High-precision ultrathin resin cutting blade and preparation method thereof

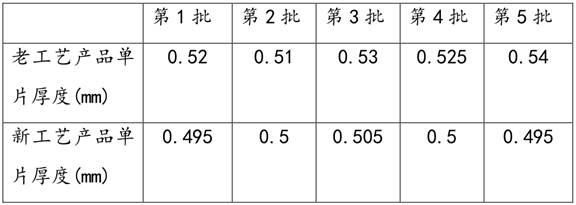

A high-precision cutting sheet technology, which is applied in the direction of flat products, other household appliances, household appliances, etc., can solve the problem of uneven thickness control of mixing materials, achieve the effect of high precision and uniform rebound, and solve the problem of thickness control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a high-precision ultra-thin resin cutting sheet of this embodiment includes the following steps:

[0025] S1. Heat silicon carbide micropowder, the main raw material that has passed strict inspection, to 50°C for standby;

[0026] S2. Heat the mixing pot to 50°C, pour the heated silicon carbide micropowder into the mixing pot and stir for 3 minutes, then allow it to be heated evenly;

[0027] S3. Add phenolic resin liquid binder for mixing. After heating the raw materials, the mixed material has good uniformity and strong consistency; among them, phenolic resin binder (phenolic resin binder) refers to an organic binder for refractory materials. . It is a resin obtained by polycondensation of a mixture of benzene (or cresol, or xylenol, or resorcinol) and formaldehyde (or furfural) under the action of a catalyst. Classified by product form, there are liquid phenolic resin binders (that is, phenolic resin liquid binders) and solid phenolic resin b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com