Trigger type safety protection system based on industrial electric furnace

A technology of safety protection and electric furnace, applied in the general control system, control/regulation system, program control, etc., can solve the problems of large load, no alarm system, easy damage, etc., and achieve the effect of increasing production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

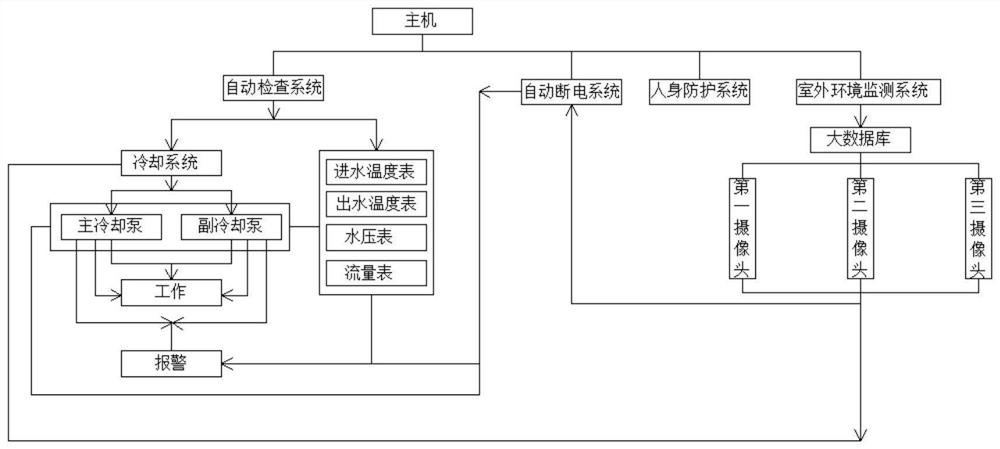

[0035] The work steps of the host, automatic check system, automatic power-off system, personal protective system and outdoor environment monitoring system are as follows:

[0036] S1: First, the outdoor environmental monitoring system is started, in the first camera, the second camera is transmitted to the large database to the large database under the action of the third camera, and if the illegal item is performed, it is timely handled, if the detection is normal Perform a next step, if alarm signal is generated during the work, you should quickly clean the prohibited items;

[0037] The outdoor environment monitoring system is set, you can view the items around the electric furnace and compare the data in large databases, which can find prohibited items to avoid dangerous context;

[0038] S2: First, the system automatically checks the system with the AD converter to control the PLC controller under the control of the single-chip microcomputer. The flow table shows normal, sel...

Embodiment 2

[0046] The first camera, the second camera and the third camera are positive triangular mounting distribution, and the first camera, the second camera is connected to the third camera;

[0047] The positive triangle distribution can make the electric furnace without dead angle monitoring, can increase security, set up the display screen, can facilitate the surrounding work environment around the electric furnace;

Embodiment 3

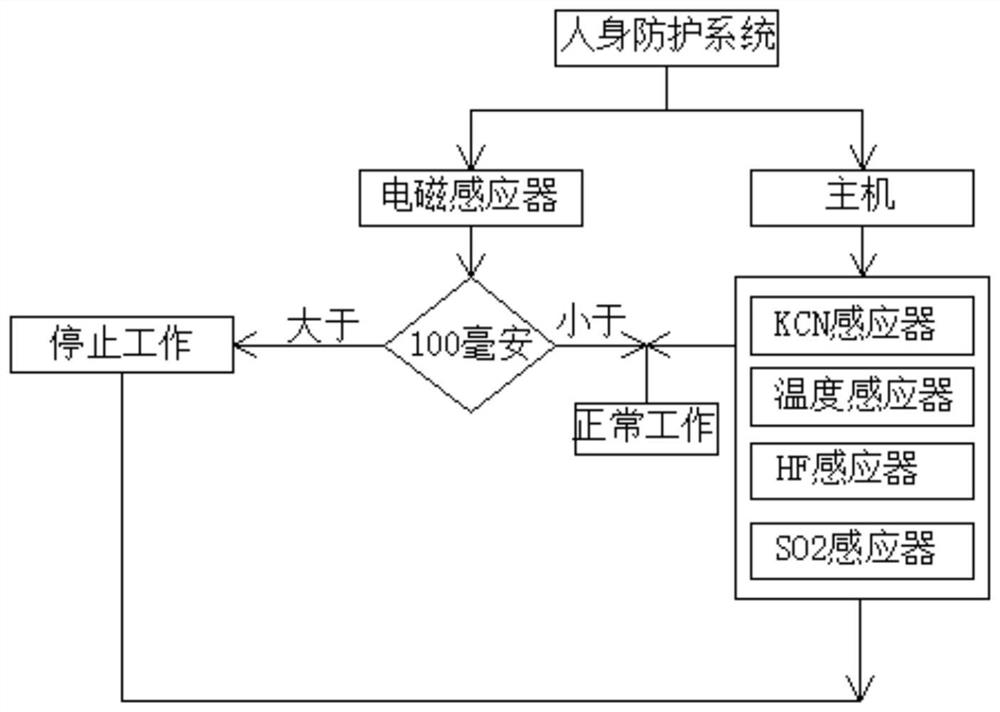

[0049] The threshold value induced by the electromagnetic inductor is 100 mA;

[0050] 100 mAh is the critical value of the human body, and if it is higher than 100 mA to generate irreversible damage to the human body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com