Stationary blade distortion-resistant axial flow compressor and axial flow compressor stationary blade distortion-resistant method

An axial flow compressor, anti-distortion technology, applied in the direction of machine/engine, mechanical equipment, non-variable-capacity pump, etc., can solve the problems of destroying the axisymmetric flow of the airflow, increasing the static blade load, and reducing the compressor stability margin. , to achieve the effect of improving aerodynamic performance and stability margin, suppressing resonance and damage, and ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

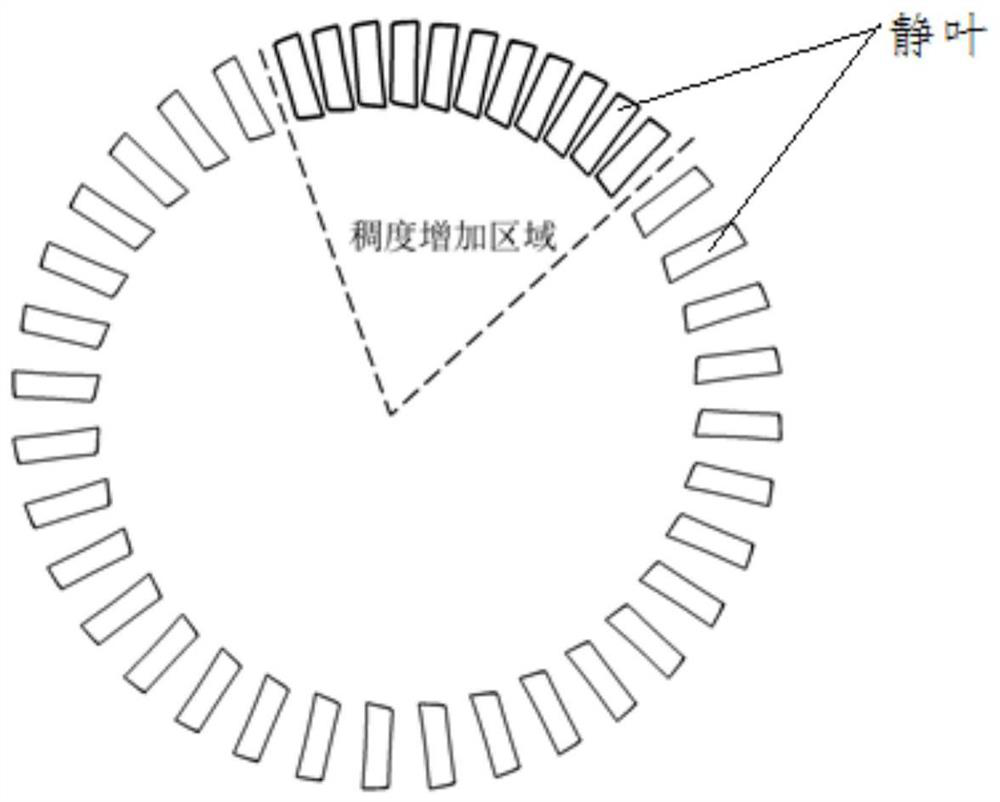

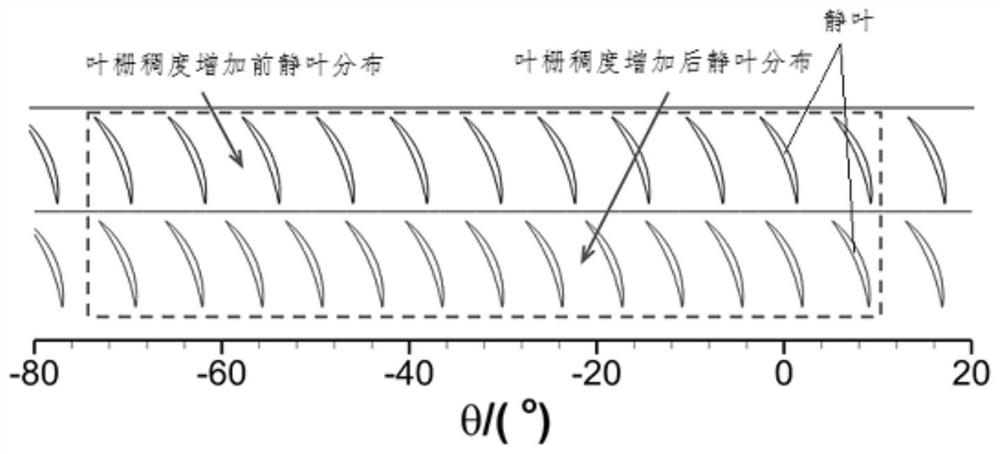

[0055] Embodiment 1, simply increasing the number of stator blades in the distortion zone. Specifically: the chord length of the stator blades in the distortion area remains the same as the original chord length, and the number of stator blades in the distortion area is increased so that the number of stator blades in the distortion area is greater than the original number of stator blades in this area. The principle is that the number of stator blades in the distortion zone is simply increased. At this time, the number of blades in the distortion zone of the compressor stator blades is greater than the original number, the pitch of the stator blades in the distortion zone is smaller than that in the non-distortion zone, and the blade chord length remains The original chord length remains unchanged. According to the consistency formula, at this time, the consistency of the distortion area is greater than the original cascade consistency. Since the cascade consistency in the non...

Embodiment 2

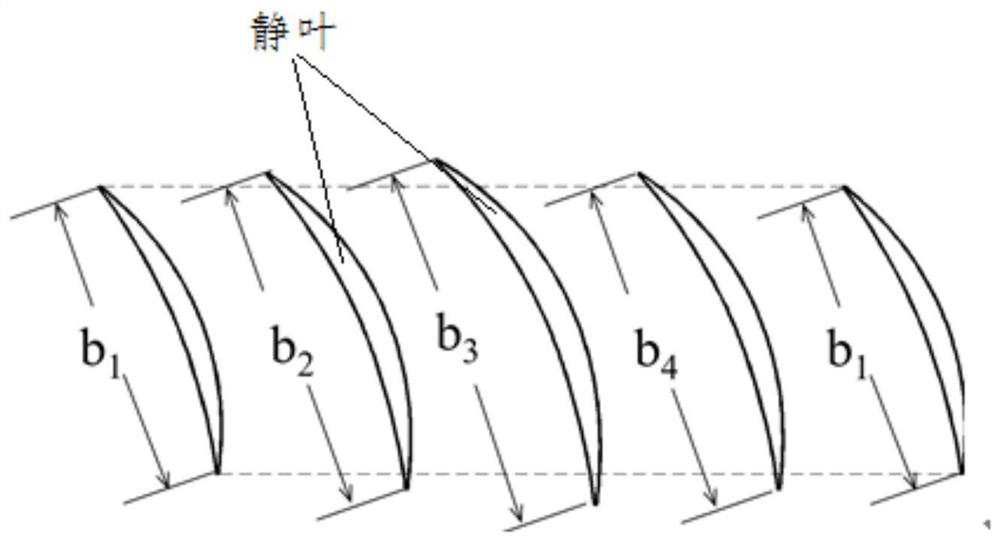

[0056] Embodiment 2 simply increases the chord length of the stator blade in the distortion zone. Specifically: the number of stator blades in the distortion zone remains the same as the original number in the zone, and the chord length of the stator blades in the distortion zone is increased. Since the chord length of the stator blade in the distortion area of the compressor stator blade is greater than the original chord length, and the number of blades remains the same as the original number, that is, the blade pitch remains unchanged, it can be known from the consistency formula that the cascade consistency in the distortion area is greater than the original consistency at this time. The consistency of the vane in the distortion area remains unchanged from the original consistency, so the cascade consistency in the distorted area of the stationary vane is greater than that in the non-distortion area. Such as image 3 As shown, the specific value of the chord length b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com