Dynamic modeling and simulation method for nonlinear torsion bar spring independent suspension

A technology of dynamic modeling and torsion bar springs, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as large errors in theoretical analysis results and complex theoretical analysis processes, and achieve improved simulation efficiency and Effects of Simulation Accuracy, High Applicability and Operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

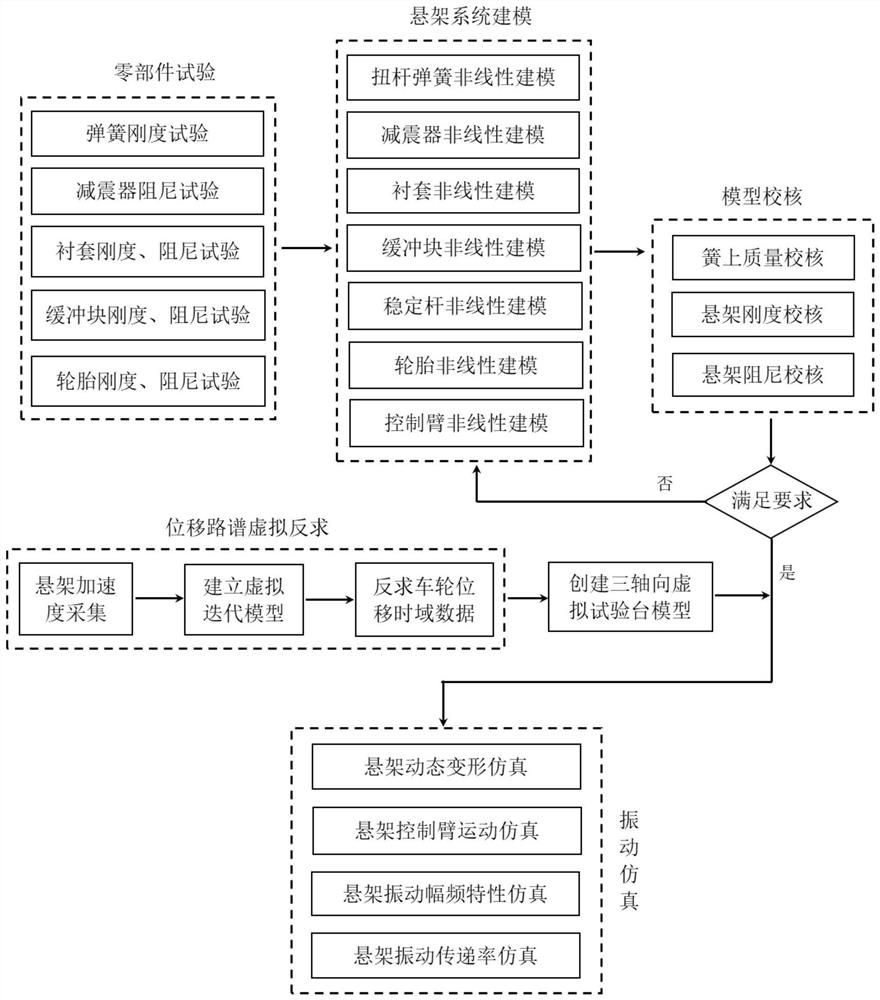

[0057] see figure 1 , this embodiment provides a nonlinear torsion bar spring independent suspension dynamics modeling and simulation method of the present invention, including the following steps:

[0058] Establish the dynamic model of the nonlinear torsion bar spring independent suspension.

[0059] The steps of component testing are:

[0060] Use test equipment to test the torsional stiffness of the torsion bar spring, the damping of the shock absorber, the stiffness and damping of the rubber bushing, and the stiffness of the buffer block;

[0061] Tire vertical stiffness, longitudinal stiffness, lateral stiffness, and torsional stiffness tests are carried out on a tire test bench;

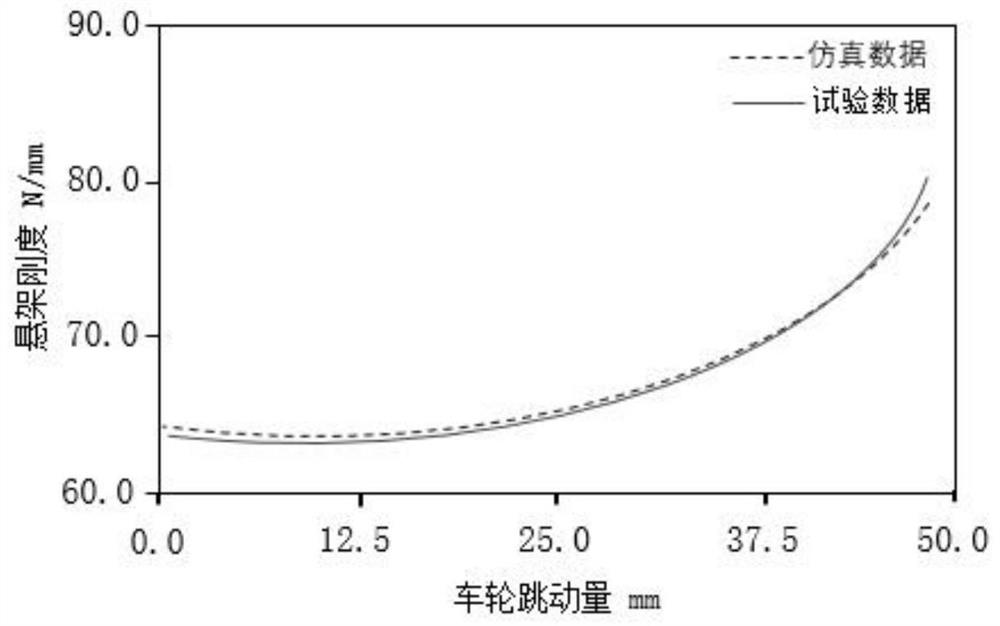

[0062] Use suspension K&C test bench to measure suspension stiffness and deflection, and combine LMS equipment to measure suspension damping;

[0063] Use the suspension K&C test bench to measure the wheelbase change;

[0064] The steps for modeling the suspension system are:

[0065] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com