Method for improving emulsifying capacity of glyceryl monostearate emulsifying system

An emulsifying system and monoglyceride technology, applied in cosmetics, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of incomplete emulsification, unstable emulsification, and coarse emulsified particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

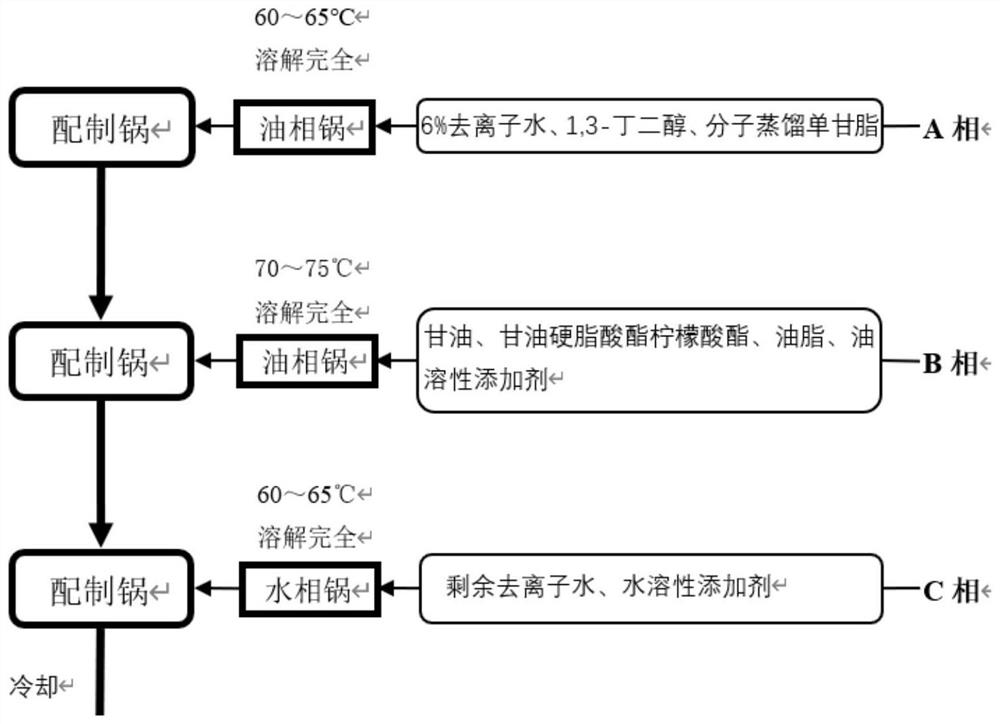

[0118] The emulsification process of this embodiment is like Figure 1A Indicated.

[0119] The preset amount of monoglyctyl ester is first added to the aqueous 1,3-butanediol, heated to 60-65 ° C, retaining stirring until a uniform monorate hydrated solution is obtained, and a seated is obtained.

[0120] The predetermined amount of glycerol, glycerol stearate citrate, squeeza, atropol phenolic acid ester is mixed, stirred to 70-75 ° C, mix uniform, and B is obtained.

[0121] The balanced water and the preset EDTA disodium were mixed, stirred to 60-65 ° C, mix uniform, and obtained C-bearing.

[0122] The phase B is slowly put into a phase in the conventional high-speed stirring, forming a milky white hydrated emulsion. The Hydration emulsion is rapidly induced, forming the final emulsion, and the emulsification is completed.

[0123] The emulsion system component is composed of the emulsion system component:

[0124]

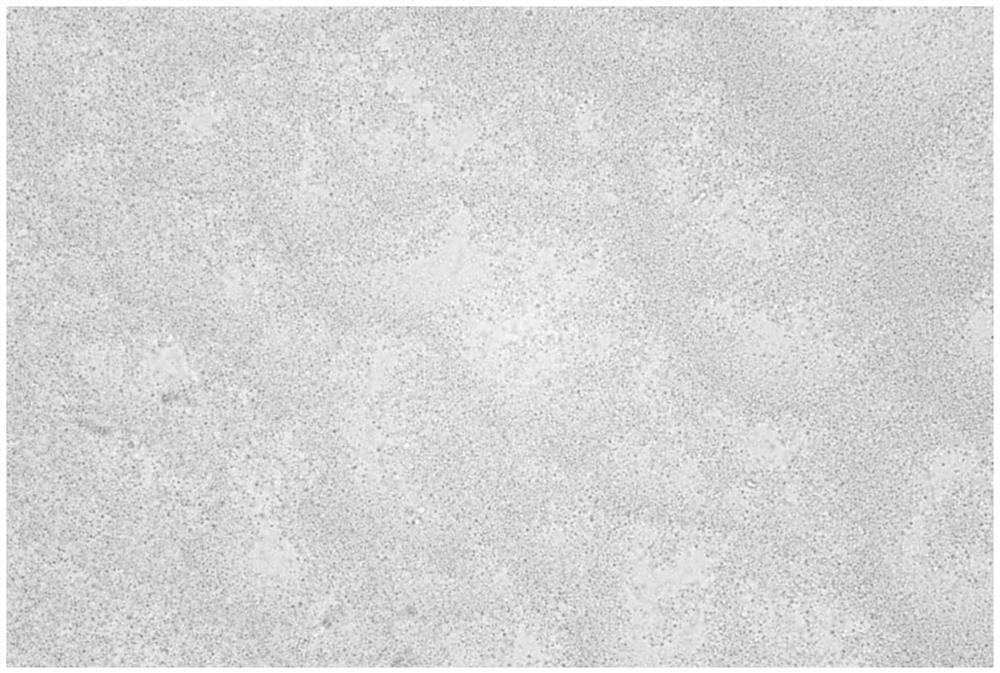

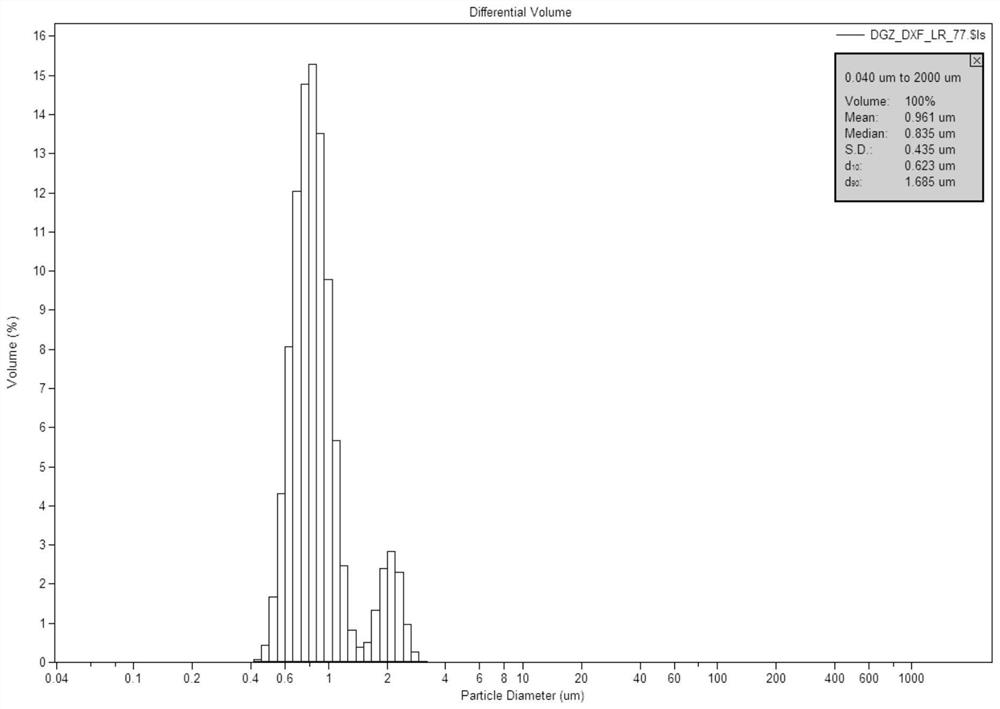

[0125] The emulsified system microscope photograph obtaine...

Embodiment 2

[0127] The emulsification process of this embodiment Figure 1A In the first, 3-butanediol aqueous solution, heated to 60-65 ° C, and the mixture was stirred until a uniform monorate hydrated solution was formed. Heat B was heated to 70-75 ° C, mix evenly, and for use. Heat C phase was stirred to 60-65 ° C, mix well, to be used. In conventional high-speed agitation conditions, the B phase slowly puts a phase A phase, forming a milky white hydrated emulsion. The Hydration emulsion is rapidly induced, forming the final emulsion, and the emulsification is completed.

[0128] The emulsion system component is composed of the emulsion system component:

[0129]

[0130]

Embodiment 3

[0132] The emulsification process of this embodiment Figure 1A In the first, 3-butanediol aqueous solution, heated to 60-65 ° C, and the mixture was stirred until a uniform monorate hydrated solution was formed. Heat B was heated to 70-75 ° C, mix evenly, and for use. Heat C phase was stirred to 60-65 ° C, mix well, to be used. In conventional high-speed agitation conditions, the B phase slowly puts a phase A phase, forming a milky white hydrated emulsion. The Hydration emulsion is rapidly induced, forming the final emulsion, and the emulsification is completed.

[0133] The emulsion system component is composed of the emulsion system component:

[0134]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com