Continuous ZIF-8 film material and preparation method thereof

A technology of ZIF-8 and membrane materials, applied in the field of membrane materials, can solve the problems of uranium adsorption performance to be improved, increase the time and cost of uranium extraction, and slow adsorption speed, etc., achieve good application prospects, excellent uranium adsorption performance, The effect of easy recycling and post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a kind of preparation method of continuous ZIF-8 film material, comprises the following steps:

[0047] A) calculate and obtain the required maleic anhydride graft surface density of continuous ZIF-8 membrane material by formula (1);

[0048]

[0049] In formula (1), σ molar Maleic anhydride graft surface density required for continuous ZIF-8 membrane material, nmol / cm 2 ;

[0050] BET is the specific surface area of the polymer substrate material, m 2 / g;

[0051] ρ is the mass areal density of the polymer base material, g / cm 2 ;

[0052] A is Avogadro's constant;

[0053] a is the spacing between adjacent maleic anhydrides, nm;

[0054] B) according to the calculation result of step A), the method of co-radiation grafting is used to graft maleic anhydride on the surface of the polymer base material to obtain the polymer base material grafted with maleic anhydride;

[0055] C) metal salt, organic ligand, solvent and the macromolecule...

Embodiment 1

[0121] The surface maleic anhydride graft surface density is calculated as follows:

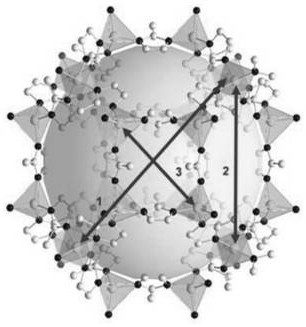

[0122] The crystal structure of ZIF-8 is as figure 1 as shown, figure 1 Crystal structure of ZIF-8. In the ZIF-8 lattice, the distance between adjacent metals includes three distances of 1, 2, and 3, and the length of distance 1 to 3 ranges from 0.85 to 1.9 nm. Since zinc ions need to coordinate with maleic anhydride, ZIF- 8. The nucleation points on the surface of the non-woven fabric make the continuous film grow further, so the distance a between the nucleation points is the distance between maleic anhydrides. When a is 0.85-1.9nm, a continuous film can be formed on the surface. In the present embodiment, the BET specific surface area of the non-woven fabric is 10.16m 2 / g, mass areal density ρ is 0.012g / cm 2 , Avogadro's constant A is 6.02×10 23 . According to the formula (1), calculate the maleic anhydride graft surface density σ molar 28~93.7nmol / cm 2 . Therefore, when the su...

Embodiment 2

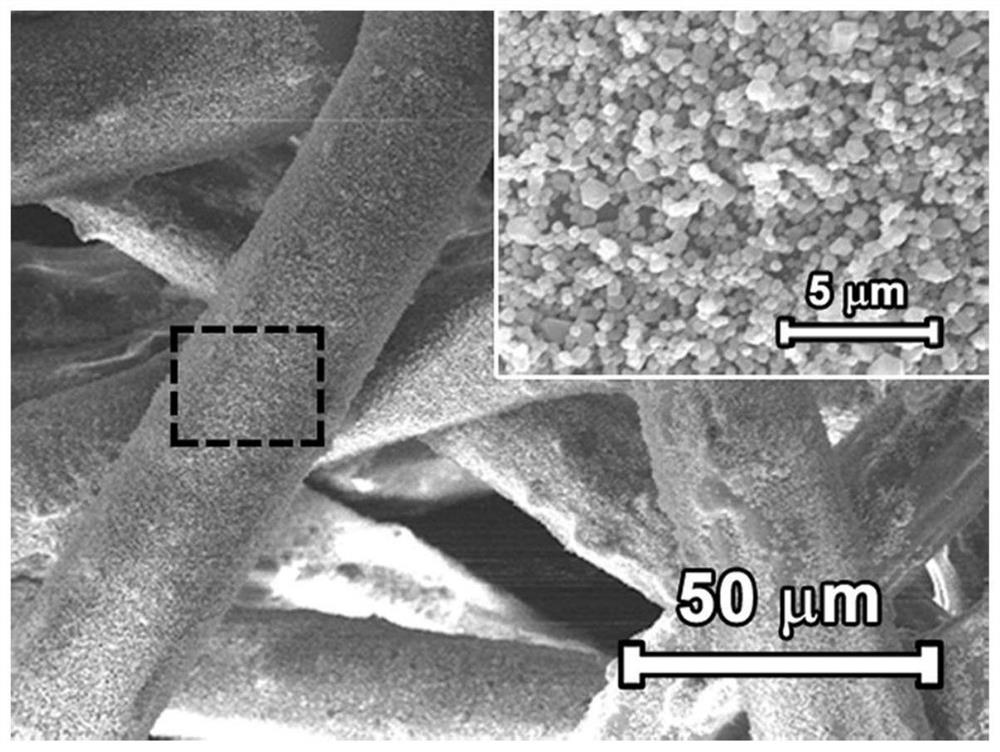

[0124] A 0.42 mm thick polypropylene (PP) non-woven fabric was ultrasonically cleaned in acetone, dried at 60°C and packed into an aluminum foil bag. Prepare a tetrahydrofuran solution of maleic anhydride with a mass fraction of 1.5 g / mL, then add the tetrahydrofuran solution of maleic anhydride and polypropylene non-woven fabric to the aluminum foil bag, so that the maleic anhydride solution is completely immersed in the polypropylene non-woven fabric, heat Plastic seal the aluminum foil bag, and put it into a radiation source (electron accelerator) to irradiate at room temperature, the radiation dose rate is 2.7kGy / h, and the radiation dose is 20kGy. The irradiated polypropylene non-woven fabric was ultrasonically cleaned with tetrahydrofuran and ethanol solvents in sequence, and dried at 60°C to obtain a polypropylene non-woven fabric grafted with maleic anhydride. The surface density of maleic anhydride grafted was 29.88 nmol / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com