Black tea and processing method thereof

A processing method and technology for black tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of low rolling and breaking rate, high tea breaking rate, poor appearance quality of tea leaves, etc., achieve complete enzymatic oxidation reaction, promote nutrient transformation, and improve appearance quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

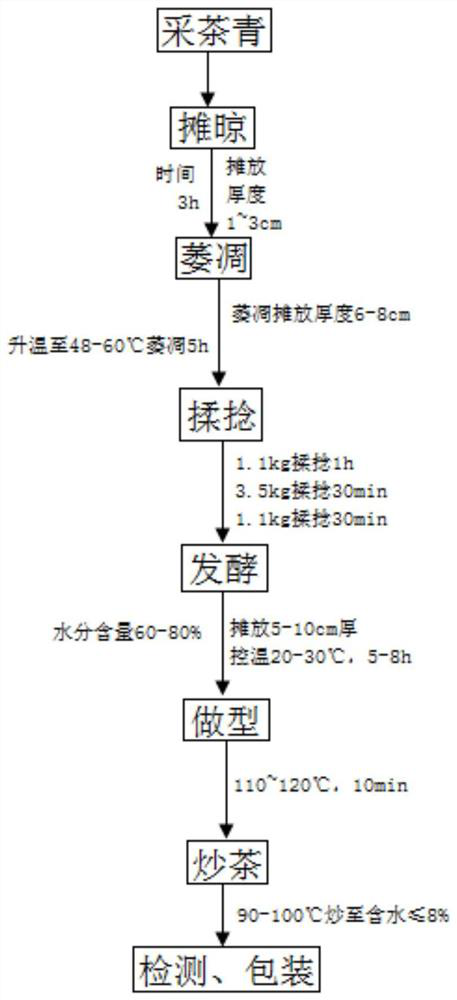

Method used

Image

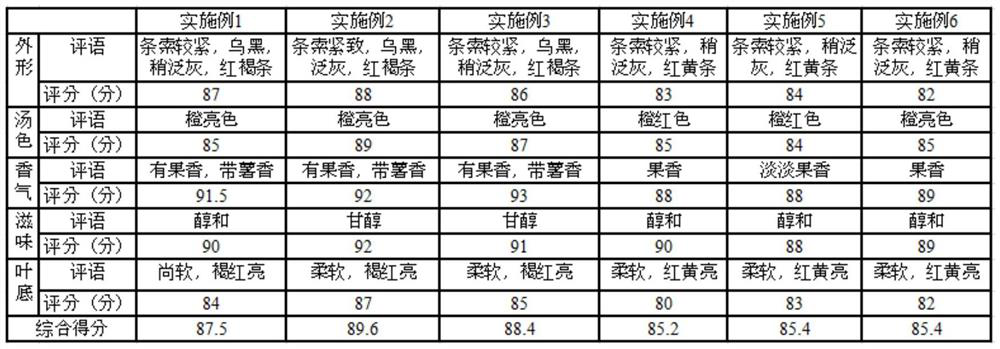

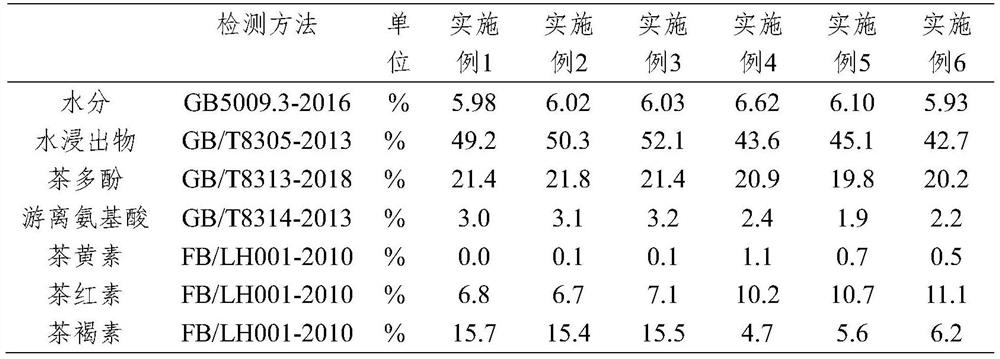

Examples

Embodiment 1

[0030] Pick one bud and one leaf tea green, spread the tea green on bamboo rafts with a thickness of 1cm, and let it dry for 3 hours at room temperature; then put it into the withering tank, adjust the spreading thickness to 6cm, raise the temperature to 48°C, and wither for 5 hours ;Place it in a kneading machine, first knead with 1.1kg for 1 hour, then use 3.5kg for 30 minutes, and then 1.1kg for 30 minutes; then send it to a fermentation room with a relative humidity of 80% for fermentation. The thickness is 5cm, the temperature is controlled at 20°C for 5 hours of fermentation, and the moisture content is adjusted to about 60%. Put it into the tea frying pot, first shape it at 110°C for 30 minutes, and then fry the tea at 90°C until the moisture content is ≤8 %, that is, black tea.

Embodiment 2

[0032] Pick one-bud and two-leaf tea greens, spread the tea greens on bamboo rafts with a thickness of 3 cm, and let them dry for 3 hours at room temperature; then put them into the withering tank, adjust the spreading thickness to 8 cm, raise the temperature to 60°C, and wither for 5 hours ;Place it in a kneading machine, first knead with 1.1kg for 1 hour, then use 3.5kg for 30 minutes, and then 1.1kg for 30 minutes; then send it to a fermentation room with a relative humidity of 80% for fermentation. The thickness is 10cm, the temperature is controlled at 30°C for 8 hours of fermentation, and the moisture content is adjusted to about 80%, and it is sent into the tea frying pot. %, that is, black tea.

Embodiment 3

[0034] Pick one-bud-one-leaf and one-bud-two-leaf tea greens, spread the tea greens on bamboo rafts with a thickness of 2cm, and let them dry for 3 hours at room temperature; then put them into the withering tank, adjust the spreading thickness to 7cm, and heat up to 50°C, wither for 5 hours; put it in a kneading machine, first knead with 1.1kg for 1 hour, then use 3.5kg for 30 minutes, and then use 1.1kg for 30 minutes; then send it to a fermentation room with a relative humidity of 80%. Let it ferment, spread it to a thickness of 8cm, control the temperature at 25°C for 7 hours, and adjust the moisture content to about 70%, put it into the frying tea pot, first shape it at 120°C for 35 minutes, and then fry the tea at 90°C When the water content is less than or equal to 8%, black tea is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com