A heat insulation partition for automobile exhaust pipe and preparation method thereof

An automobile exhaust and baffle technology, which is applied to manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of uneven thickness of automobile exhaust pipe insulation baffle, insufficient extrusion pressure control, and poor quality. and other problems to achieve the effect of optimizing the heat treatment process, improving the toughness and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1, an automobile exhaust pipe heat insulation partition, including Si: 0.2%, Fe: 0.3%, Cu: 0.1%, Mg: 0.3%, Cr: 0.4%, Zn: 0.4% by mass percentage , Ti: 0.3%, and the balance is Al.

Embodiment 2

[0059] Example 2, an automobile exhaust pipe heat insulation separator, including Si: 0.4%, Fe: 0.6%, Cu: 0.3%, Mg: 1.5%, Cr: 0.4%, Zn: 0.4% by mass percentage , Ti: 0.3%, and the balance is Al.

Embodiment 3

[0060] Example 3, an automobile exhaust pipe heat insulation partition, including Si: 0.6%, Fe: 0.8%, Cu: 0.4%, Mg: 2.5%, Cr: 0.4%, Zn: 0.4% by mass percentage , Ti: 0.3%, and the balance is Al.

[0061] Specifically, alloying elements are added to the ratio of the present invention, the content of main elements is optimized, and the heat treatment process is optimized at the same time, so that the strength and toughness of the aluminum alloy material are further improved, thereby increasing the strength, toughness and corrosion resistance of the heat insulation partition

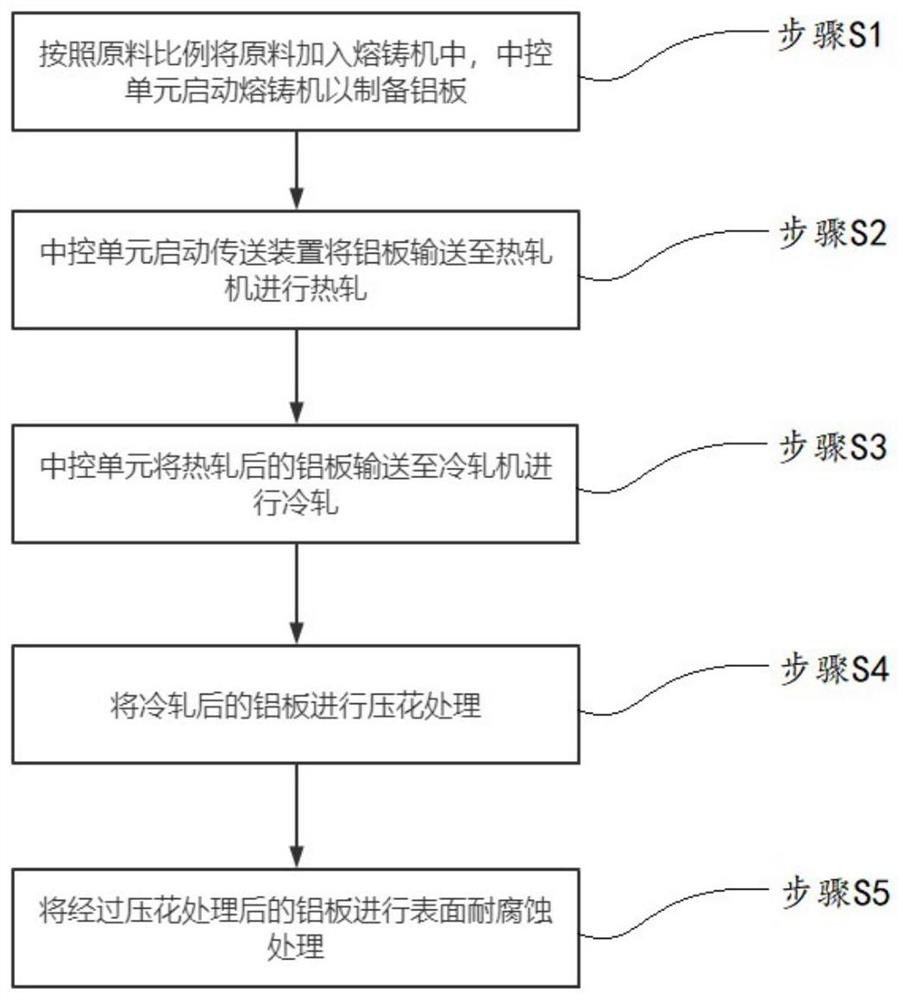

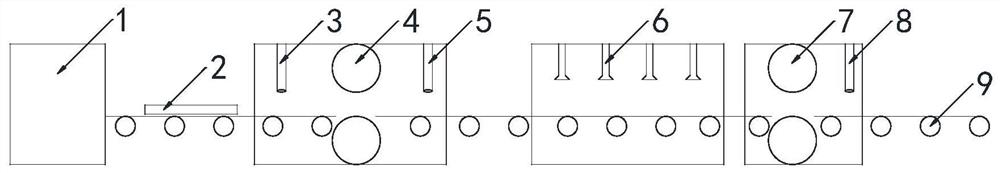

[0062] see figure 1 As shown, the schematic flow chart of the method for preparing the heat insulation partition of the automobile exhaust pipe provided by the embodiment of the present invention includes,

[0063] Step S1, adding raw materials into the melting and casting machine according to the ratio of raw materials, and the central control unit starts the melting and casting machine to prepare aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com