Method for preparing hollow fiber carbon membrane through direct wrapping heat treatment, and hollow fiber carbon membrane

A fiber carbon and hollow technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a hollow fiber carbon membrane by direct wrapping heat treatment, specifically as follows:

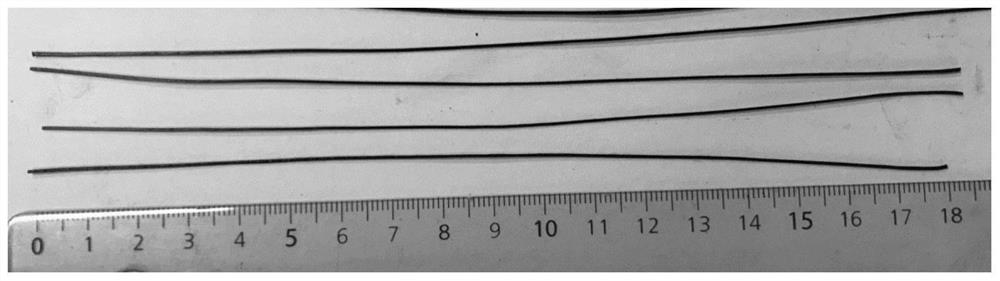

[0052] 1) Configure 18wt% PVDF spinning stock solution, prepare hollow fibers by spinning, and obtain PVDF hollow fibers with an inner / outer diameter of 0.7 / 1.3 mm and a membrane pore size of 0.05 μm, and then use a circulating blower for the PVDF hollow fibers at 80 ° C Dry for 24 hours to obtain the dried hollow fiber original membrane;

[0053] 2) Stretch and stretch the dried hollow fiber original membrane to 110% of the original length by the pull hook method, and then use ablative carbon paper with a thickness of about 0.5 mm to stretch the drawn and extended hollow fiber original membrane, Each fiber is wrapped at an interval of about 5mm (the so-called interval wrapping is to keep a certain distance between the hollow fibers), and then bundled with carbon fiber, wrapped with carbon paper, and fixed with a fixed-length frame to obtain a reinforced o...

Embodiment 2

[0062] A method for preparing a hollow fiber carbon membrane by direct wrapping heat treatment, specifically as follows:

[0063] 1) Dry the commercially available Shandong Jinhui PVDF hollow fiber with mixed hot air at 70°C for 24 hours to obtain the dried hollow fiber original membrane;

[0064] 2) Stretch and stretch the dried hollow fiber original membrane to 105% of the original length with an extensometer, then use a graphite felt with a thickness of about 0.8mm to stretch the hollow fiber original membrane, Each fiber is wrapped at an interval of about 6mm, then wrapped with thin metal (steel) wires, wrapped with carbon paper, and fixed with a non-deformed metal frame, to obtain a reinforced hollow fiber original membrane that is isolated from oxygen and wrapped and drawn;

[0065] 3) Put the strengthened isolated oxygen environment and the hollow fiber original membrane and its wrapper and the fixed frame at 105% magnification together in a high-temperature reaction fu...

Embodiment 3

[0073] A method of directly wrapping heat treatment to prepare hollow fiber carbon membranes. The commercially available polyimide PI hollow fibers are dried at 80° C. for 24 hours with a circulating blower to obtain the dried hollow fiber original membranes; the remaining steps are the same as in the examples 1. Obtain a hollow fiber carbon membrane.

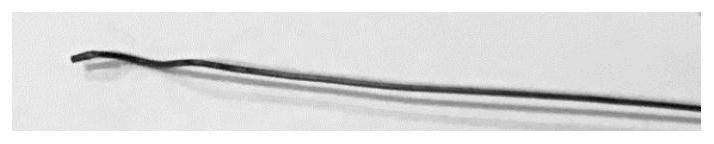

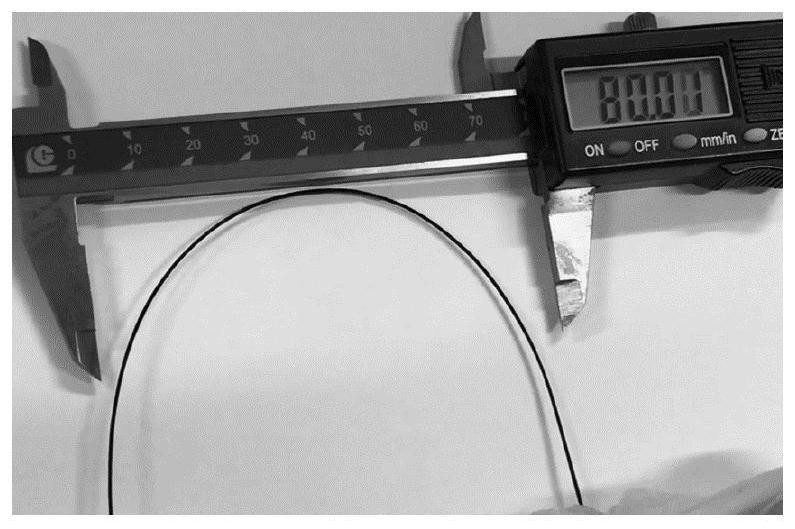

[0074] When the hollow fiber carbon membrane obtained in the example is bent at 180°, the hollow fiber carbon membrane is not broken or damaged, and the corresponding minimum cylinder diameter is ≦80mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com