High-load ZIF-67 membrane material and preparation method thereof

A ZIF-67, high-load technology, applied in the field of membrane materials, can solve the problems of slow adsorption speed, increased time and cost of uranium extraction, and uranium adsorption performance needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of high load ZIF-67 membrane material, comprises the following steps:

[0029] A) adopting the method of co-radiation grafting to graft maleic anhydride on the surface of the polymer base material to obtain the polymer base material of grafted maleic anhydride;

[0030] B) mixing metal salts, organic ligands, solvents and polymer base materials grafted with maleic anhydride, and reacting at 15-40°C to obtain high-loaded ZIF-67 membranes;

[0031] The metal salt is a cobalt salt;

[0032] The solvent includes methanol or water.

[0033] The present invention first adopts the co-radiation grafting method to graft maleic anhydride on the surface of the polymer base material. In some embodiments of the present invention, adopting the method for co-radiation grafting to graft maleic anhydride on the surface of the polymer base material includes:

[0034] In a sealed container, the tetrahydrofuran solution of maleic anhyd...

Embodiment 1

[0077] A 0.42 mm thick polypropylene (PP) non-woven fabric was ultrasonically cleaned in acetone, dried at 60°C and packed into an aluminum foil bag. Prepare a tetrahydrofuran solution of maleic anhydride with a mass fraction of 1.5 g / mL, then add the tetrahydrofuran solution of maleic anhydride and polypropylene non-woven fabric to the aluminum foil bag, so that the maleic anhydride solution is completely immersed in the polypropylene non-woven fabric, heat Plastic seal the aluminum foil bag, and put it into a radiation source (electron accelerator) to irradiate at room temperature, the radiation dose rate is 0.6kGy / h, and the radiation dose is 5kGy. The irradiated polypropylene non-woven fabric was ultrasonically cleaned with tetrahydrofuran and ethanol solvents in sequence, and dried at 60°C to obtain a polypropylene non-woven fabric grafted with maleic anhydride. The graft surface density of maleic anhydride was 26.70 nmol / cm 2 .

Embodiment 2

[0079] Will Co(NO 3 ) 2 ·6H 2 O (2.91g, 0.010mol) was dissolved in 50mL methanol to obtain the first solution; 2-methylimidazole (0.82g, 0.010mol) was dissolved in 200mL methanol to obtain the second solution; the first solution and the second After the solution was mixed, the polypropylene non-woven fabric (single area 50 * 200mm) of the grafted maleic anhydride prepared by 4 pieces of embodiment 1 2 ) into the mixed solution, the Co(NO 3 ) 2 ·6H 2 The ratio of the total molar amount of O and 2-methylimidazole to the surface area of the polypropylene nonwoven fabric grafted with maleic anhydride is 49.97 μmol / cm 2 , reacted in a reactor at 25°C and 1 atm for 24h. After the reaction, the non-woven fabric membrane was washed with methanol and dried at 60°C to obtain a high-loaded ZIF-67 membrane (HF-1).

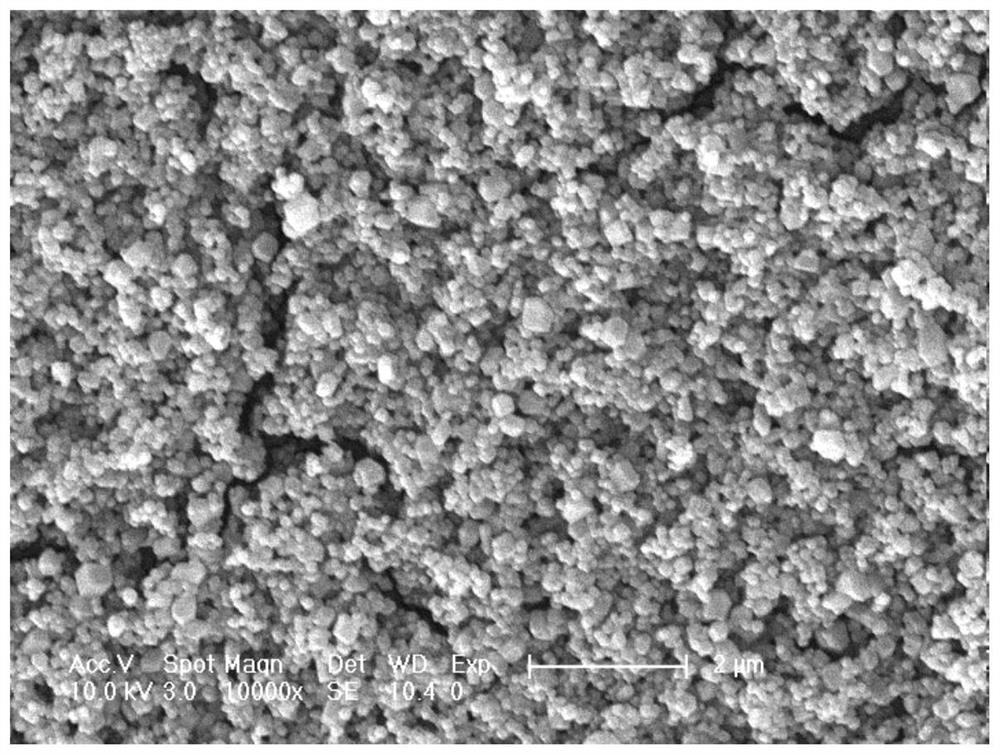

[0080] The high load ZIF-67 film (HF-1) that embodiment 2 obtains carries out scanning electron microscope analysis, and the result is as follows figure 1 shown. fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com