Welding device with cooling function for steel plate machining and using method of welding device

A welding device and steel plate technology, which is applied in the field of steel plate processed products, can solve the problems of poor practicability and low cooling effect, and achieve the effects of improving welding stability, improving purification effect, preventing shaking and even solder joints falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

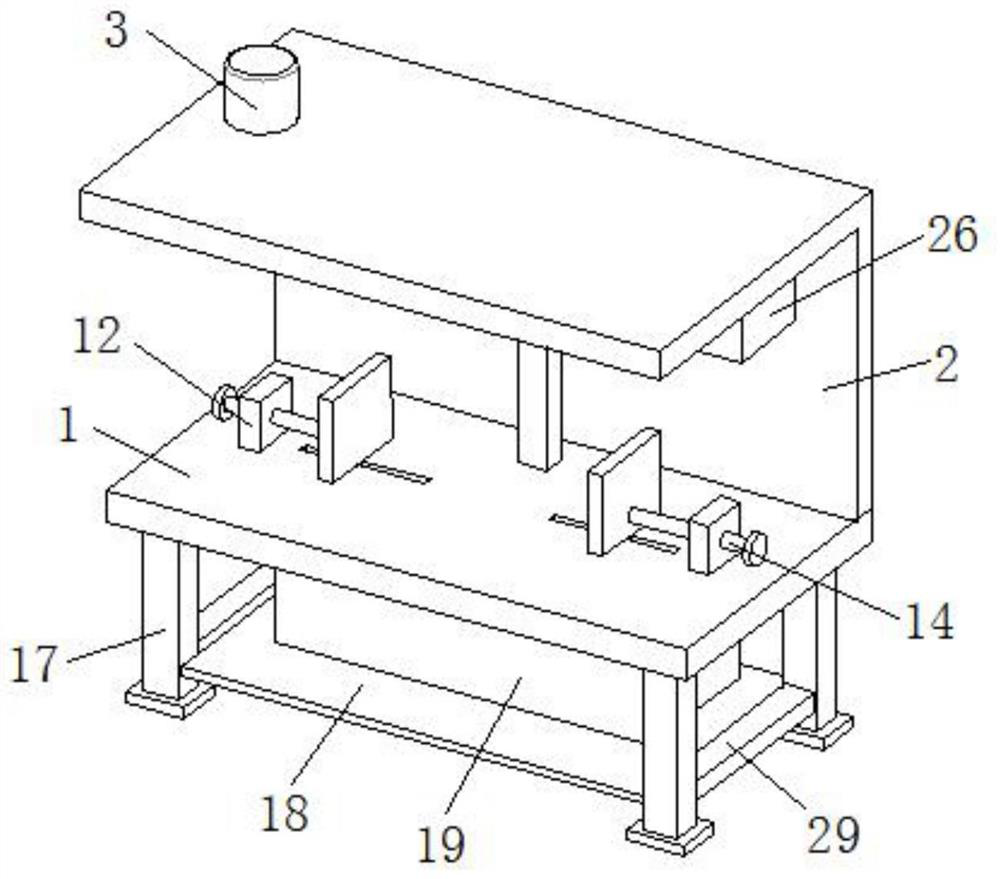

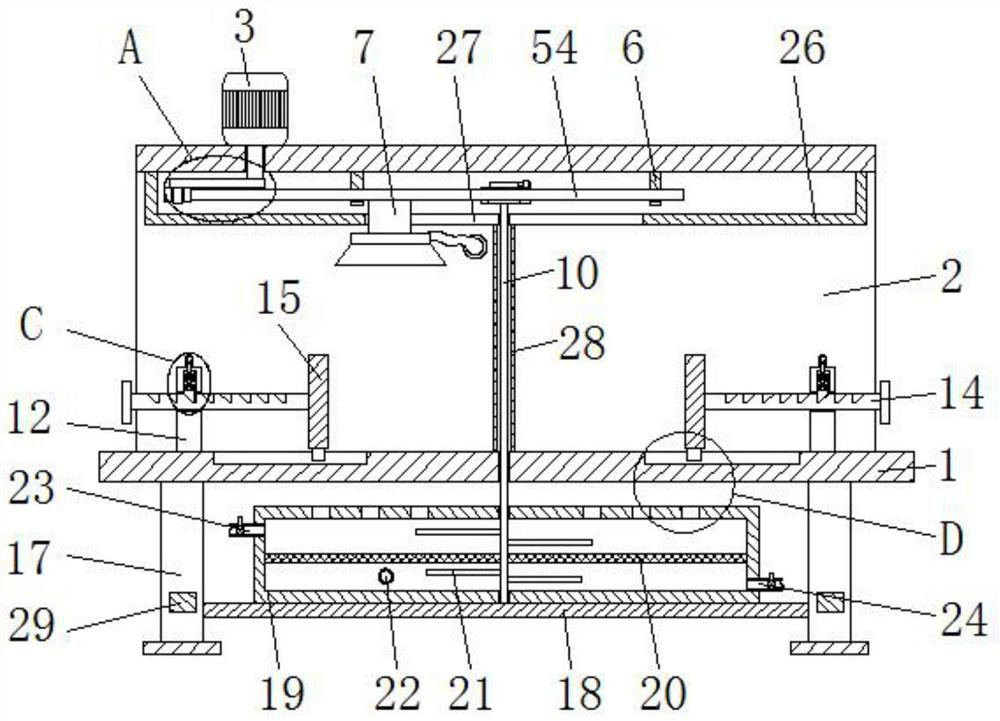

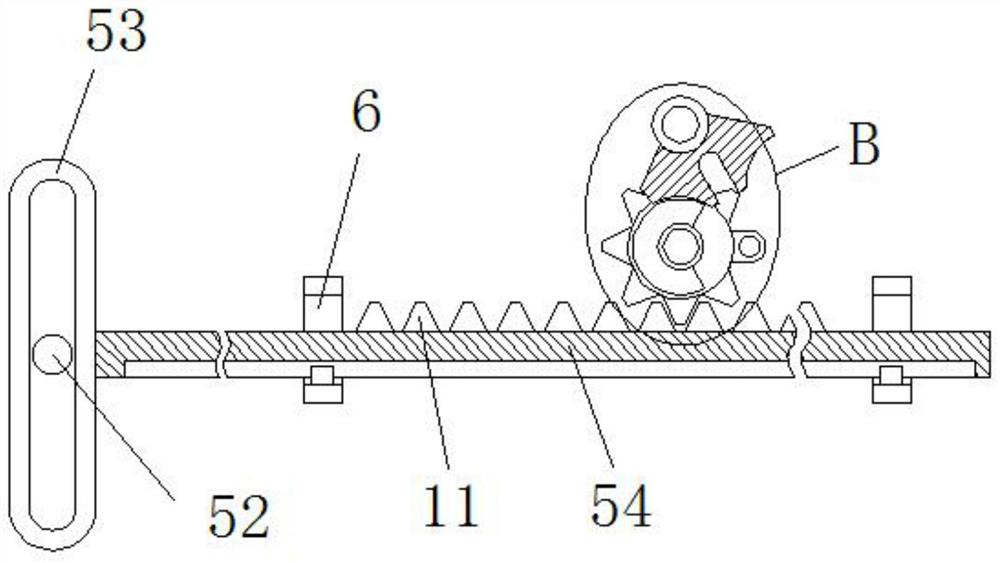

[0032] see Figure 1-7 , the present invention provides a technical solution: a welding device for steel plate processing with a cooling function, including an operation table 1, a support plate 2 is fixedly connected to the top surface of the operation table 1 near the rear side, and the support plate 2 is arranged in an L shape. A motor 3 is fixedly connected to the top surface of the support plate 2 near the left side, and a rotating shaft 4 is fixedly connected to the output shaft of the motor 3. The bottom end of the rotating shaft 4 runs through the support plate 2 and is movably connected with it. A smoker 7 is arranged below the board 2, a hose 22 is fixedly connected to the side wall of the smoker 7, a transmission mechanism 8 is arranged below the support board 2 near the rear side, and two fixed boards are fixedly connected symmetrically on the left and right sides of the top surface of the console 1 12. Through holes 13 are provided on the side walls of the fixed p...

Embodiment 2

[0036] see Figure 1-7 , the present invention provides a technical solution: a welding device for steel plate processing with a cooling function, including an operation table 1, a support plate 2 is fixedly connected to the top surface of the operation table 1 near the rear side, and the support plate 2 is arranged in an L shape. A motor 3 is fixedly connected to the top surface of the support plate 2 near the left side, and a rotating shaft 4 is fixedly connected to the output shaft of the motor 3. The bottom end of the rotating shaft 4 runs through the support plate 2 and is movably connected with it. A smoker 7 is arranged below the board 2, a hose 22 is fixedly connected to the side wall of the smoker 7, a transmission mechanism 8 is arranged below the support board 2 near the rear side, and two fixed boards are fixedly connected symmetrically on the left and right sides of the top surface of the console 1 12. Through holes 13 are provided on the side walls of the fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com