Tactile sensor

A tactile sensor and contact surface technology, applied in instruments, force/torque/power measuring instruments, measuring devices, etc., can solve the problems of easy wear of sensors, vibration of small surfaces, large sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

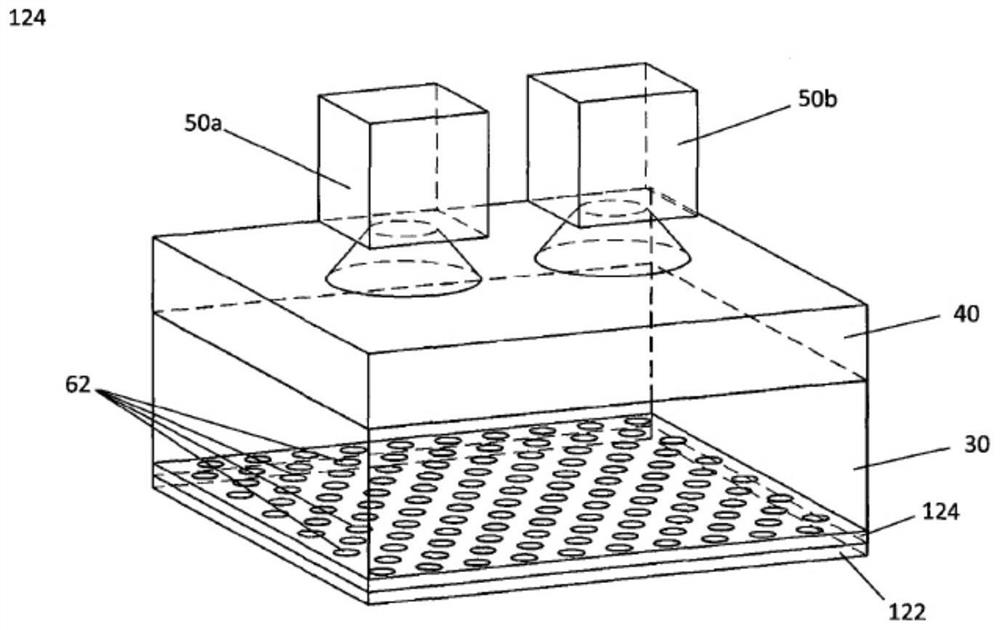

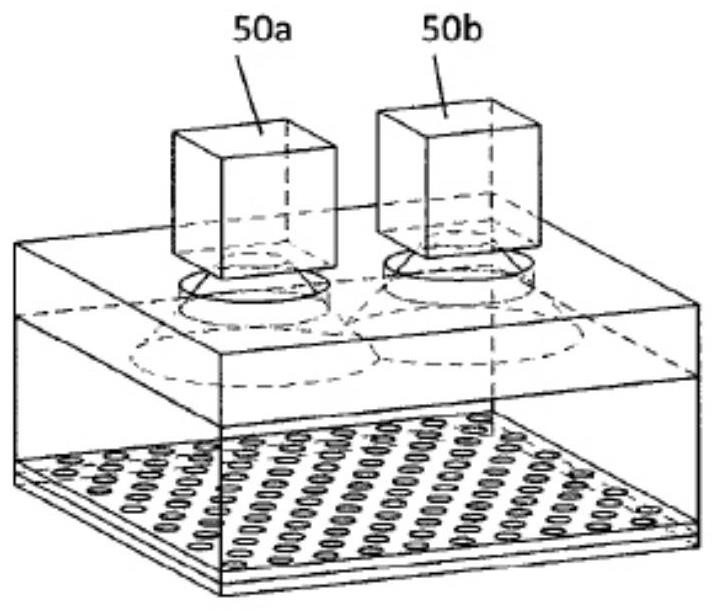

[0062] Embodiments of the present invention and modifications thereof will now be described in detail with reference to the accompanying drawings.

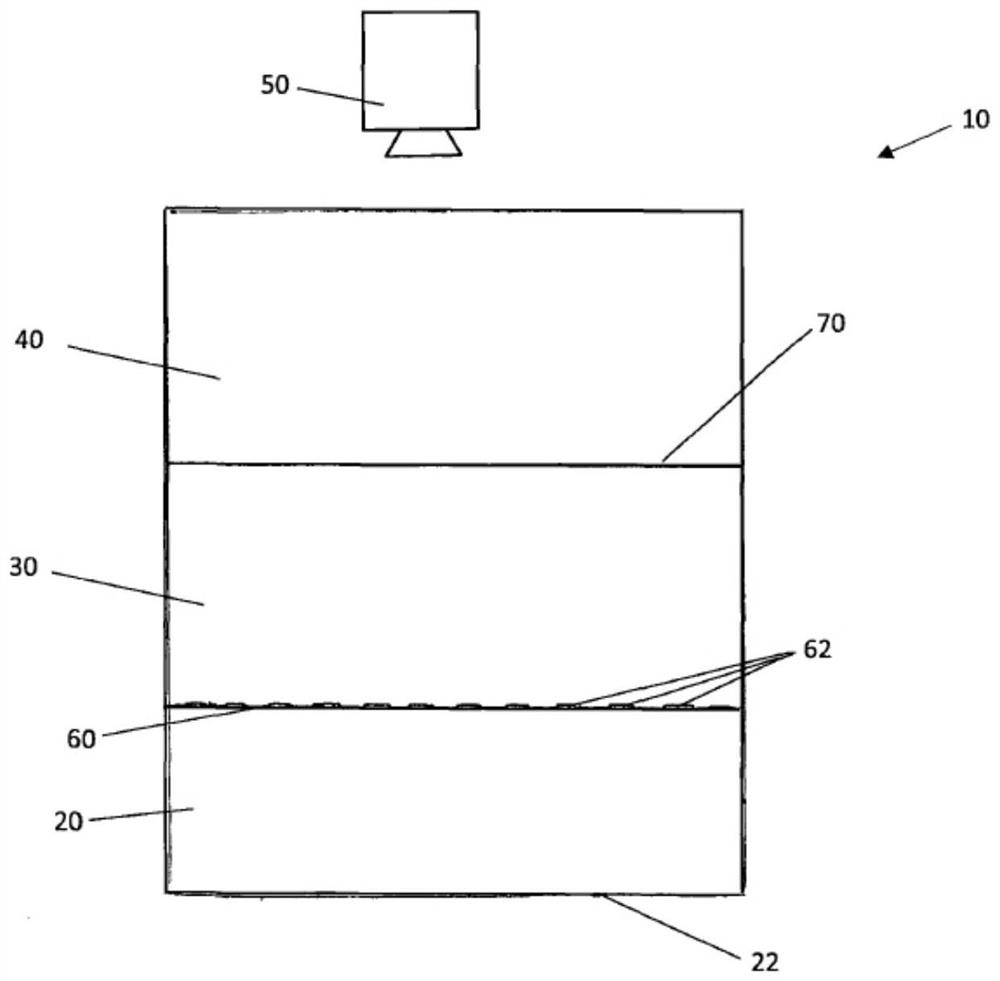

[0063] sensor structure

[0064] figure 1 A simplified schematic cross-sectional view of the general structure of an embodiment of a tactile sensor of the present invention is shown to illustrate principles of construction and operation. The tactile sensor 10 has three main parts: a flexible opaque outer layer 20 , a flexible transparent central layer 30 , a substantially rigid transparent inner layer 40 and a camera 50 .

[0065] The flexible opaque outer layer 20 is made of an opaque elastic material, and the flexible transparent layer 30 is made of a transparent elastic material. The two layers are in contact with each other at the first joint surface 60 .

[0066] The opaque layer 20 is sufficiently opaque that changes in external lighting cannot be detected by the camera. That is, a change in incident light on the outer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com