Machining method for machining rod head assembly for telescopic oil cylinder based on double vertical clamping

The technology of a telescopic oil cylinder and a processing method, which is applied to the fluid pressure actuating device and other directions, can solve the problems of difficult processing, complex structure, and high rejection rate, and achieve the effect of reducing the problem of processing accuracy and avoiding the difference of reference planes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

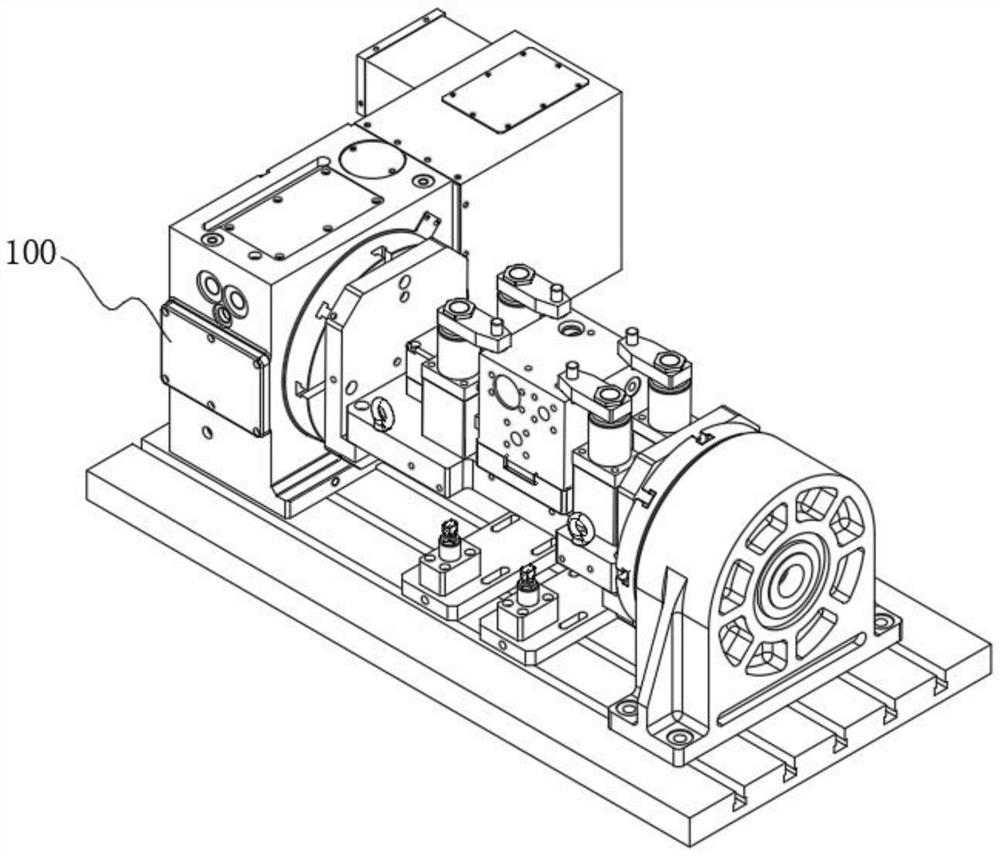

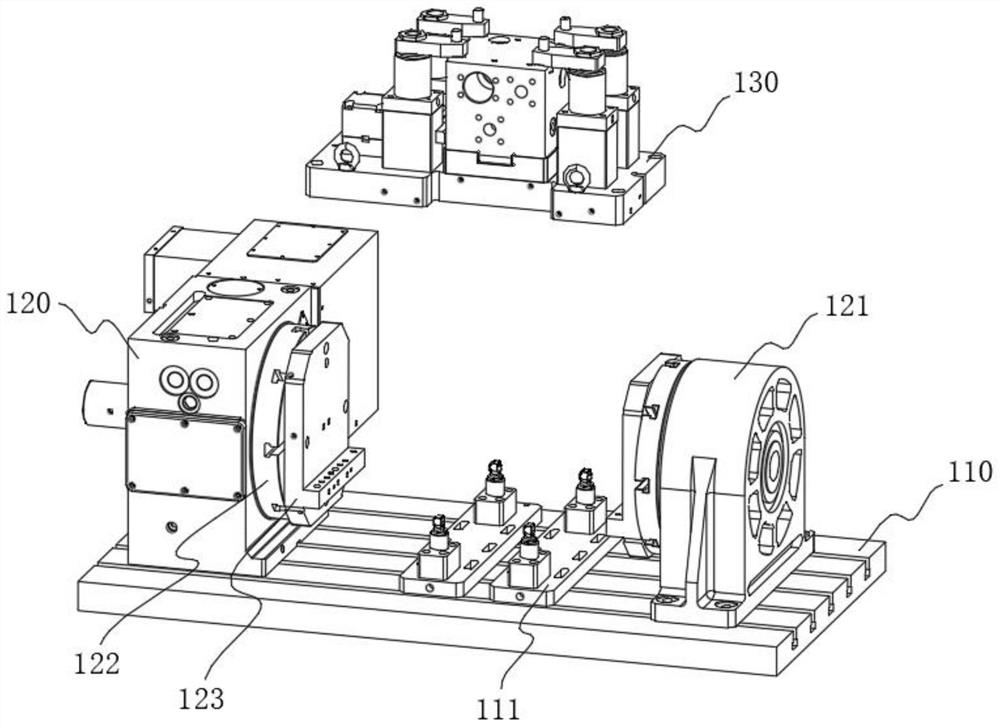

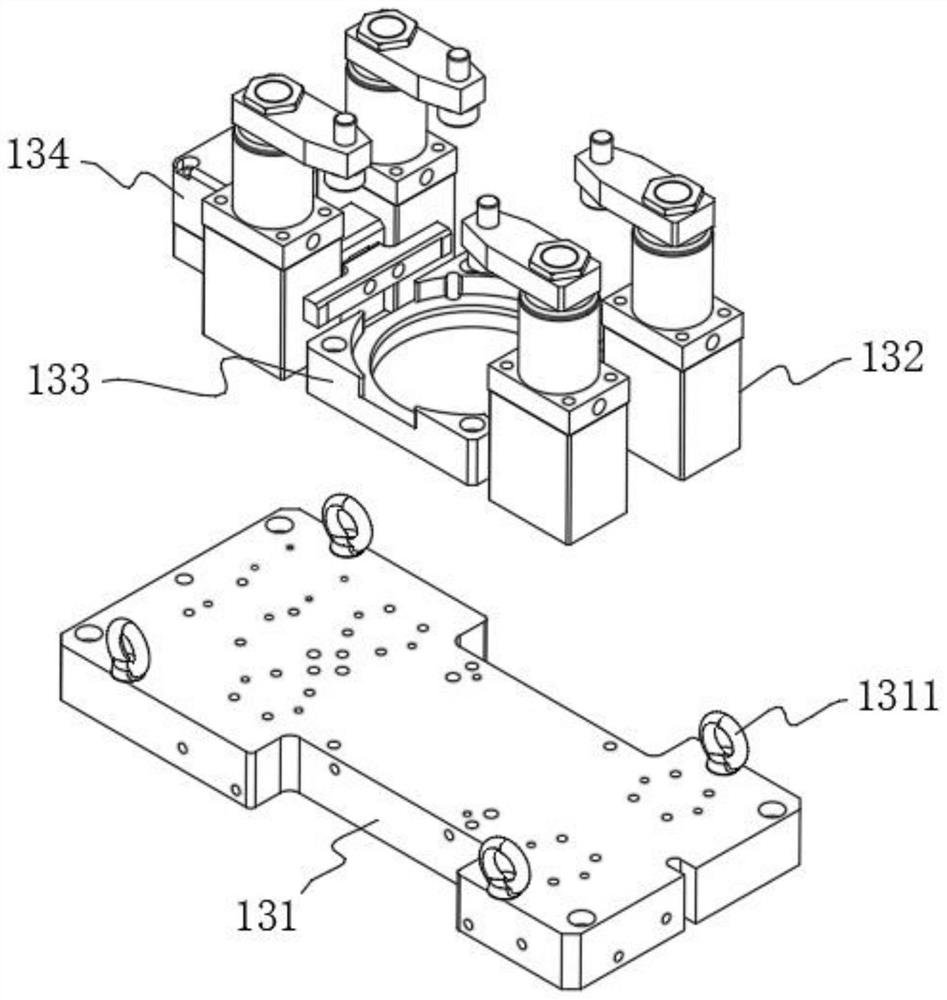

[0075] Considering that the numerical control car takes the milling end face as the benchmark, which leads to the influence of machining accuracy and the high quality risk, this embodiment discloses the multi-face vertical clamping device 100 in S5, please refer to figure 1 with figure 2 As shown, the multi-sided vertical clamping device 100 includes a workbench 110 and a positioning assembly 130 installed on the top of the workbench 110. The two sides of the positioning assembly 130 are respectively provided with a turntable 120 and a tail base 121. The turntable 120 and the tail base 121 are connected to the working The table 110 is fixedly connected, and a turntable 122 is provided on the opposite side of the turntable 120 and the tail base 121. Its main purpose is to drive the positioning assembly 130 to rotate by the drive of the turntable 120. The turntable 120 is specifically driven by four axes to realize the processing of multiple surfaces. , see image 3 As shown, ...

Embodiment 2

[0085] Since the position of the rod head workpiece cannot be guaranteed to be the optimal position after being placed, it needs to be corrected, but considering that it is not only laborious to adjust by hand, but also may cause damage to the workpiece, for this reason, this embodiment discloses a correction part 134 , see image 3 As shown, a correction piece 134 is set between two positioning pieces 132 on one side, please refer to Image 6 As shown, the correction piece 134 includes a correction cylinder 1341 and a correction plate 1343, the correction plate 1343 is fixedly connected to the telescopic end of the correction cylinder 1341, that is, the piston rod of the correction cylinder 1341, and the outside of the correction plate 1343 is slidingly connected with a guide seat 1342, which The main purpose is to support and guide the correction plate 1343, so that the position of the rod head workpiece can be corrected by using the correction plate 1343, so that the correc...

Embodiment 3

[0088] Considering that the external components of the rod head workpiece need to be welded, and the welding must be completed after drilling, but the high temperature during the welding process will cause slight deformation of the material, resulting in the inability to guarantee the processing accuracy of the valve core hole, so the multi-faceted vertical clamping equipment 100 clamping can only carry out rough boring and hook grooves on the valve core hole, and it needs to be clamped again to carry out fine boring on the valve core hole. Therefore, this embodiment discloses the single-sided vertical clamping device 200 in S10. Please refer to Figure 8 As shown, the single-sided vertical clamping device 200 includes a base 210. The base 210 is an "L"-shaped structure, thereby forming two vertical and horizontal support surfaces. The vertical support surface of the base 210 is symmetrically provided with two A stopper 220, a single-sided positioning plate 230 is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com