Preparation method of urethral stent and urethral stent

A urethra and mixed solution technology, applied in the field of medical devices, can solve problems such as easy disintegration and fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

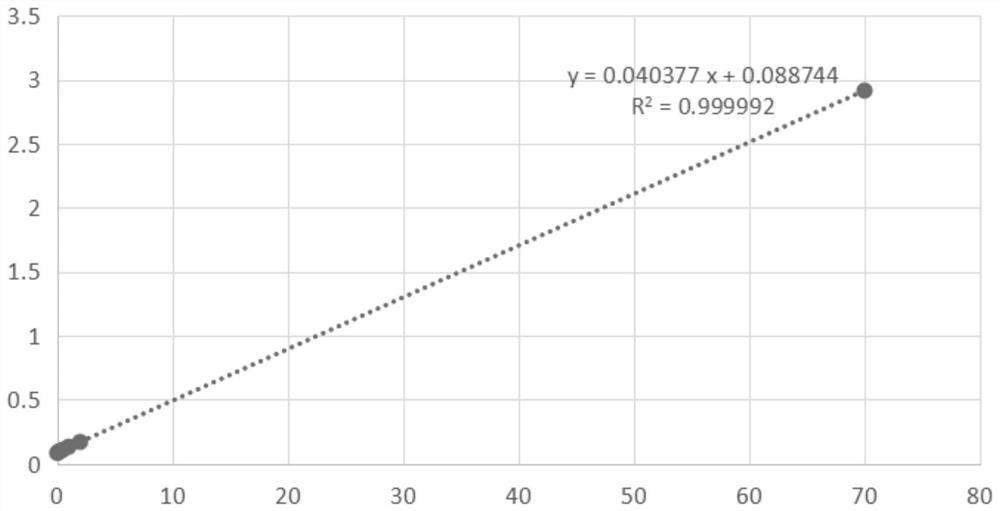

Image

Examples

preparation example Construction

[0034] It is well known that chitosan has good solubility only in acetic acid solution. However, PLLA is insoluble in acetic acid, so chitosan and PLLA do not have a common good solvent. The inventors tried to dissolve PLLA in chloroform and chitosan in acetic acid respectively, mix and stir, and pour the mold after 48 hours. However, because the volatility of chloroform is much greater than that of acetic acid, the resulting finished products failed to form a film. Although it has been reported that poly-L-lactide / chitosan membranes choose a solvent system consisting of acetic acid and dimethyl sulfoxide. Certain processing parameters, such as the concentrations of the component solutions and the composition ratios of the mixed solvent and the extraction solvent, were optimized by mainly considering whether a directly visible phase separation occurred during the processing, and finally the membrane was prepared. Alternatively, use solution precipitation and glutaraldehyde cr...

Embodiment 1

[0071] Step 1, dissolving lecithin and PLLA in chloroform to form the first mixed solution, the mass ratio of the lecithin and the PLLA is 5: 100, stirring the first mixed solution in a constant temperature water bath at 25°C for 48h, Then pour the suspension in a volume of 10ml / cm² into a glass or polytetrafluoroethylene mold to volatilize to form a film. The ambient temperature is 23°C and the relative humidity is 20%. After the film was dried, it was taken out and cut into long strips with a width of 4 mm. After the long strip is shaped into a ridge shape, it is wound into a spiral shape on a glass rod. Put it in a vacuum oven and dry at 37°C for 14 days to prepare the first PLLA scaffold;

[0072] Step 2. Wash the first PLLA stent prepared in step 1 three times in methanol aqueous solution (methanol / water = 1:1) within 25 minutes, dry it in vacuum at 30°C for 24 hours, and then place the dried first PLLA stent into a NaOH solution at a temperature of 58° C. for 30 minute...

Embodiment 2

[0079]Step 1, dissolving lecithin and PLLA in chloroform to form the first mixed solution, the mass ratio of the lecithin and the PLLA is 1: 100, stirring the first mixed solution in a constant temperature water bath at 40°C for 48h, Then pour the suspension in a volume of 10ml / cm² into a glass or polytetrafluoroethylene mold to volatilize to form a film. The ambient temperature is 23°C and the relative humidity is 20%. After the film was dried, it was taken out and cut into long strips with a width of 4 mm. After the long strip is shaped into a ridge shape, it is wound into a spiral shape on a glass rod. Put it in a vacuum oven and dry at 37°C for 14 days to prepare the first PLLA scaffold;

[0080] Step 2. Wash the first PLLA stent prepared in step 1 three times in methanol aqueous solution (methanol / water = 1:1) within 25 minutes, dry it in vacuum at 30°C for 24 hours, and then place the dried first PLLA stent into a KOH solution at a temperature of 58° C. for 30 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com