carried out in an electric furnace. The treatment process is 910°C for 12 hours, and the furnace is air-cooled after treatment.

[0031] 2. The Φ250mm round bar blank is heated at 970°C, and the surface of the blank is covered with a heat-insulating cotton that can be pasted. Then, it is drawn in one direction on a 1200-ton fast forging machine, and it is drawn to Φ160mm in one fire. The forging ratio is 2.4, and the final forging temperature is It is 920°C.

[0032] 3. The Φ160mm round bar is polished on the surface to remove defects such as micro-cracks on the surface to ensure the surface quality of the finished product. Then cut to length to form die forging billet, the billet size is Φ150×310mm.

[0033] 4. Φ150×310mm is heated by an electric furnace at a heating temperature of 970°C. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com