Method for cooling and discharging high-temperature tail gas of aircraft APU in ultralow-temperature environment in laboratory

A kind of exhaust emission and laboratory technology, applied in the direction of aircraft component testing, etc., can solve the problems of damage temperature, pressure environment, safety threat of aircraft test personnel, etc., and achieve the effect of ensuring heating temperature, facilitating promotion and use, and preventing short-circuit burnout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

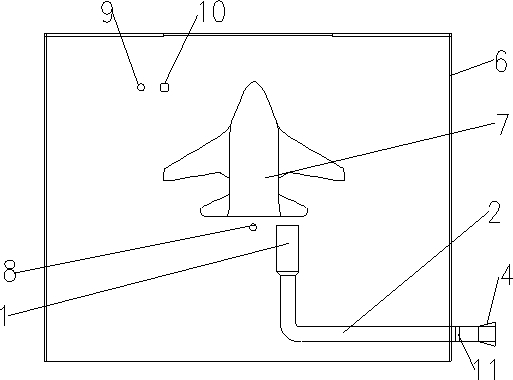

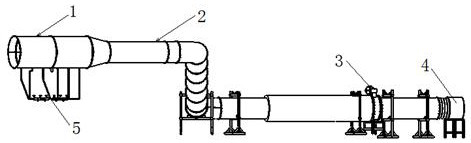

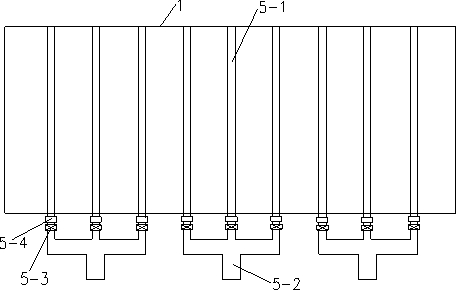

[0049] Such as Figure 1 to Figure 6 As shown, the aircraft APU high-temperature tail gas cooling and discharging method under the ultra-low temperature environment in the laboratory of the present invention uses the aircraft APU exhaust system in the laboratory to discharge and cool the aircraft APU exhaust. The aircraft APU exhaust system in the laboratory includes for The laboratory 6 containing the aircraft 7 and the aircraft APU exhaust equipment that outputs the aircraft APU exhaust to the outside, the aircraft APU exhaust equipment includes an initial adjustment pipeline 1, a drainage pipeline 2, a butterfly valve 3 and a fan 4 connected in sequence, and the initial adjustment pipeline 1 is provided with a spray cooling device 5, and the spray cooling device 5 includes a plurality of spray cooling mechanisms uniformly arranged along the length direction of the initial adjustment pipeline 1, and the spray cooling mechanism includes a water supply pipe arranged outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com