Tunneling magnetoresistance sensor and preparation method and use method thereof

A tunneling magnetoresistance and sensor technology, applied in the field of magnetic sensors, can solve problems such as difficulty in meeting actual needs, limited sensitivity and linear measurement range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

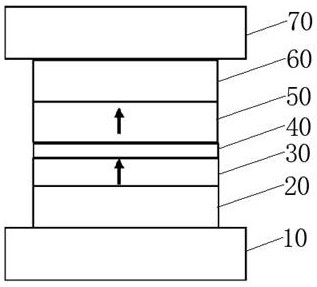

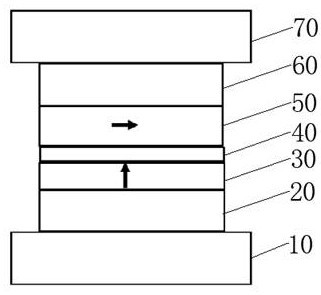

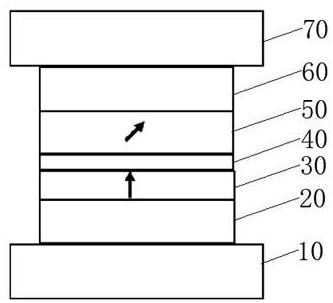

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036] In a magnetic tunnel junction (MTJ) based on tunnel magnetoresistance (TMR), the magnetization direction of the ferromagnetic thin layer can be switched independently under the control of an external magnetic field. If the polarization directions are parallel, electrons tunnel through the The possibility of the insulating layer will be greater, and the macroscopic performance is small resistance; if the polarization direction is antiparallel, the possibility of electron tunneling through the insulating layer is small, and the macroscopic performance is extremely large resistance. The magnetic tunnel junction can quickly switch between two resistance state...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com