Water-based aluminizing transfer coating as well as preparation method and application thereof

A transfer coating, water-based technology, used in polyester coatings, fire-retardant coatings, polycarbonate coatings, etc., can solve the problems of film transfer coatings that are not resistant to high temperature, poor aluminum plating brightness, and not resistant to hot pressing, etc., and achieve peelability. Good, the brightness can be added to the color, and the effect of temperature resistance and hot pressing can be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In some embodiments of the present invention, the preparation method of described zirconium modified water-based polycarbonate comprises the following steps:

[0038] dissolving zirconium n-propoxide and triethanolamine in ethanol, adding water to obtain a zirconium modifier;

[0039] Water-based polycarbonate is taken, the pH value is adjusted, and the zirconium modifier is added to obtain the zirconium-modified water-based polycarbonate.

[0040] In some embodiments of the present invention, the weight ratio of zirconium n-propoxide, ethanol, triethanolamine and water addition is 1:(5-20):0.5:(5-15), and the zirconium modifier addition It is 10-40% of the weight of the water-based polycarbonate.

[0041] More preferably, the preparation method of described zirconium modified water-based polycarbonate comprises the following steps:

[0042] Dissolve zirconium n-propoxide in absolute ethanol, add triethanolamine, stir ultrasonically at room temperature for 0.5h, add d...

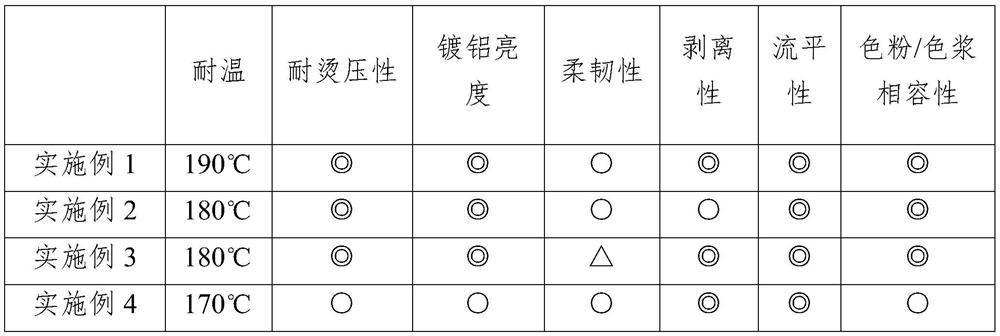

Embodiment 1

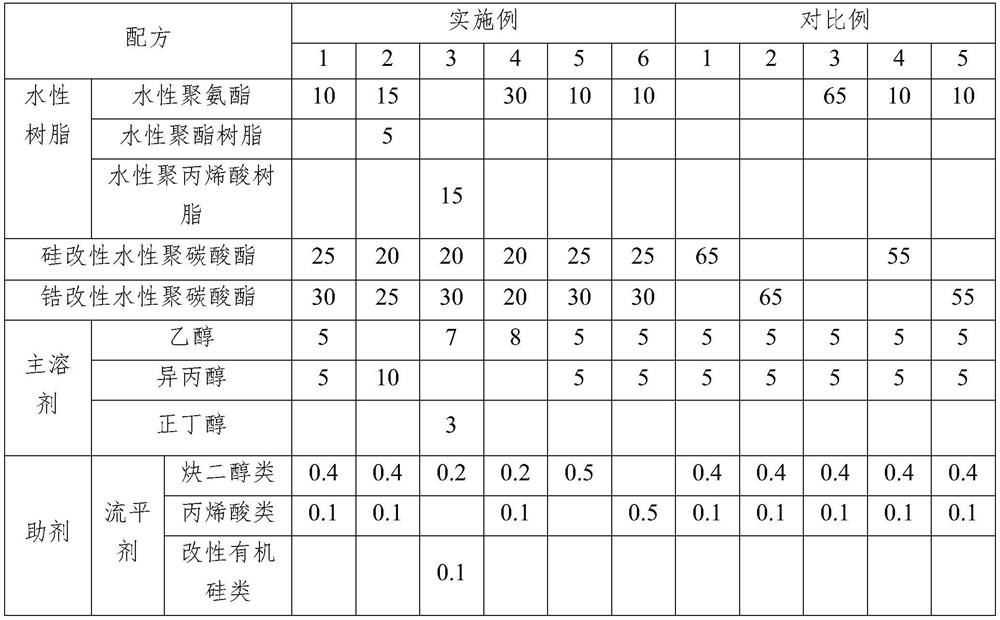

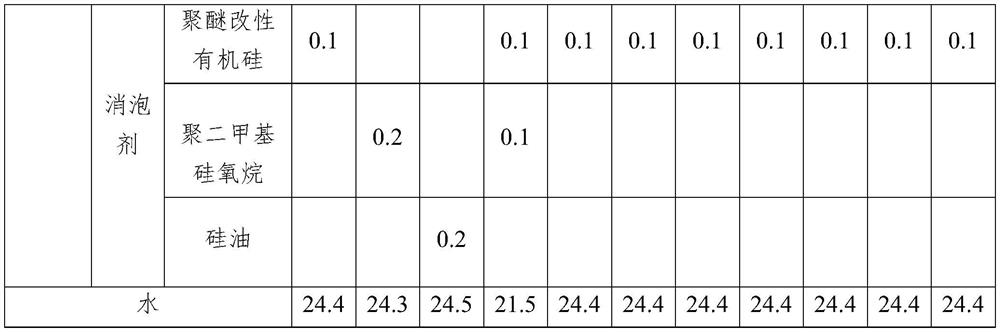

[0089] This embodiment is used to illustrate the water-based aluminum-plating transfer coating disclosed by the present invention and its preparation method, adding additives and additions according to the composition of Example 1 in Table 1, including the following steps:

[0090] Step (1): Add the additive to the main solvent at a stirring speed of 500r / min, then stir at 600r / min for 5min, add deionized water, and stir at a stirring speed of 700r / min for 10min to obtain a mixture;

[0091] Step (2): Add water-based resin, silicon-modified water-based polycarbonate and zirconium-modified water-based polycarbonate to the mixture, stir at a speed of 800r / min for 20 minutes, stop stirring, and filter through a 400-mesh filter cloth to obtain water-based aluminum plating Transfer paint.

Embodiment 2-6

[0093] Embodiment 2-6 is used to illustrate water-based aluminized transfer coating disclosed by the present invention and preparation method thereof, comprises most of the operating steps in embodiment 1, and its difference is:

[0094] The water-based resin, silicon-modified water-based polycarbonate, zirconium-modified water-based polycarbonate, main solvent, auxiliary agent and water shown in Examples 2-6 in Table 1 were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com