Quantitative analysis method for volume content of each phase in QP steel

A volume content, martensite technology, applied in the analysis of materials, material analysis through optical means, material analysis using wave/particle radiation, etc., can solve the problems of insufficient contrast and difficult quantitative analysis, etc., to achieve formula Simple, promote product research and development, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Use the following steps to detect the volume content of each phase of QP steel:

[0022] (1) Preparation of colored metallographic etchant: mix 50mL water and 50mL ethanol, add 3mL concentrated hydrochloric acid, and finally add 5g sodium metabisulfite powder into the mixture, then stir rapidly with a glass rod to completely dissolve the sodium metabisulfite powder, and then add Stand in the fume hood for 2-5min;

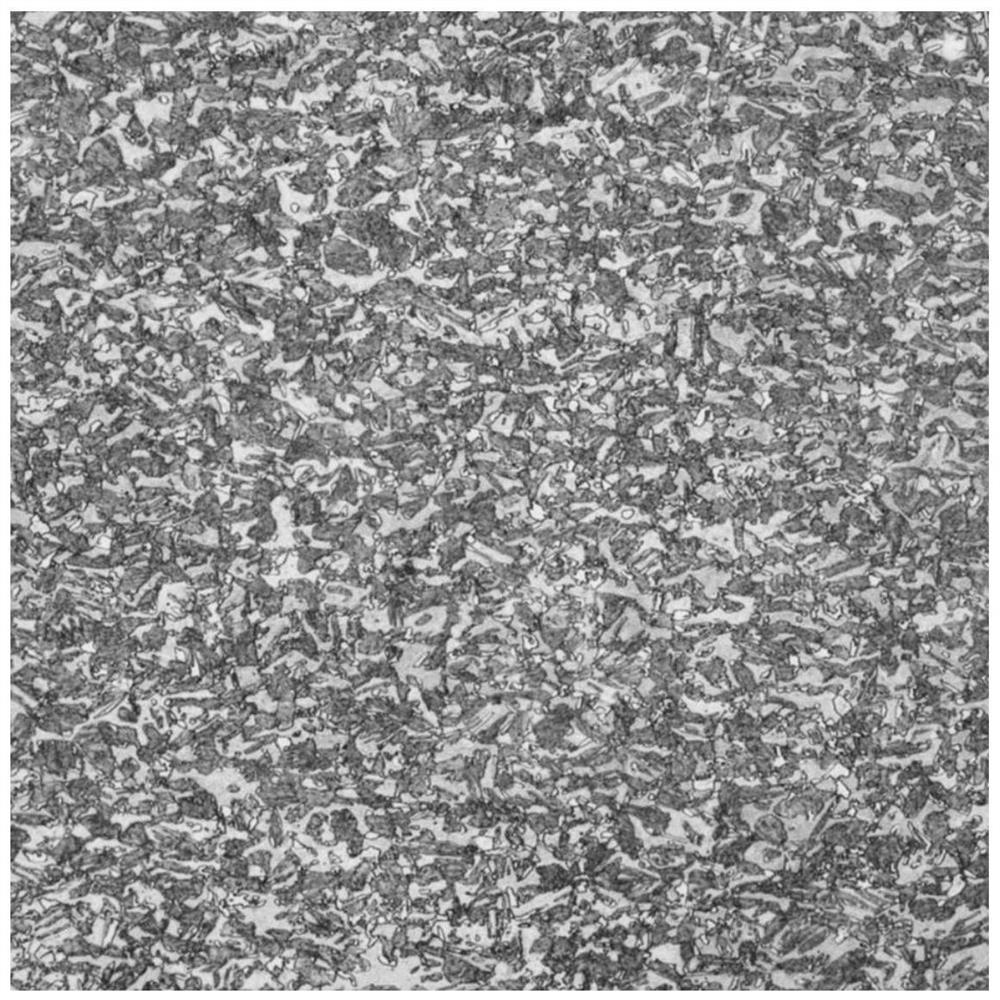

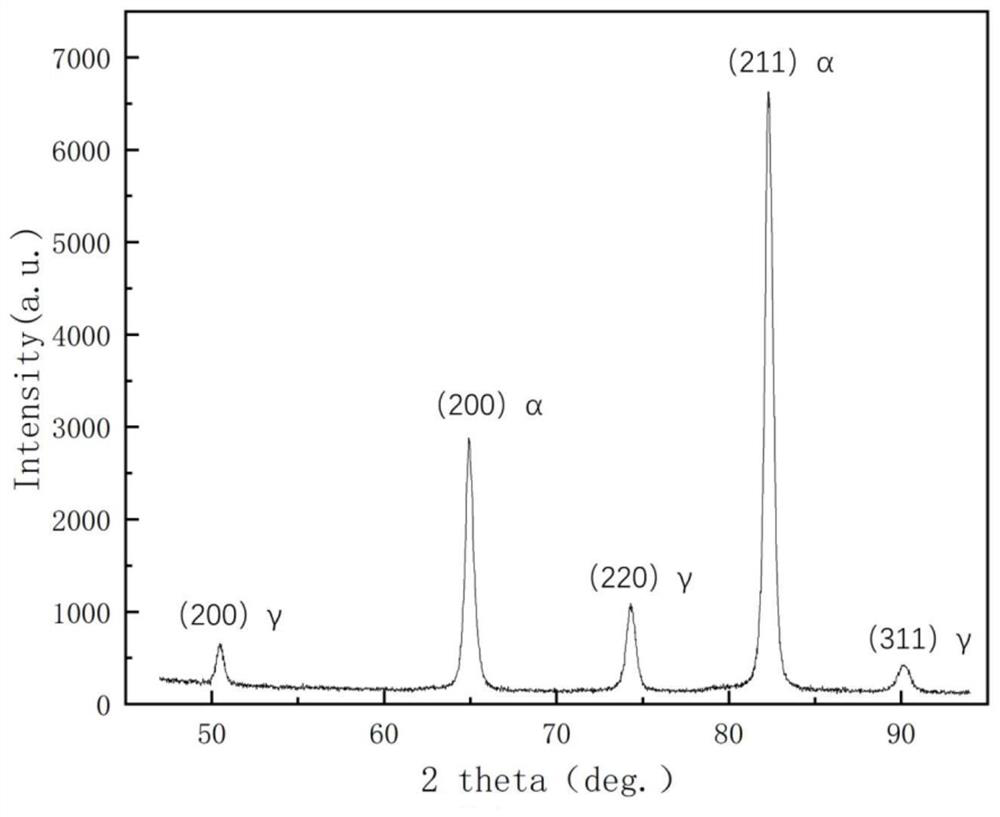

[0023] (2) Sample pretreatment: select QP980 steel produced in large industries (martensite volume content is about 60%, ferrite volume content is about 30%, and retained austenite volume content is about 10%) as the research object, and the QP Cut the steel into pieces and cold mount, then grind and polish; use the color metallographic etchant prepared in step (1) to corrode the sample for 10-30 seconds, observe while corroding, when the surface of the sample changes from bright to dark, Then rinse the surface of the sample with plenty of water, and wipe it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com