A kind of fluorite-based castable for aluminum industry and preparation method thereof

An industrial and castable technology, which is applied in the field of fluorite-based castables for aluminum industry and its preparation, can solve the problems of reduced service life of refractory materials, discount of anti-sticking aluminum effect, etc., and achieves extended service life, reduced porosity, excellent Effect of anti-corrosion characteristics of molten aluminum slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

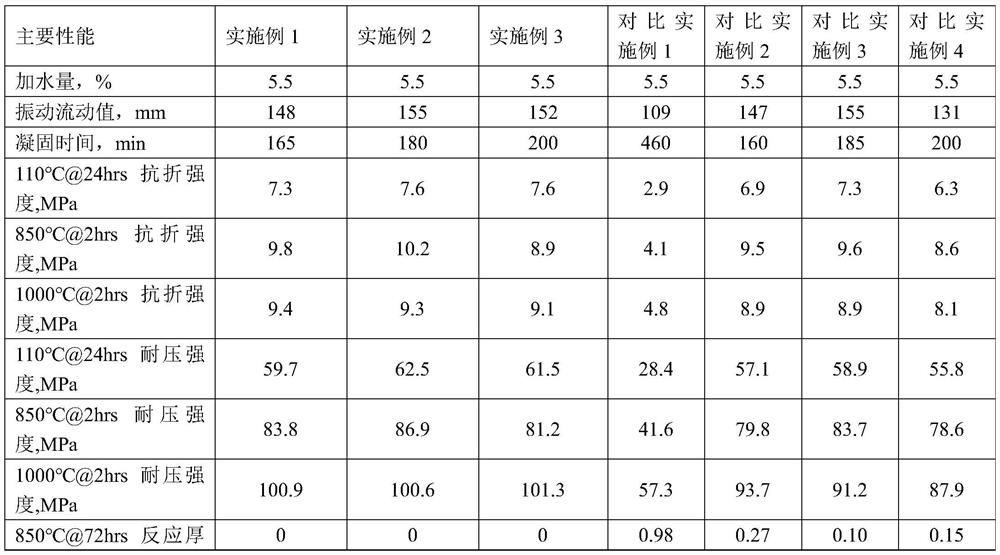

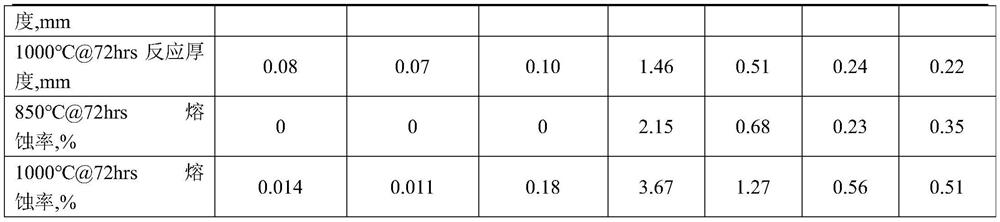

Examples

Embodiment 1

[0030] Embodiment 1: A kind of fluorite-based castable for aluminum industry and preparation method thereof

[0031] A fluorite-based castable for aluminum industry, calculated by weight percentage, comprising the following components: 71% fluorite, high-purity and low-sodium α-Al 2 O 3 Micronized powder 9%, aluminate cement 8%, SiC / Si 3 N 4 11%, water reducing agent 0.3%, explosion-proof fiber 0.1% and Al(OH) 3 0.6%.

[0032] Its preparation method comprises the following operation steps:

[0033] S1, sieve the fluorite to obtain fine fluorite with a particle size of 0.045 mm to 1 mm and a coarse fluorite with a particle size of 1 to 5 mm;

[0034] S2, the fluorite fine material, Al 2 O 3 , CaO, aluminate cement, SiC / Si 3 N 4 , water reducer and Al(OH) 3 Add to the mixer for premixing for 5min;

[0035] S3. Put the pre-mixed material in step S2, the explosion-proof fiber and the fluorite coarse material into a forced mixer for 10 minutes.

Embodiment 2

[0036] Example 2: A fluorite-based castable for aluminum industry, calculated by weight percentage, including the following components: 73% fluorite, high-purity and low-sodium α-Al 2 O 3 Micro powder 8%, aluminate cement 7%, SiC / Si 3 N 4 10%, water reducing agent 0.3%, explosion-proof fiber 0.1%, Al(OH) 3 0.8% and sodium aluminate 0.8%.

[0037] Its preparation method comprises the following operation steps:

[0038] S1, sieve the fluorite to obtain fine fluorite with a particle size of 0.045 mm to 1 mm and a coarse fluorite with a particle size of 1 to 5 mm;

[0039] S2, the fluorite fine material, Al 2 O 3 , CaO, aluminate cement, SiC / Si 3 N 4 , water reducer and Al(OH) 3 Add to the mixer for premixing for 5min;

[0040] S3. Put the pre-mixed material in step S2, the explosion-proof fiber and the fluorite coarse material into a forced mixer for 10 minutes.

Embodiment 3

[0041] Example 3: A fluorite-based castable for aluminum industry, calculated by weight percentage, including the following components: 78% fluorite, high-purity and low-sodium α-Al 2 O 3 Micro powder 7%, aluminate cement 5%, SiC / Si 3 N 4 9%, water reducing agent 0.3%, explosion-proof fiber 0.1%, Al(OH) 3 0.6%.

[0042] Its preparation method comprises the following operation steps:

[0043] S1, sieve the fluorite to obtain fine fluorite with a particle size of 0.045 mm to 1 mm and a coarse fluorite with a particle size of 1 to 5 mm;

[0044] S2, the SiC / Si 3 N 4 and Al 2 O 3 As for the uniform ball milling in the star ball mill to obtain SiC / Si 3 N 4 and Al 2 O 3 The mixture is taken out and dried with fluorite fines, CaO, aluminate cement, water reducer and Al(OH) 3 Add to the mixer for premixing for 5min;

[0045] S3. Put the pre-mixed material in step S2, the explosion-proof fiber and the fluorite coarse material into a forced mixer for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com