Copper-aluminum composite plate strip as well as preparation method and device thereof

A technology of copper-aluminum composite board and copper strip, which is applied in the field of material processing, can solve the difficult problems of copper-aluminum oxidation, high gas content and slag content in aluminum board, and unstable composite strength, etc., to reduce temperature, improve quality, and roll The effect of force reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

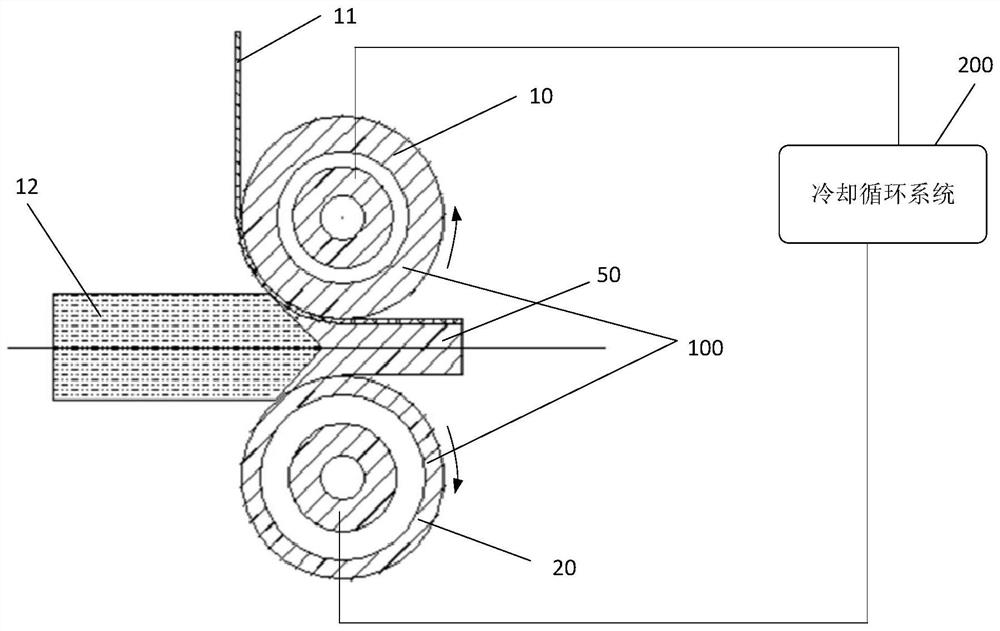

[0023] The embodiment of the present invention also provides a method for preparing a copper-aluminum composite strip, which includes: when the copper strip and molten aluminum are extruded by casting rolls to form a copper-aluminum composite strip, according to the copper layer of the copper-aluminum composite strip to be obtained Proportion Control the temperature of the upper roll and the lower roll separately; and apply a predetermined rolling force to the upper roll and the lower roll to perform compound rolling on the copper strip and molten aluminum to obtain a copper-aluminum composite strip with a predetermined composite strength .

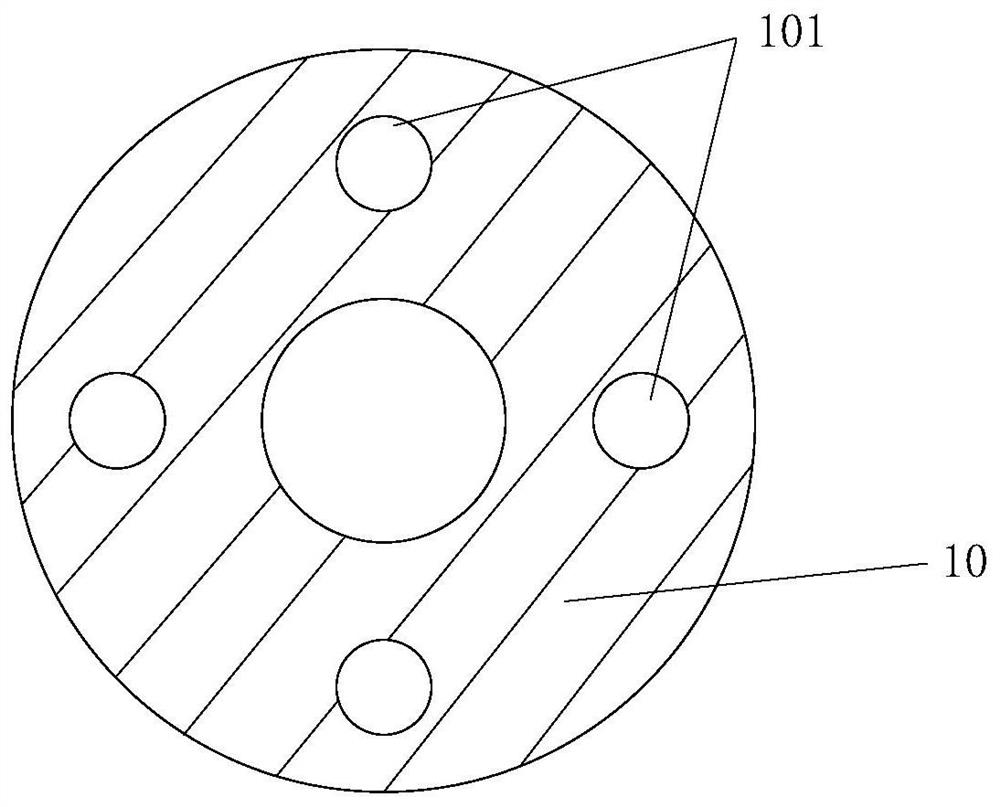

[0024] In a specific application, the temperature of the upper roll and the temperature of the lower roll are controlled separately, including: controlling the temperature of the upper roll by controlling the temperature and / or water pressure of the water flowing through the upper roll through a first regulating device connected to the upp...

example 1

[0030] Copper layer thickness: 3.0mm-4.0mm, width 600mm, composite board thickness: 6.0mm-8.0mm, copper layer ratio: 37.5%-66.0%; molten aluminum pouring temperature: 690°C-710°C, composite speed: 1000mm / min -1500mm / min, top roll water temperature: 40°C-50°C, top roll water pressure: 0.2MPa-0.3MPa; bottom roll water temperature: 20-25°C; bottom roll water pressure: 0.4-0.45MPa; rolling force 1300- 1800 tons, complete the production of copper-aluminum composite strips, the ratio of copper and aluminum reaches 50%, the composite strength is higher than or equal to 60N / mm, and the surface quality is good.

example 2

[0032] Copper layer thickness 5.0mm-5.5mm, width: 600mm; composite board thickness: 7.0mm-8.0mm, copper layer ratio 62.5%-75%; aluminum liquid pouring temperature: 700℃-720℃, composite speed: 1500mm / min- 2000mm / min, top roll water temperature: 75°C-80°C, top roll water pressure: 0.20MPa-0.25MPa, bottom roll water temperature: 25°C-30°C, bottom roll water pressure: 0.35MPa-0.4MPa; rolling force 1500 -2500 tons; composite strength greater than or equal to 50N / mm.

[0033] Based on the above-mentioned production process and equipment, the embodiment of the present invention can produce copper-aluminum composite strips with different thicknesses that meet the composite strength requirements, and can ensure product quality control. These copper-aluminum composite strips can be used as busbars and other components of battery components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com