Water-soluble chemical fertilizer anti-caking agent as well as preparation method and use method thereof

A water-soluble, anti-caking agent technology, applied in the direction of application, fertilization equipment, fertilizer mixture, etc., can solve the problem of less anti-caking agent, achieve the effect of reducing surface tension, reducing interfacial tension, and excellent diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

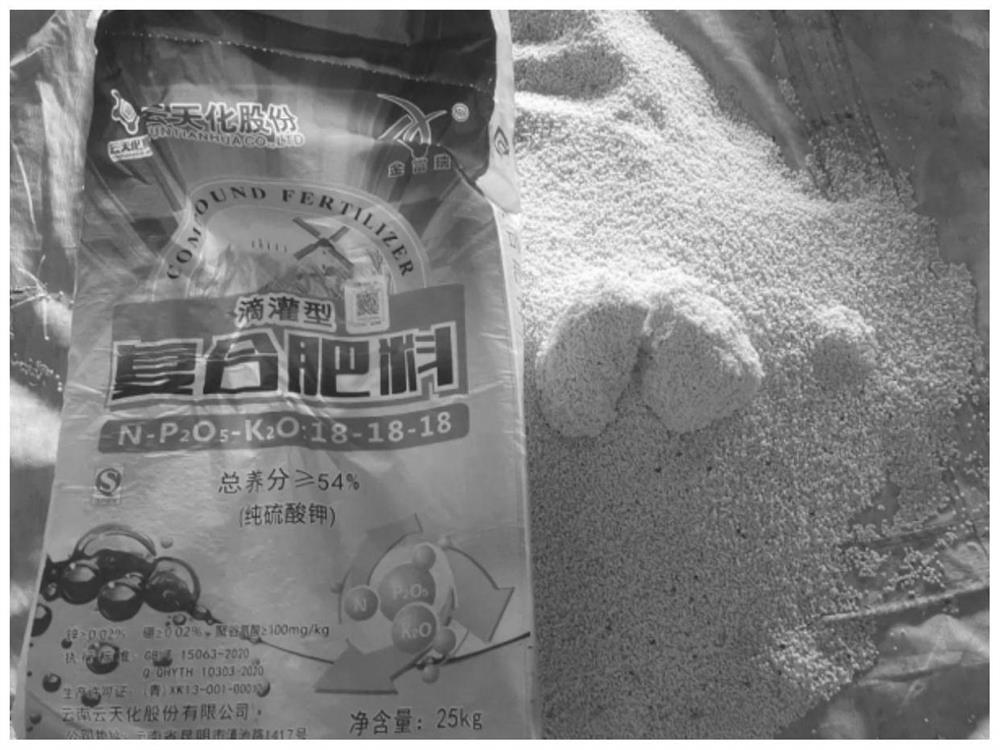

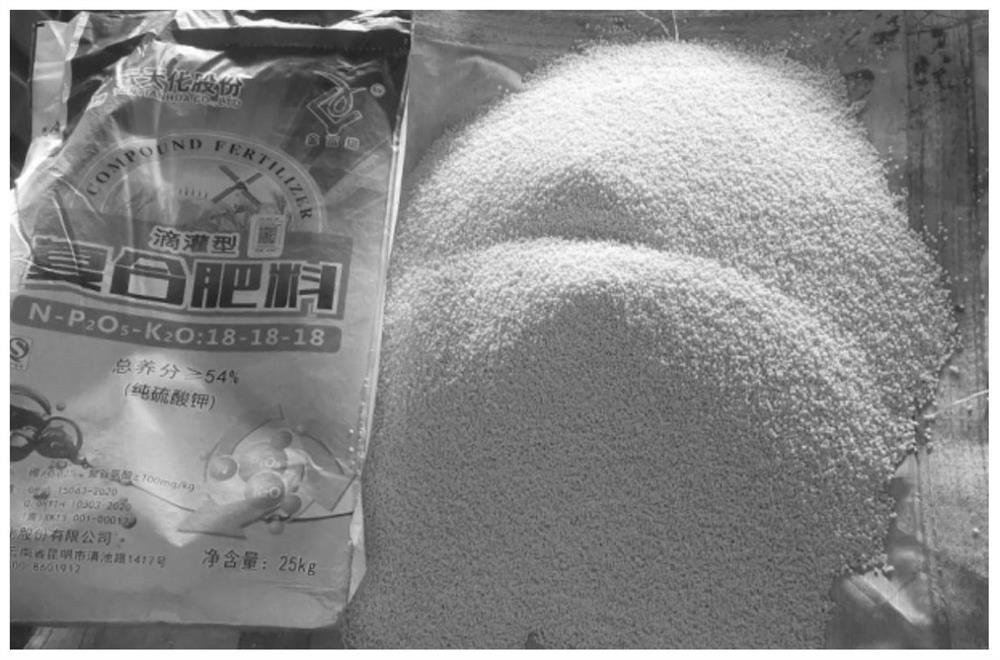

Image

Examples

Embodiment 1

[0044] A kind of preparation method 1 of water-soluble chemical fertilizer anticaking agent, the steps are as follows:

[0045] (1) Mix 8g of polyvinyl alcohol with 200g of water, heat in a water bath, heat while stirring (stirring rate is 2000r / min) and raise the temperature to 85°C in 50 minutes, keep the temperature for 10 minutes after the polyvinyl alcohol is completely dissolved, and naturally cool down to 70°C, then add 30g sodium dodecylbenzenesulfonate, 18g sodium dodecylsulfate and 0.5g defoamer AFE1430 and continue to stir (stirring speed is 1500r / min) while heating until the dodecyl Sodium benzenesulfonate and sodium lauryl sulfate are completely dissolved;

[0046] (2) After sodium dodecylbenzenesulfonate and sodium lauryl sulfate are completely dissolved in step (1), keep this temperature and add 74g of anhydrous glycerin while stirring (stirring rate is 1000r / min), and add Then continue to stir for 20min;

[0047] (3) Under the condition of 70°C, add 26g of so...

Embodiment 2

[0050] A kind of preparation method 1 of water-soluble chemical fertilizer anticaking agent, the steps are as follows:

[0051](1) Mix 5g of polyvinyl alcohol with 210g of water, heat in a water bath, heat while stirring (stirring rate is 2000r / min) and raise the constant temperature to 85°C in 60 minutes, keep warm for 10 minutes after the polyvinyl alcohol is completely dissolved, and cool down naturally to 70°C, then add 20g sodium dodecylbenzenesulfonate, 15g sodium dodecylsulfate and 0.2g defoamer AFE1430 and continue to stir (stirring speed is 1500r / min) while heating until the dodecyl Sodium phenyl sulfonate and sodium lauryl sulfate are completely dissolved;

[0052] (2) after sodium dodecylbenzenesulfonate and sodium lauryl sulfate described in step (1) dissolve completely, keep this temperature and add 75g glycerol while stirring (stirring speed is 1500r / min), glycerine Continue to stir for 20min after the addition of alcohol;

[0053] (3) Under the condition of 70...

Embodiment 3

[0094] A preparation method of a water-soluble chemical fertilizer anticaking agent, the steps are as follows:

[0095] (1) Mix 7g of polyvinyl alcohol with 180g of water, heat in a water bath, heat while stirring (stirring rate is 2000r / min) and raise the constant temperature to 85°C in 60 minutes, keep warm for 10 minutes after the polyvinyl alcohol is completely dissolved, and cool down naturally To 70°C, then add 23g sodium dodecylbenzenesulfonate, 17g sodium dodecylsulfate and 0.2g defoamer AFE0050 and continue to stir (stirring speed is 2000r / min) while heating until the dodecyl Sodium phenyl sulfonate and sodium lauryl sulfate are completely dissolved;

[0096] (2) After sodium dodecylbenzenesulfonate and sodium lauryl sulfate described in step (1) are completely dissolved, keep this temperature and add 75% of anhydrous glycerin while stirring (stirring speed is 1500r / min), anhydrous Continue to stir for 20 minutes after glycerin has been added;

[0097] (3) Add 28g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com