Method for controlling converter tilting system by using S120 frequency converter

A converter tilting system and frequency converter control technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc., can solve the problem of increased labor costs, slow data transmission speed, and system reliability. The problem is not high, to achieve the effect of improving economic benefits and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments

[0021] The method of using S120 frequency converter to control the converter tilting system provided by the present invention is applicable to the converter tilting system including four S120 frequency converters, and there is one as the master frequency converter and the other three as slave frequency converters, and another slave frequency converter is selected As a standby main inverter, each inverter includes a control unit, including the following steps:

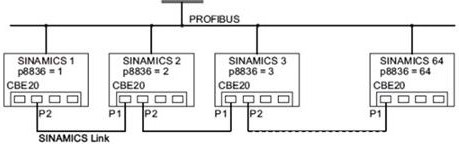

[0022] First, install CBE20 communication boards on the CU320-2DP of the four inverters in the converter tilting system, and define stations 1-4 for them respectively, and connect them through network cables. The network cable jumps from P2 port of station 1 to station 2 P1 port of the station, and so on, such as figure 1 shown.

[0023]The second step is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com