Device for prolonging cycle life of high-voltage lithium cobalt oxide positive electrode material sagger

A cathode material and cycle life technology, which is applied in the field of devices for improving the cycle life of a high-voltage lithium cobalt oxide cathode material saggar, can solve the problems of poor cold and heat abrupt change performance, easy cracking and damage, cost, slag and peeling, and the like. The effect of reducing the holding force, improving the service cycle life and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

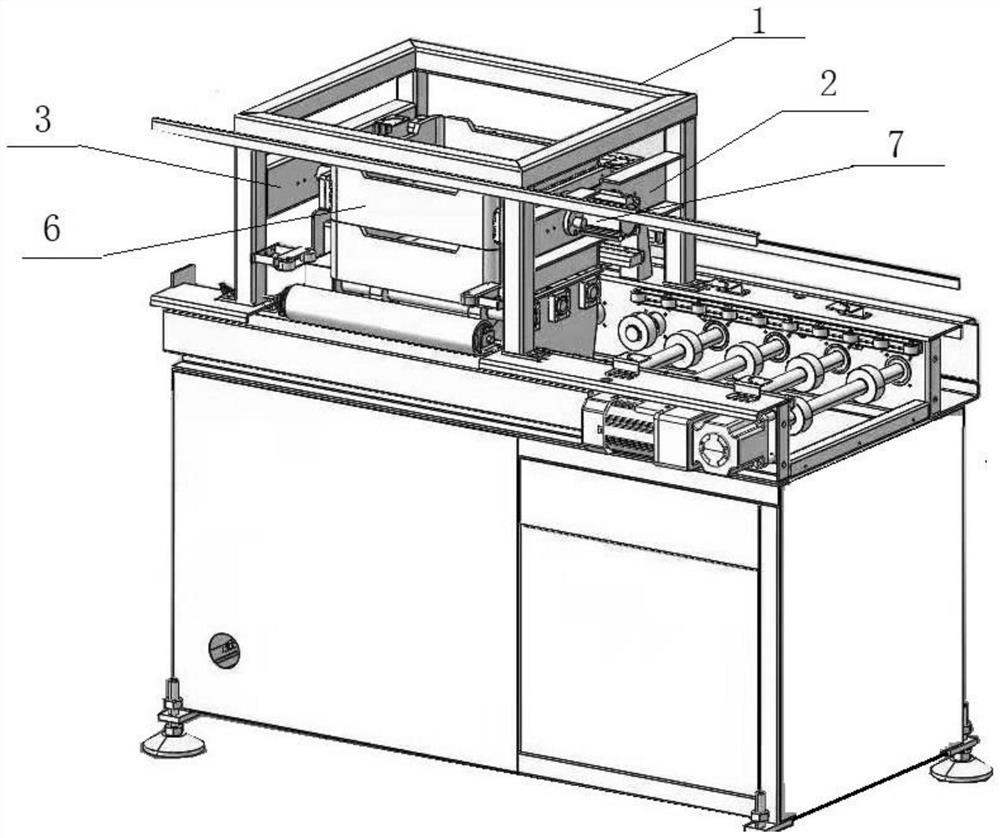

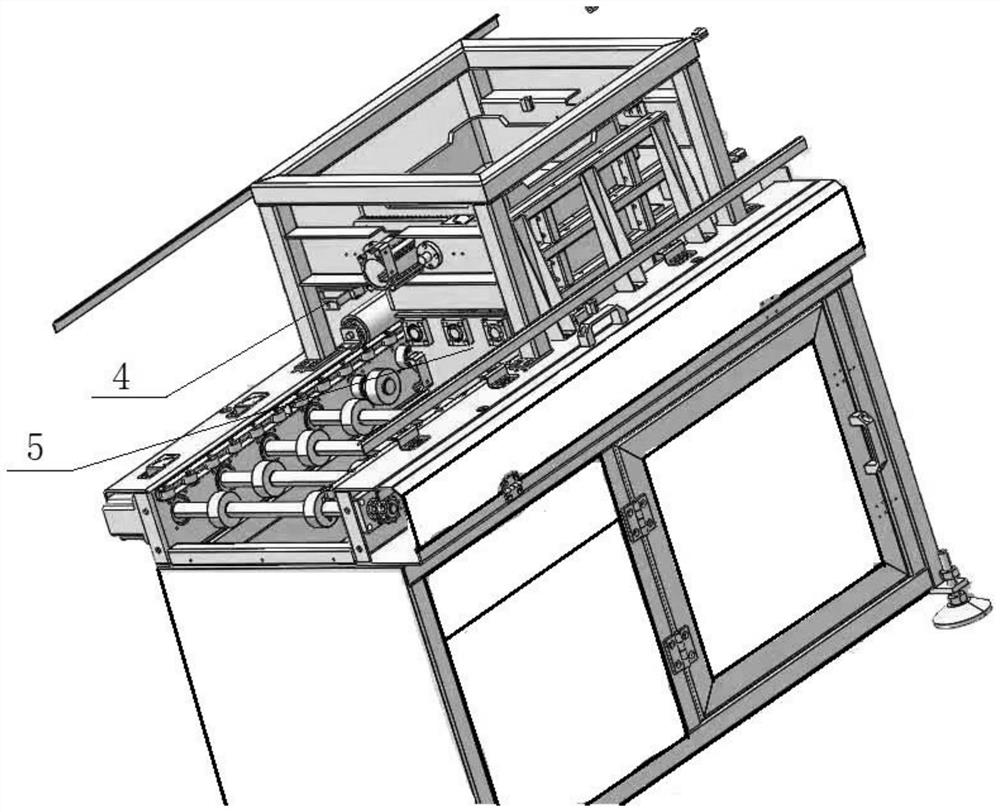

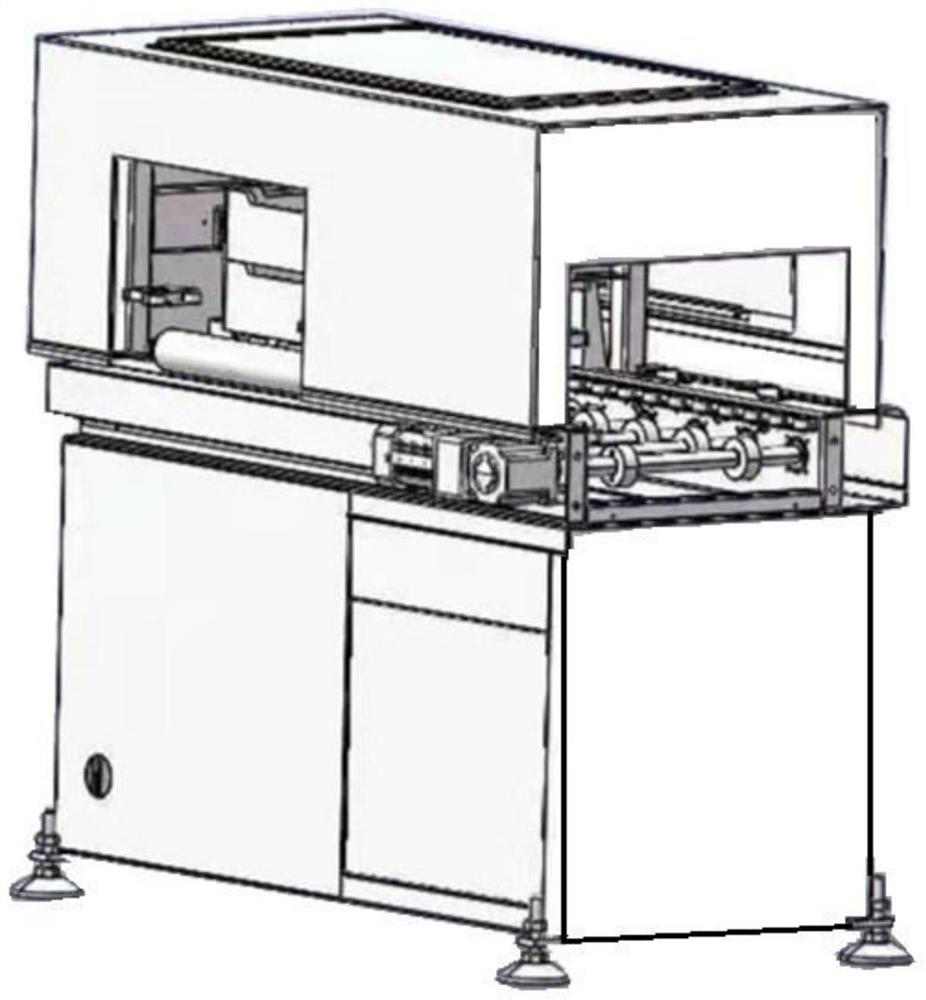

[0016] see Figure 1-5 , a device for improving the cycle life of a high-voltage lithium cobaltate positive electrode material sagger according to the present invention, comprising a stacking bowl mechanism housing 1, two clamping mechanisms, two polyurethane plates 3, a light sensor 4, a cylinder 5, For the sagger 6, two clamping mechanisms are installed inside the shell of the stacking bowl mechanism 1, and the two clamping mechanisms are located on both sides of the sagger 6; preferably, the two clamping mechanisms are located on opposite sides of the sagger 6. The clamping mechanism includes a motor, a clamping rod 7, and a clamping plate 2, the motor is connected to one end of the clamping rod 7, the other end of the clamping rod 7 is connected to one side of the clamping plate 2, and the other end of the clamping plate 2 A polyurethane board 3 is connected to the side, and two polyurethane boards 3 are close to both sides of the sagger 6; when the two clamping mechanisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com