Laser melting deposition connection method for dissimilar high-temperature alloy in aero-engine

A laser melting deposition, aero-engine technology, applied in the direction of improving energy efficiency, process efficiency, etc., can solve problems such as difficulty in realization and cracking, and achieve the effects of low porosity, high utilization rate, significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

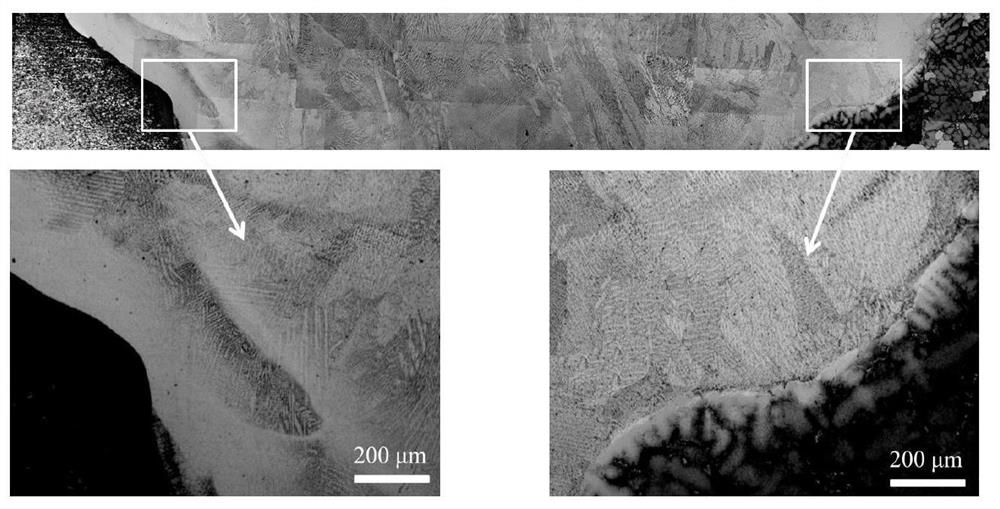

Image

Examples

Embodiment 1

[0024] The material GH4169 substrate for the wheel disc and the K417G substrate material for the blade are respectively prepared by wire cutting into trapezoids with the same size and flat surfaces. Relatively placed, fixed on the Q235 substrate by double-sided adhesive.

[0025] The GH4169 / K417G gradient material powder mixed according to the ratio of GH4169 and K417G is about 2:1 and 1:2, respectively pre-placed on the side of the GH4169 substrate and the side of the K417G substrate on the Q235 substrate, the width is greater than the two substrates and covers from the GH4169 substrate to the The entire path of the K417G substrate has a thickness of 0.3mm.

[0026] Select FL-Dlight02-3000 W type semiconductor laser, the specific process parameters are as follows: laser power P = 1600-2000W, scanning speed V = 4-6mm / s, scanning direction perpendicular to the connection between the two substrates, the path is reciprocating, The overlap rate is 40-50%. The laser scans from th...

Embodiment 2

[0028] The material GH4169 substrate for the disc and the K417G substrate for the blade are respectively prepared by wire cutting into trapezoids with the same size and flat surfaces.

[0029] Place the hypotenuses of the two substrates opposite to each other, and fix them on the Q235 substrate with double-sided adhesive. The GH4169 / K417G gradient material powder mixed at a ratio of 1:1 is pre-placed on the Q235 substrate, completely covering the path from the GH4169 substrate to the K417G substrate, and the width is larger than the two substrates, and the thickness is 0.3mm.

[0030] Select the FL-Dlight02-3000 W semiconductor laser to melt and deposit the preset gradient material powder. The specific process parameters are as follows: laser power P=1600-2000W, scanning speed V=4-6mm / s, and the scanning direction is perpendicular to the space between the two substrates. The connection path is reciprocating, the overlapping rate is 40-50%, the laser scans from the side of GH41...

Embodiment 3

[0032] The material GH4169 substrate for the disc and the K417G substrate for the blade are respectively prepared by wire cutting into trapezoids with the same size and flat surfaces.

[0033]Place the hypotenuses of the two substrates opposite to each other, and fix them on the Q235 substrate with double-sided adhesive. The GH4169 powder is pre-placed on the Q235 substrate on the side of the GH4169 substrate and the side of the K417G substrate. The width is larger than the two substrates and covers the entire path from the GH4169 substrate to the K417G substrate. The thickness is 0.3mm. Select FL-Dlight02-3000 W type semiconductor laser, the specific process parameters are as follows: laser power P = 1600-2000W, scanning speed V = 4-6mm / s, scanning direction perpendicular to the connection between the two substrates, the path is reciprocating, The overlap rate is 40-50%. The laser scans from the side of the GH4169 substrate, stops when it reaches about half the distance betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com