Method for improving polishing quality of stainless steel surface

A surface polishing, stainless steel technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding machine parts, etc., can solve the problem that the surface of the product cannot meet the 8K standard of stainless steel polished plate, and the polishing quality of stainless steel cold-rolled BA plate is poor. , insufficient surface gloss, etc., to improve the polishing quality, reduce the cost of unqualified products, and eliminate the effect of polishing printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] ①Prepare a 430 stainless steel plate with a surface grade of BA and a thickness*width*length specification of 0.5mm*1219mm*2000mm.

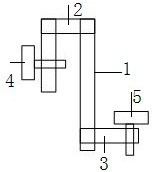

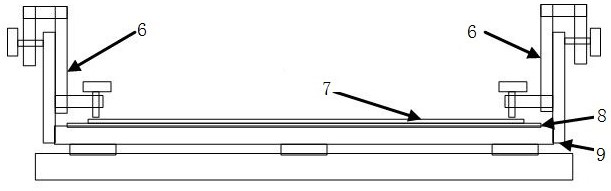

[0051] 2. Use the workpiece fixing device in the method of the present invention to fix the steel plate on the rubber pad with a thickness of 1.5 cm, and attach the steel plate tightly to the frame.

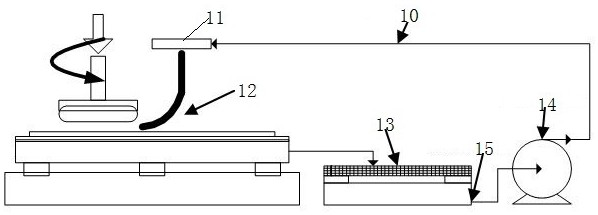

[0052] ③The polishing pressure is set to 3.3kpai, the rotational speed of the throwing head is set to 25-27HZ, the horizontal moving speed of the frame is set to 78HZ, and the vertical moving speed of the frame is set to 43HZ.

[0053] ④ The configuration ratio is 1.5 kg of alumina powder, 8 L of 64% nitric acid, and 400 L of water polishing solution.

[0054] ⑤ After starting the polishing liquid circulation device in the invention and circulating for 8.5 minutes, use a sponge with a diameter of 240mm, a thickness of 5cm, and medium hardness, and wrap the sponge with a thickness of 2mm very soft wool felt for combined polishing.

[0055] Th...

Embodiment 2

[0062] ①Prepare a 304 stainless steel plate with a surface grade of BA and a thickness*width*length specification of 0.6mm*1219mm*2000mm.

[0063] 2. Use the workpiece fixing device in the method of the present invention to fix the steel plate on the rubber pad with a thickness of 1.5 cm, and attach the steel plate tightly to the frame.

[0064] ③The polishing pressure is set to 3.5kpai, the rotational speed of the throwing head is set to 26-29HZ, the horizontal moving speed of the frame is set to 79HZ, and the vertical moving speed of the frame is set to 43HZ.

[0065] ④ The configuration ratio is 1.5 kg of alumina powder, 8 L of 64% nitric acid, and 400 L of water polishing solution.

[0066] ⑤ After starting the polishing liquid circulation device in the invention and circulating for 9.5 minutes, use a sponge with a diameter of 240mm, a thickness of 5cm, and medium hardness, and wrap the sponge with a thickness of 2mm very soft wool felt for combined polishing.

[0067] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com