Roof greening cultivation system based on biomass utilization and preparation method thereof

A roof greening and biomass technology, applied in the field of circular forest greening facilities, can solve the problems of many construction procedures, increased building load, unfavorable mechanized construction, etc., and achieve the effects of reducing environmental pollution, reducing construction difficulty, and avoiding rapid degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

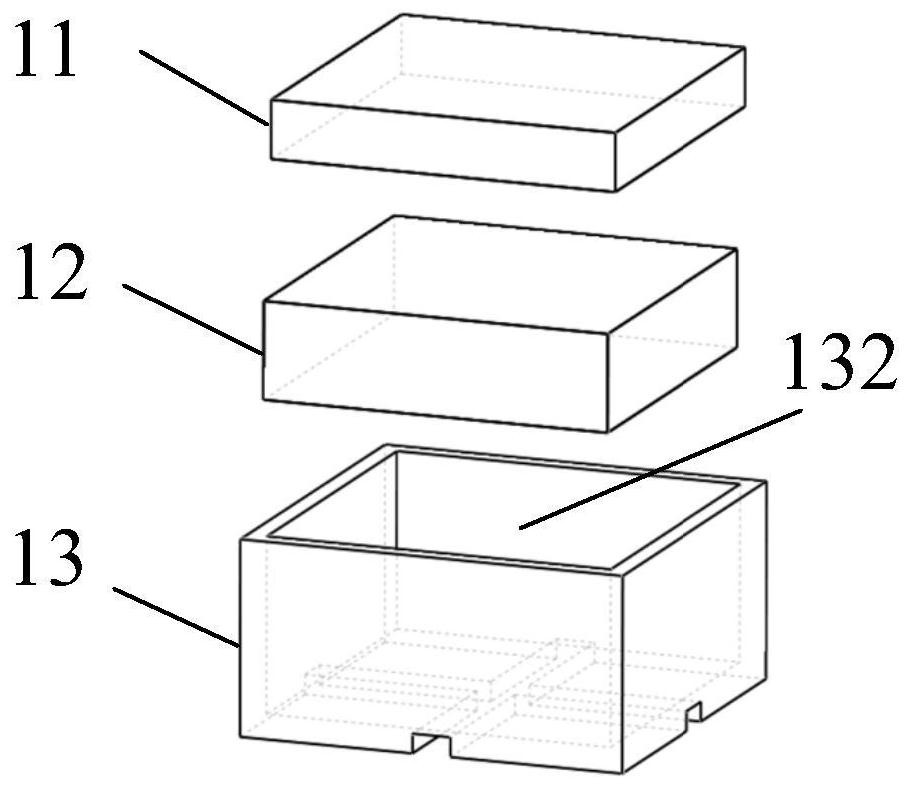

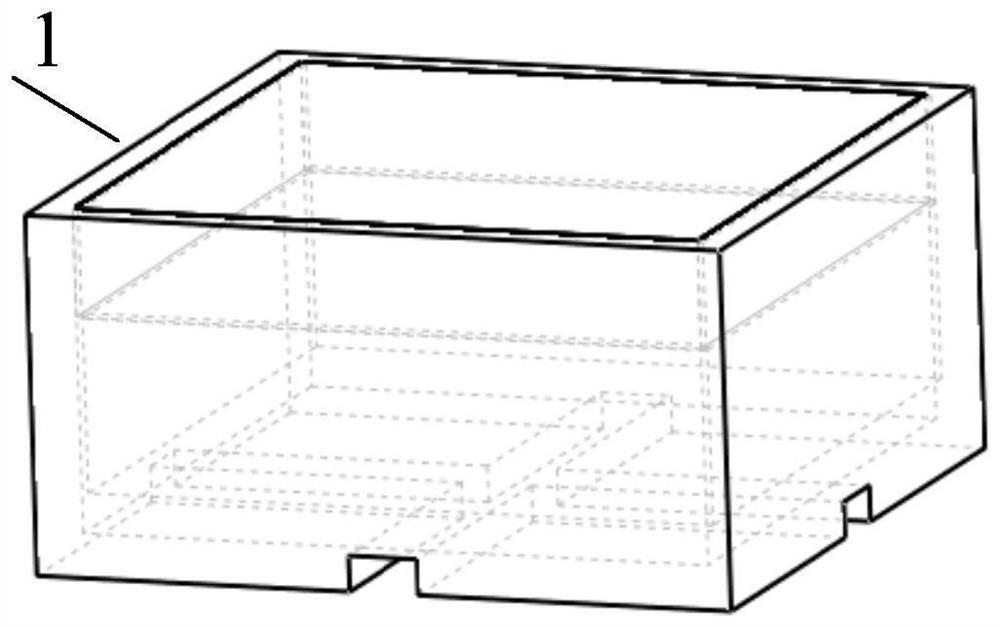

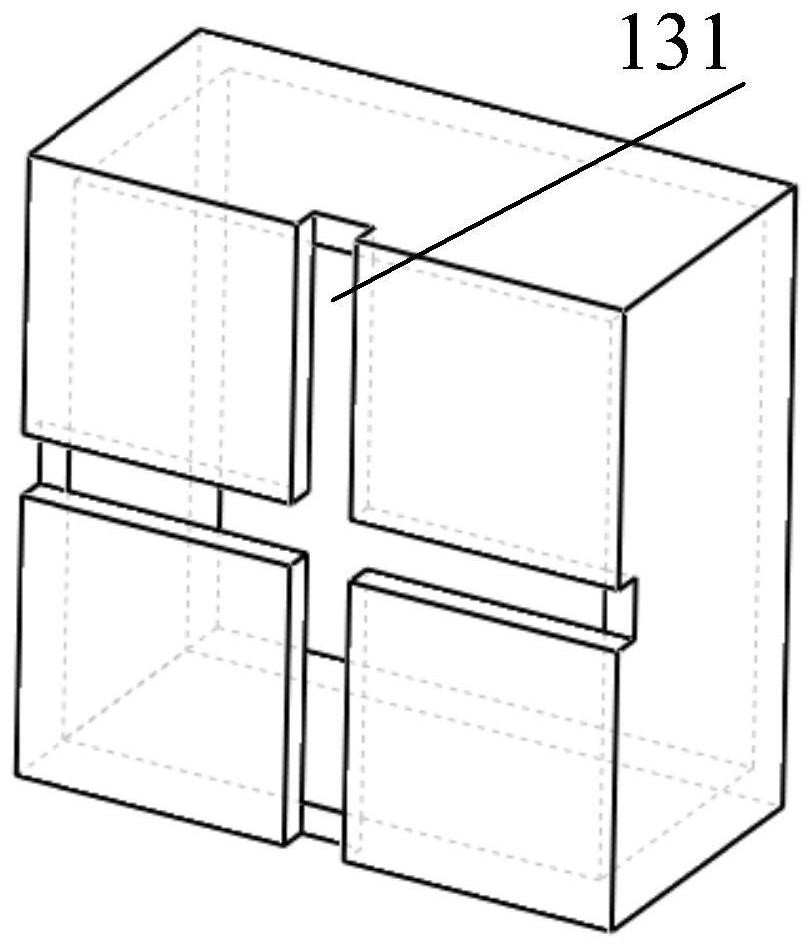

[0040] This embodiment provides a kind of roof greening cultivation system based on biomass utilization, see for details Figure 1-3 , the roof greening cultivation system 1 includes a protective shell 13, a seedling raising layer 11, and a planting layer 12, and the seedling raising layer 11 and the planting layer 12 are all arranged in the protective shell 132, and are distributed sequentially from top to bottom; The seedling layer 11 is a product obtained by retting wheat straw pretreated with an excessive concentration of 5% wood vinegar, wherein the grain size of the wheat straw is 0.5mm; the planting layer 12 is added with a concentration of 10% wood vinegar wheat straw and fresh cow dung are mixed and composted a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com