Blast furnace slag flushing device and method

A blast furnace slag flushing and water slag technology, applied in the field of blast furnace smelting, can solve the problems of affecting the filtering effect, corroded cover plate, heavy workload, etc., and achieve the effect of prolonging the service life, avoiding corrosion, and reducing the number of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

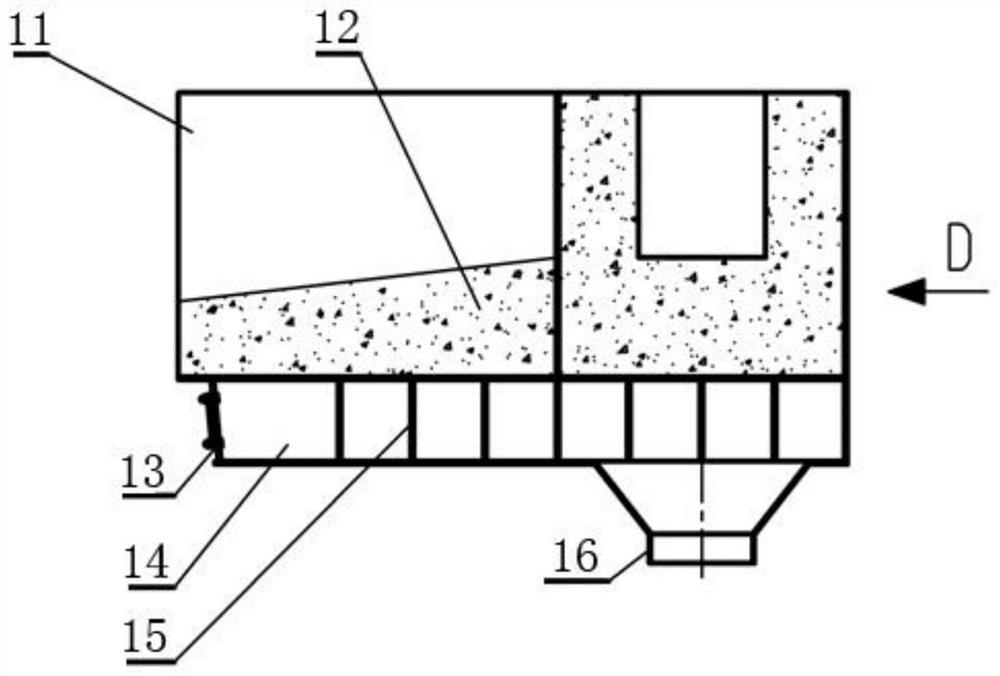

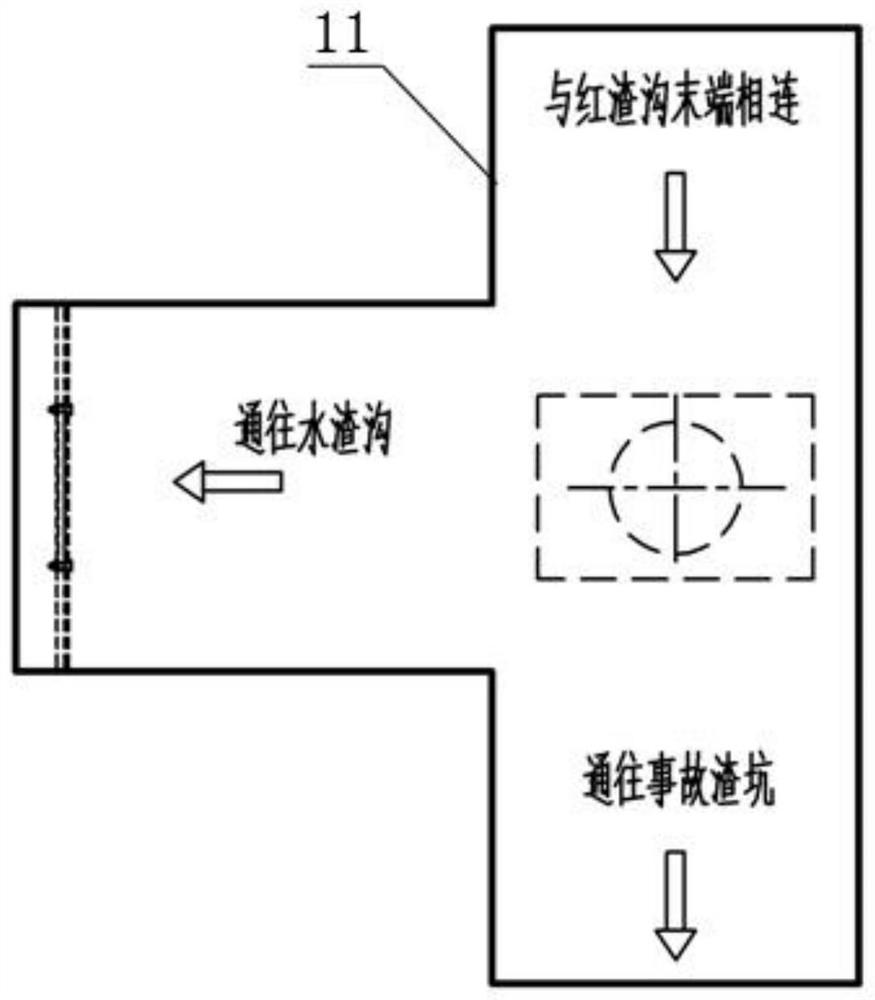

[0039] See Figure 1-Figure 15 , a blast furnace slag flushing device, including a granulatable slag ditch nozzle 1, a water slag ditch cover plate 2, and a filter pool 3. The granulizable slag ditch nozzle 1 is installed at the end of the red slag ditch. The overall hoisting of the slag ditch flow nozzle 1 is convenient and quick. The granulatable slag ditch nozzle 1 includes a steel channel 11, a water tank 14, and a porous granulation plate 13. The channel in the steel channel 11 is formed by refractory bricks or castables 12 to resist red slag erosion and heat insulation; the bottom of the steel channel 11 A water tank 14 with a cooling effect is fixed, the plane of the water tank 14 matches the bottom plane of the steel tank 11, the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com