Board end connector assembly testing machine

A technology of board-side connector and testing machine, which is applied in the direction of electrical connection test, connection, and test of dielectric strength, etc., and can solve the problem of internal connection not in place, failure to use normally, failure of board-side connector assembly fit, conduction function inspection and other issues to achieve the effect of ensuring the yield rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will now be described in detail with reference to the accompanying drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

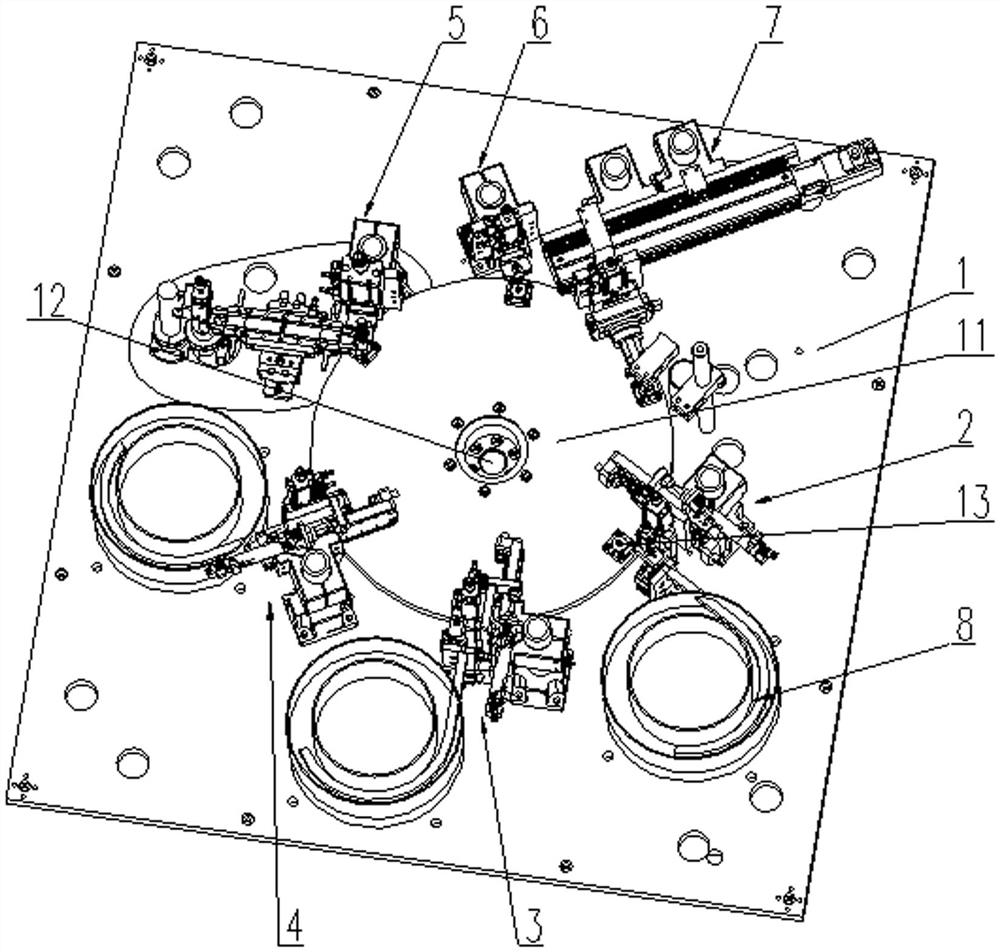

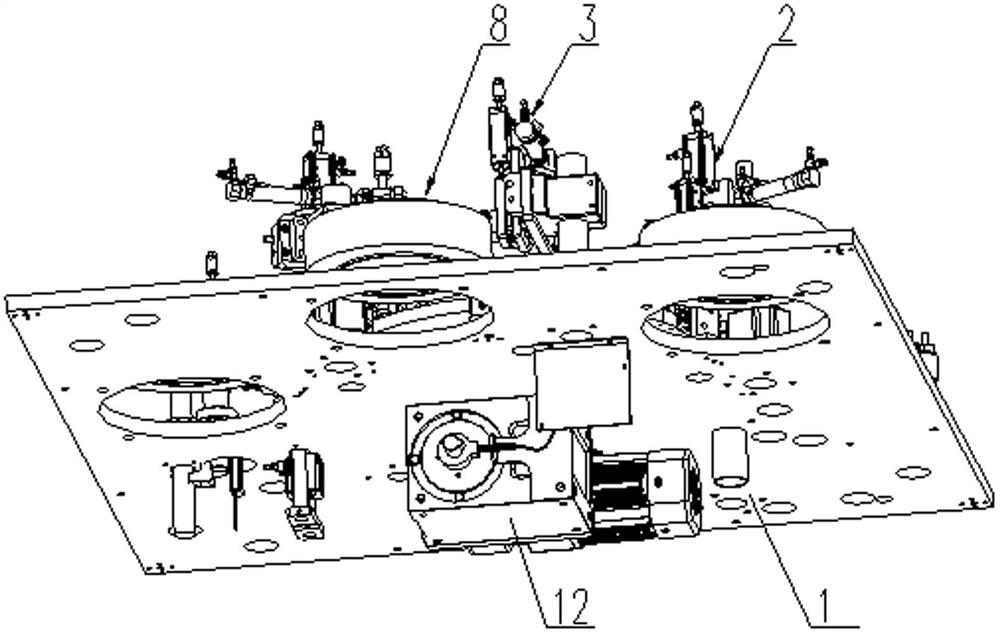

[0047] like figure 1 It is a schematic structural diagram of the present invention, a plate-end connector assembly test machine, including a base 1, rotatably mounted on the turntable 11 on the base 1, and the driving member 12 of the driving turntable 11 rotation, the output terminal of the drive member 12 and the turntable 11 Turn the connection, the driver 12 is the motor, figure 1 Middle equipment structure is installed image 3 Inside the box;

[0048] The upper casing mechanism 2, the upper insulating sheet mechanism 3, the upper pin mechanism 4, the highness test mechanism 5, the pressure test mechanism 6, and visual detection mechanism 7 are sequentially mounted along the rotating plate 11.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com