Method for improving stability of fish soup flavor material

A flavoring and stability technology, which is applied in the field of processing to improve the stability of fish soup flavoring, can solve the problems of restricting the commercial and industrial production of fish soup flavoring, difficulty in controlling the degree of protein enzymatic hydrolysis, and the decline in flavor quality of soup, etc. Achieve good market prospects, improve appearance quality and acceptability, and have the effect of milky white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) After cleaning the fish bones and minced meat of cultured puffer fish (non-toxic) leftovers, they are broken into fragments and bone sludge with sizes of 0.3, 1, 3, and 5 cm respectively.

[0043] Preheat the pot in the 1400w induction cooker heating mode for 1 minute, add cooking oil to the pot, and when the oil temperature rises to about 140°C, put the broken fish bones and minced meat into the pot and fry for 2 minutes on both sides.

[0044] (2) Add water for boiling, the mass ratio of leftovers (fish bones, minced meat) to water is 1:6, and the boiling time is 60 minutes.

[0045] (3) After the fish soup is cooled to room temperature, filter it with a 100-mesh filter and homogenize it at 30 MPa and 60°C for 5 minutes; detect the collagen content in the fish soup test, and perform sensory evaluation.

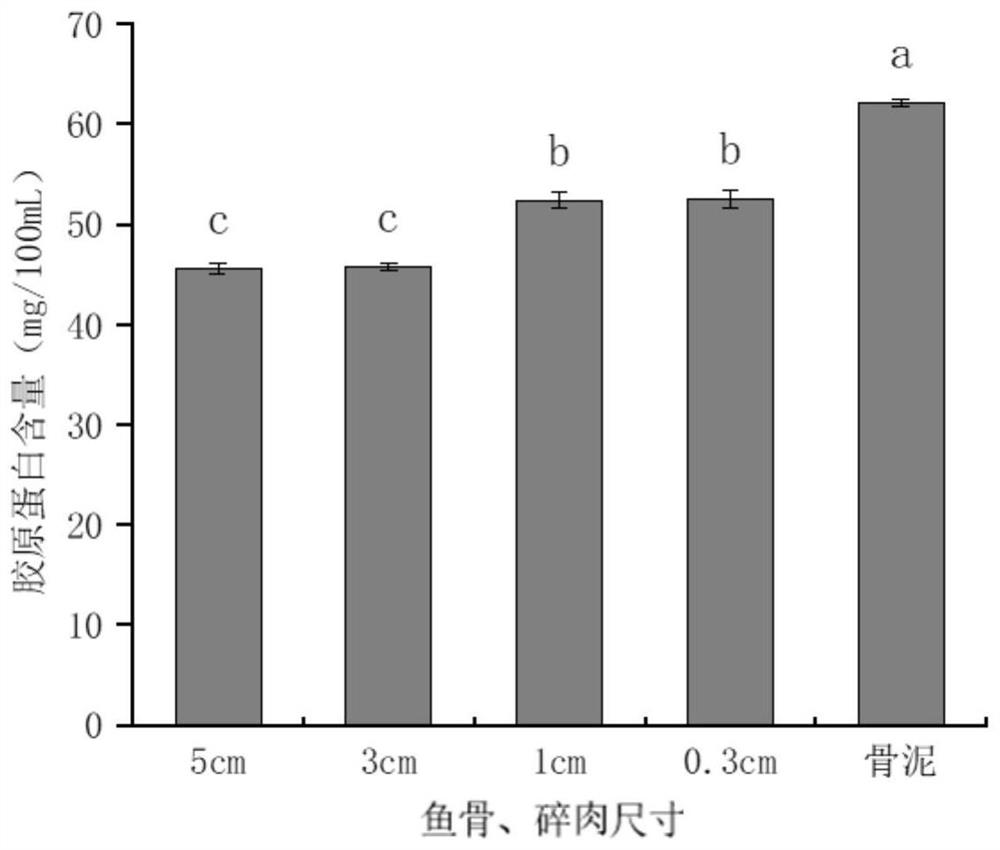

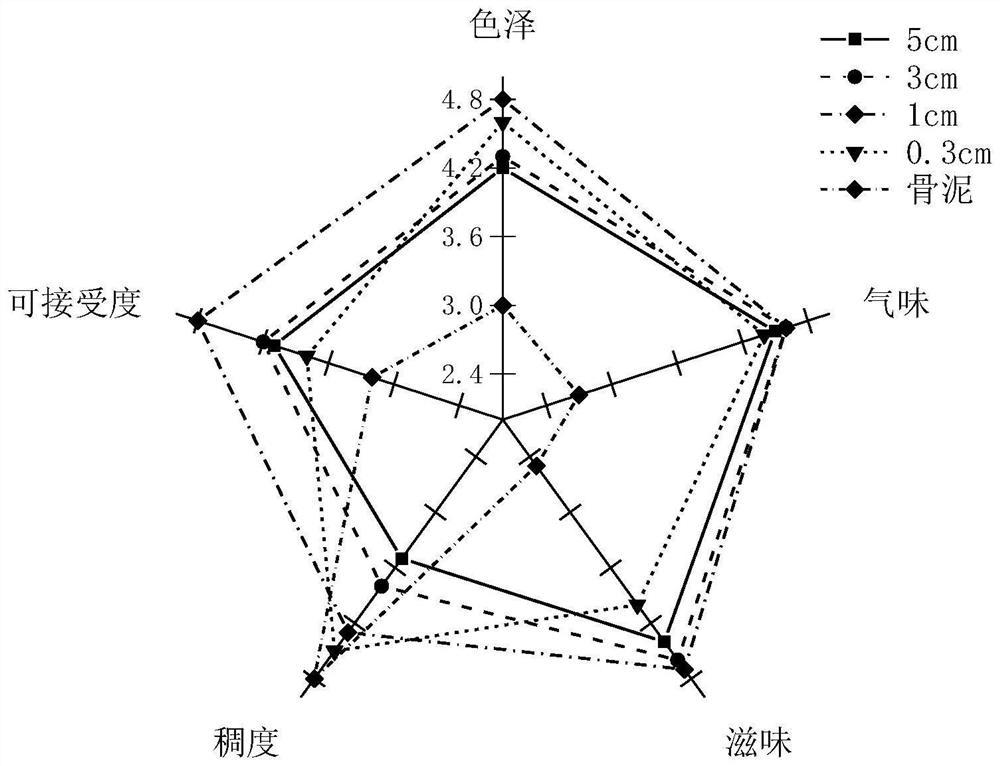

[0046] The effects of different sizes of fish bones and minced meat on the collagen content of fish soup are as follows: figure 1 As shown, the impact on the sen...

Embodiment 2

[0049] (1) After cleaning the fish bones and minced meat of cultured puffer fish (non-toxic) leftovers, break them into pieces with a size of 1 cm.

[0050] Preheat the pot in the 1400w induction cooker heating mode for 1 minute, add cooking oil to the pot, and when the oil temperature rises to about 140°C, put the broken fish bones and minced meat into the pot and fry for 2 minutes on both sides.

[0051] (2) Add water to cook, the mass ratio of leftovers (fish bones, minced meat) to water is 1:4, 1:5, 1:6, 1:7 and 1:8 respectively, and the cooking time is 60min.

[0052] (3) After the fish soup is cooled to room temperature, filter it with a 100-mesh filter and homogenize it at 30 MPa and 60°C for 5 minutes; detect the collagen content in the fish soup, and perform sensory evaluation.

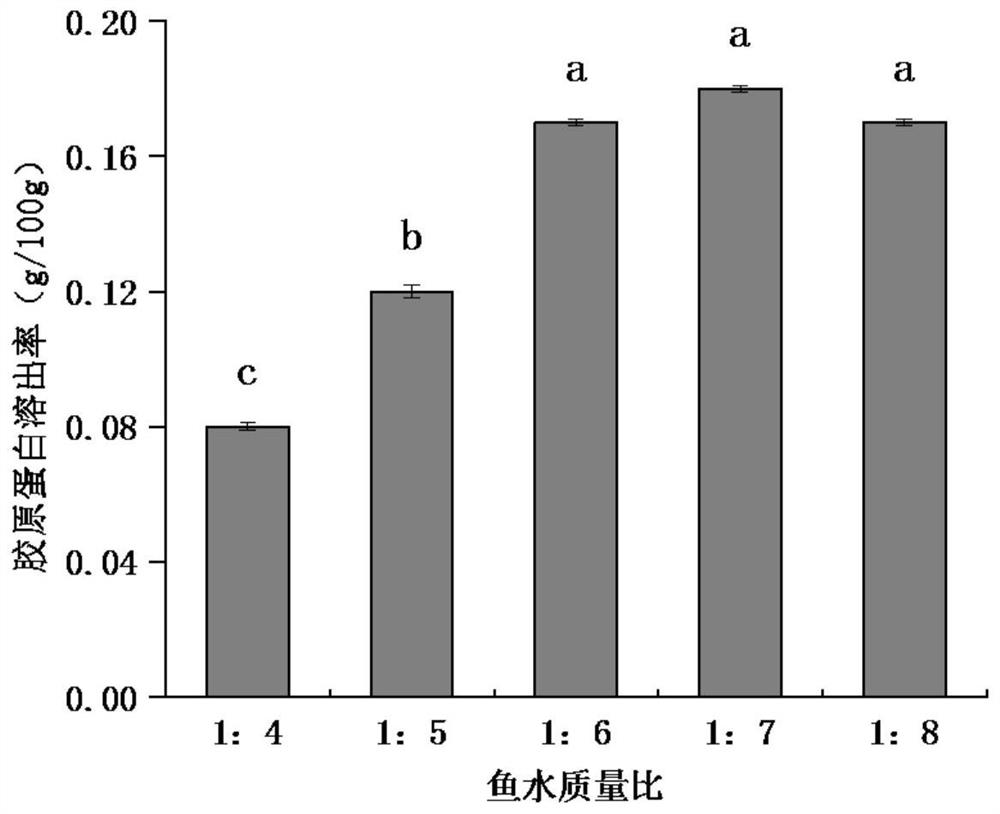

[0053] The effects of different fish-water ratios on the collagen content of fish soup are as follows: image 3 As shown, the impact on the sensory score of fish soup is as Figure 4 shown. ...

Embodiment 3

[0056] (1) After cleaning the fish bones and minced meat of cultured puffer fish (non-toxic) leftovers, break them into pieces with a size of 1 cm.

[0057] Preheat the pot in the 1400w induction cooker heating mode for 1 minute, add cooking oil to the pot, and when the oil temperature rises to about 140°C, put the broken fish bones and minced meat into the pot and fry for 2 minutes on both sides.

[0058] (2) Add water for boiling, the mass ratio of leftovers (fish bones, minced meat) to water is 1:6, and the cooking time is 30, 45, 60, 75 and 90 minutes respectively.

[0059] (3) After the fish soup is cooled to room temperature, filter it with a 100-mesh filter and homogenize it at 30 MPa and 60°C for 5 minutes; detect the collagen content in the fish soup, and perform sensory evaluation.

[0060] The effects of different cooking times on the collagen content of fish soup are as follows: Figure 5 As shown, the impact on the sensory score of fish soup is as Figure 6 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com