Microcavity optical frequency comb gas concentration sensing measurement method

A technology of gas concentration and sensing measurement, which is applied in the direction of color/spectral characteristic measurement, measuring device, neural learning method, etc. It can solve the problems of monotonous measurement methods and limited measurement of gas samples, so as to enrich the sensing dimension and improve the sensing performance. Sensitivity and noise tolerance, and the effect of improving sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In the embodiment of the present invention, a silicon substrate SiO is proposed 2 Si 3 N 4 Film to study microcavity optical frequency comb, which is shown in Table 1.

[0038] Table 1: Microcal resonance cavity parameters of microcapheric comb

[0039]

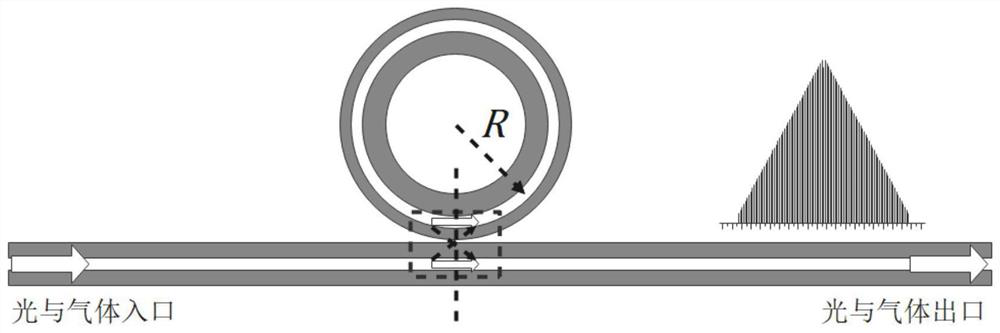

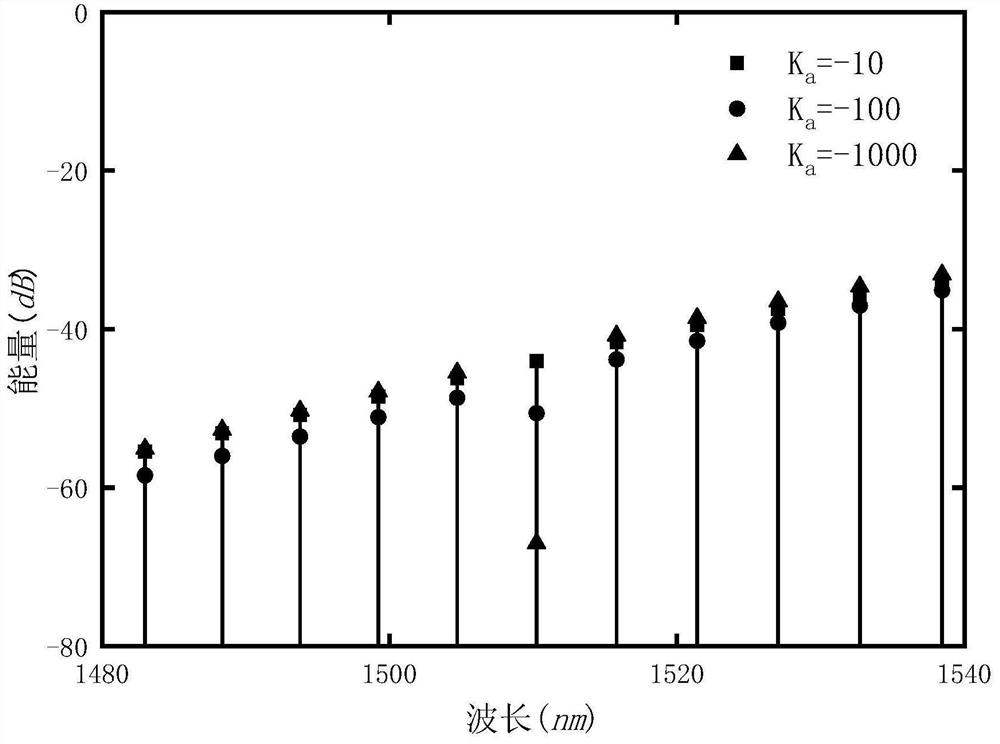

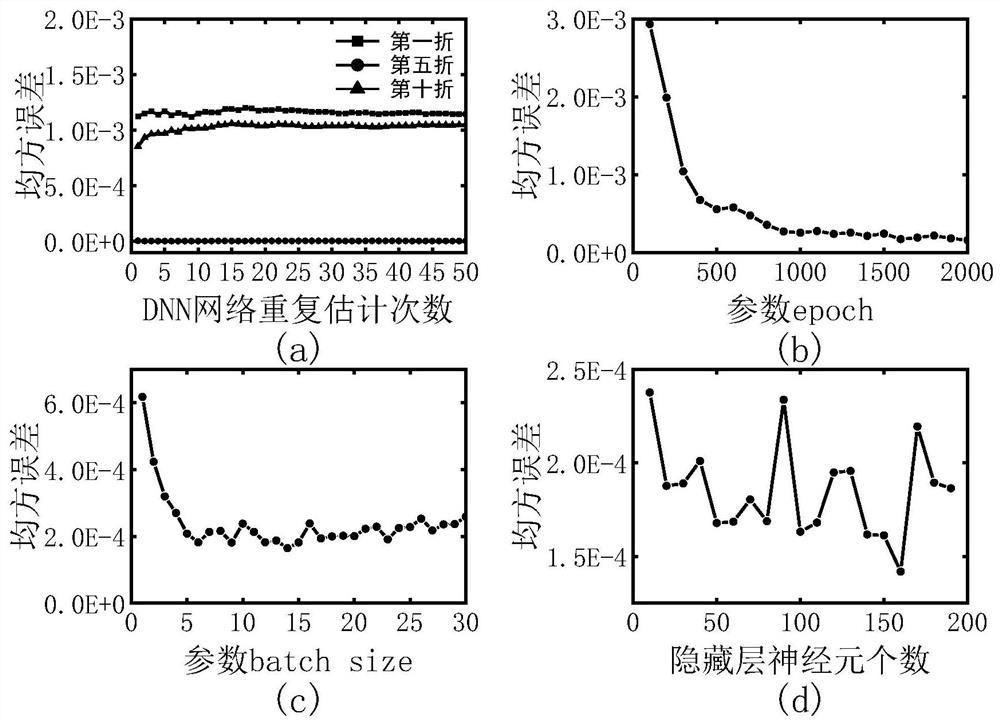

[0040] The microcarronic cavity structure of the microcomputer optical frequency comb figure 1 As shown, the response type detected sensing, the light field is limited to the resonant cavity, but some energy is still leaked into the environment by the deserted field, when the material is tested is close to the ecch of the microcavity and enters the faded field After the interaction with the deceased, the micro-ring waveguide will result in a variation of the effective refractive index, which in turn leads to dissipation rate κ for optical comb comb. α Change, causing the optical comb tooth energy value change. The optical comb variations and sensing targets are complex nonlinear mapping relationships, and the application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com