Prefabricated ceramic tube composite shell making process method

A process method and technology for porcelain tubes, which are applied in the field of prefabricated porcelain tube composite shell-making processes, can solve the problems of low efficiency, only a few grams to no more than ten kilograms, and incapable of large-scale casting shell-making operations, etc., and achieve process operation. Simple and convenient, shorten the production cycle and improve the efficiency of shell making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

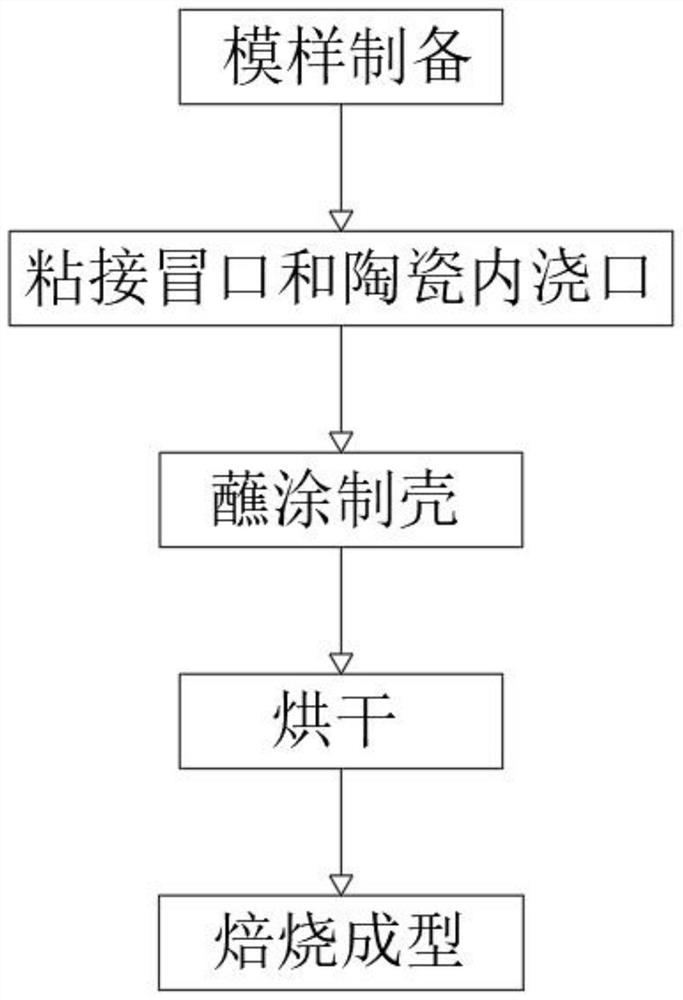

[0020] like figure 1 As shown, a prefabricated porcelain tube composite shell manufacturing process method comprises the following steps:

[0021] Step 1. Pattern preparation: The newly selected EPS material is used to make the fusible material pattern and form EPS

[0022] White mold;

[0023] Step 2. Bonding riser and ceramic ingate: Bonding and feeding on the determined position of the EPS white mold

[0024] Riser and ceramic ingate;

[0025] Step 3: Dip coating to make the shell: apply and coat several layers of refractory coating material on the outer surface of the EPS white mold;

[0026] Step 4. Drying: Place the EPS white mold that has been smeared in step 3 in the drying room for drying;

[0027] Step 5. Roasting and molding: Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com