Efficient evaporation device for metallized film

A metallized film and evaporation technology, which is applied in vacuum evaporation plating, metal material coating process, sputtering plating, etc., can solve the problems of long time consumption and low efficiency of metallized film evaporation, and improve efficiency , meet the heating and evaporation, improve the effect of melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

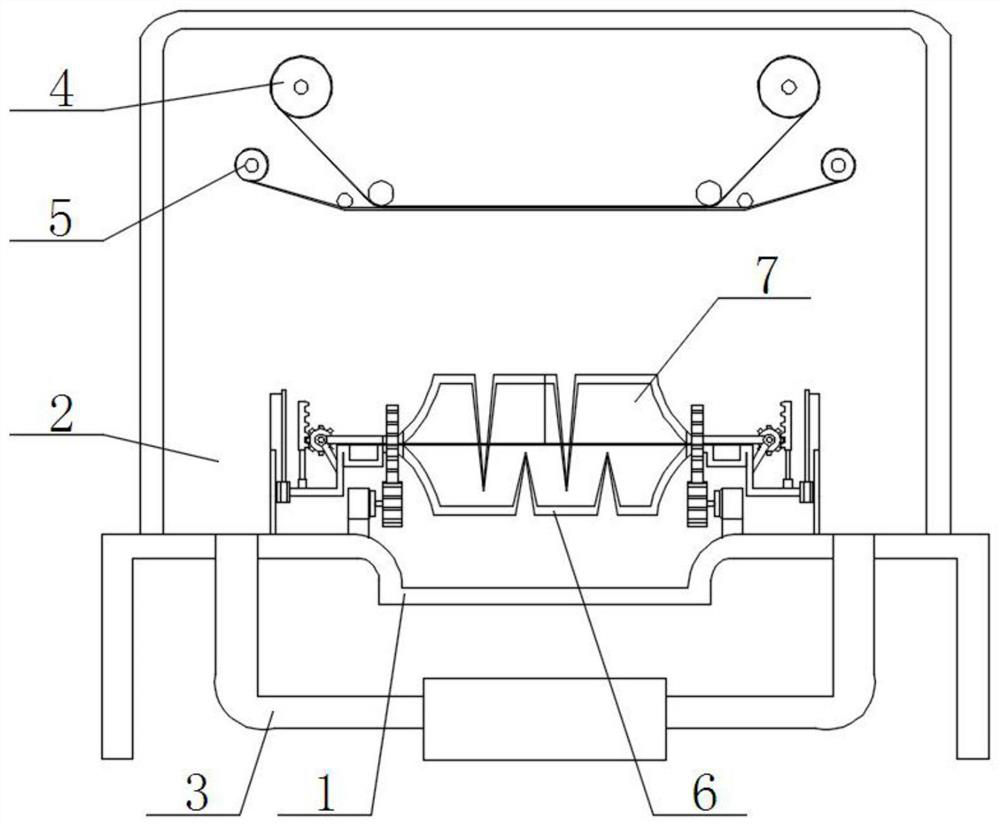

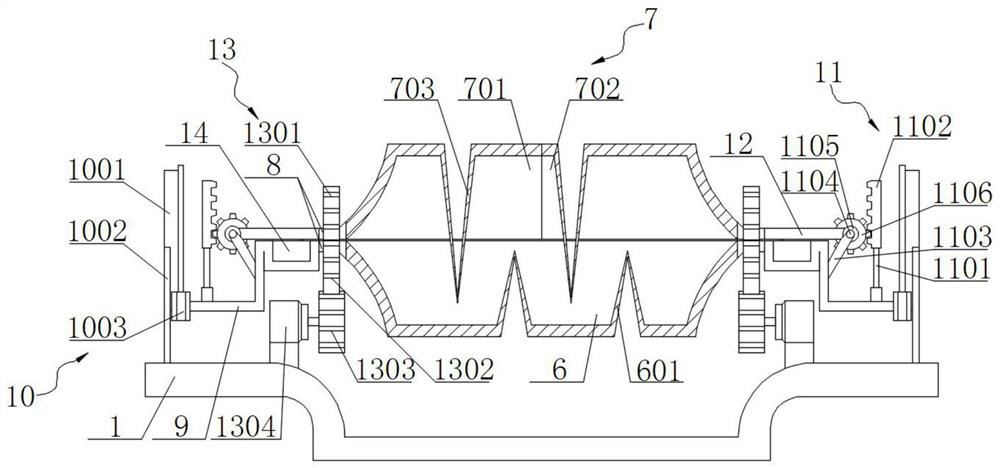

[0032] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the high-efficiency vapor deposition device of the metallized film in this embodiment includes a workbench 1, on which a vapor deposition chamber 2 is arranged, and the vapor deposition chamber 2 is externally connected to a vacuum system 3, and the interior of the vapor deposition chamber 2 is provided with a film The conveying mechanism 4 for conveying the substrate, the isolation mechanism 5 for shielding the area of the film substrate that does not need to be coated, the isolation mechanism 5 is located below the conveying mechanism 4,

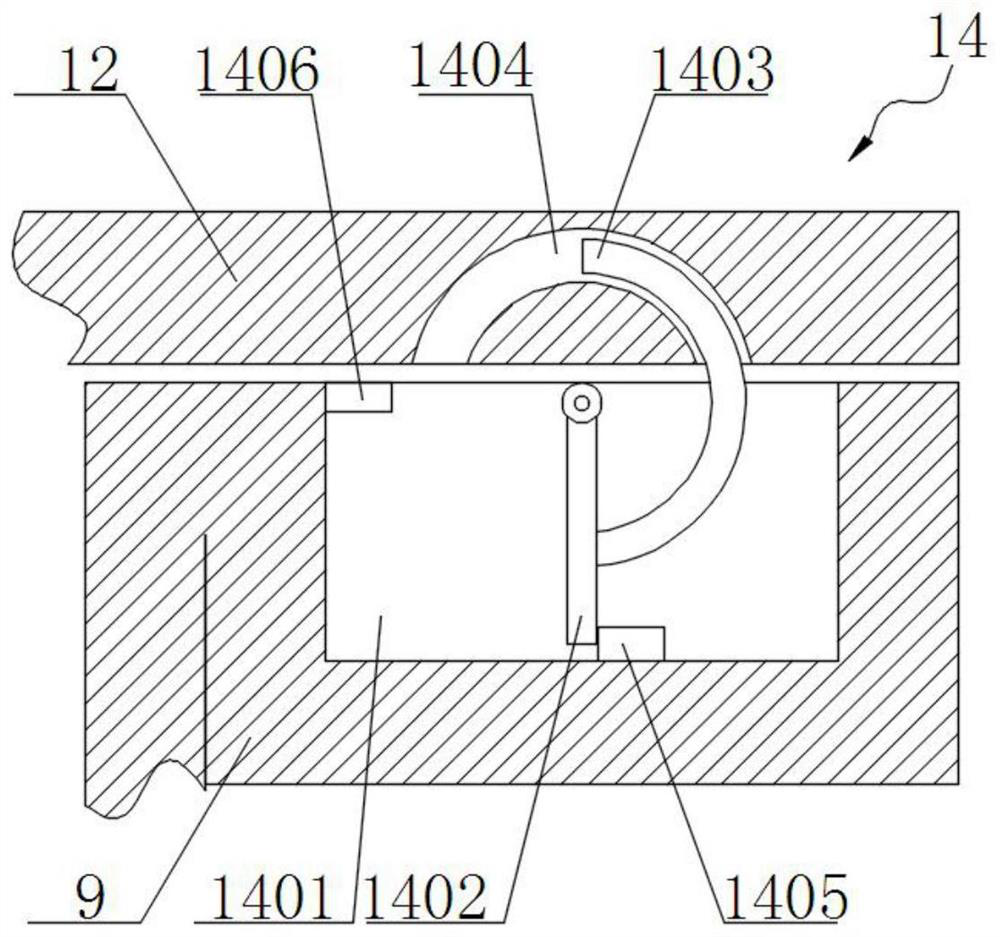

[0033] The interior of the evaporation chamber 2 is provided with a lower tungsten wire assembly 6 and an upper tungsten wire assembly 7, both ends of the lower tungsten wire assembly 6 are connected to a support substrate 9 through a socket 8, and a pair of lower tungsten wire assemblies are arranged on the support substrate 9. 6 and the support mechanism 10 supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com