Rigid polyurethane foam based on low-vacuum-degree closed space as well as preparation method and application of rigid polyurethane foam

A polyurethane and rigid foam technology, applied in the field of foamed polyurethane materials, can solve the problems of increasing the foam curing time, reducing the production efficiency of the refrigerator, and poor filling of the box, so as to reduce the energy consumption of the refrigerator, reduce the range, and stabilize the thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

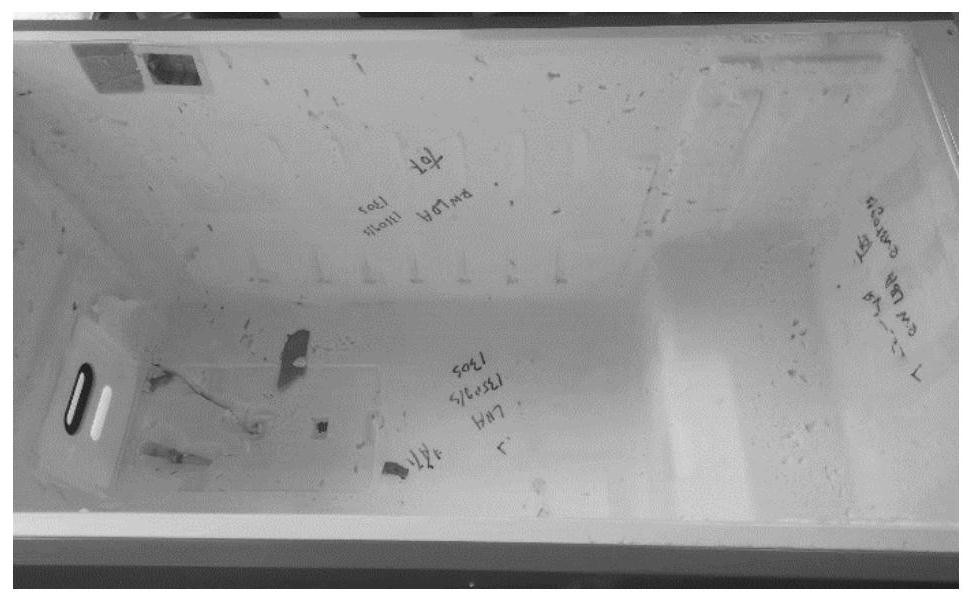

Image

Examples

Embodiment 1

[0085] Preparation of o-TDA polyether polyol:

[0086] 1) Weigh 280kg of o-TDA into the reactor, add 200kg (Boc) 2 O, heated to 50°C, stirred for 2h, cooled to normal temperature, and the surface liquid was precipitated to obtain the intermediate product A;

[0087] 2) Take all the intermediate product A, add 2200kg of propylene oxide (PO), stir at 135°C at high temperature, react for 4 hours, cool, volatilize excess propylene oxide, and obtain intermediate product B;

[0088] 3) Add 200kg of trifluoroacetic acid (TFA), control the temperature at 30°C, and fully stir for 3 hours to hydrolyze the -NBoc group to obtain the required -NH functional group, then add 200kg of dichloromethane to remove excess trifluoroacetic acid And its reaction product with -NBoc was extracted. The o-TDA polyether polyol of the present invention is obtained.

[0089] Cause (Boc) 2 The -NH groups protected by O are in different positions, and the conversion rate is not high. Therefore, the -NH grou...

Embodiment 2

[0092] Preparation of o-TDA polyether polyol:

[0093] 1) Weigh 170kg of o-TDA into the reactor, add 150kg (Boc) 2 O, heated to 60°C, stirred for 3h, cooled to normal temperature, and the surface liquid was precipitated to obtain the intermediate product A;

[0094] 2) Take all the intermediate product A, add 1000kg of propylene oxide (PO), stir at 145°C at high temperature, react for 2 hours, cool, and volatilize excess propylene oxide to obtain intermediate product B;

[0095] 3) Add 150kg of trifluoroacetic acid (TFA), control the temperature at 40°C, and fully stir for 4 hours to hydrolyze the -NBoc group to obtain the required -NH functional group, then add 150kg of dichloromethane to remove excess trifluoroacetic acid And its reaction product with -NBoc was extracted. The o-TDA polyether polyol of the present invention is obtained.

[0096] Through detection, the hydroxyl value of the synthesized o-TDA polyether polyol is 598 mgKOH / g, the viscosity is 432,799 cps, the...

Embodiment 3

[0098] Preparation of o-TDA polyether polyol:

[0099] 1) Weigh 175kg of o-TDA into the reactor, add 250kg (Boc) 2 O, heated to 40°C, stirred for 1.5h, cooled to room temperature, and the surface liquid was precipitated to obtain the intermediate product A;

[0100] 2) Take all the intermediate product A, add 1500kg of propylene oxide (PO), stir at 125°C at high temperature, react for 4 hours, cool, volatilize excess propylene oxide, and obtain intermediate product B;

[0101] 3) Add 250kg of trifluoroacetic acid (TFA), control the temperature at 20°C, and stir thoroughly for 2 hours to hydrolyze the -NBoc group to obtain the required -NH functional group, then add 250kg of dichloromethane to remove excess trifluoroacetic acid And its reaction product with -NBoc was extracted. The o-TDA polyether polyol of the present invention is obtained.

[0102] Through detection, the hydroxyl value of the synthesized o-TDA polyether polyol is 502 mgKOH / g, the viscosity is 357,356 cps, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com