Chip electronic component tin plating solution and tin electroplating method

A technology of electronic components and tin plating solution, applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve the problems of poor solderability and solder resistance, rough crystallization of tin layer, weak oxidation resistance of tin layer, etc., to achieve Good solderability and solder resistance, smooth tin layer appearance, and smooth microscopic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

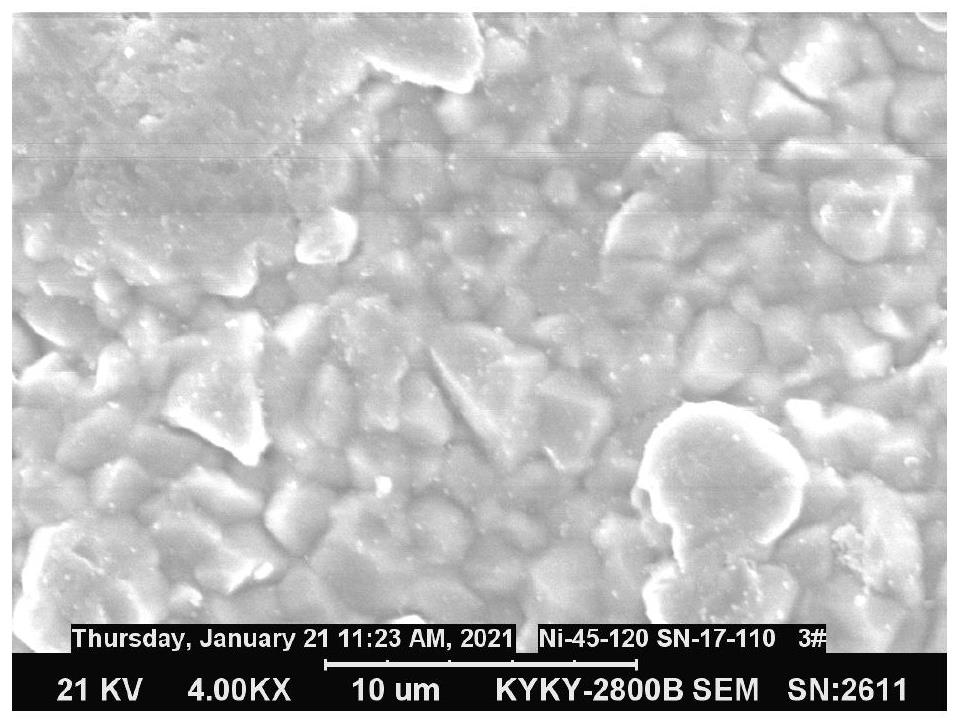

[0040] A tin-plating solution for chip electronic components uses water as a solvent, and its components and concentrations are shown in Table 1. Use this tin plating solution to perform tin electroplating on 0201 chip resistors: at a temperature of 25°C, adjust the pH value of the plating solution to 4.2, and the current density to 0.4A / dm 2 , electroplating for 100 min, to obtain an electroplated product.

Embodiment 2

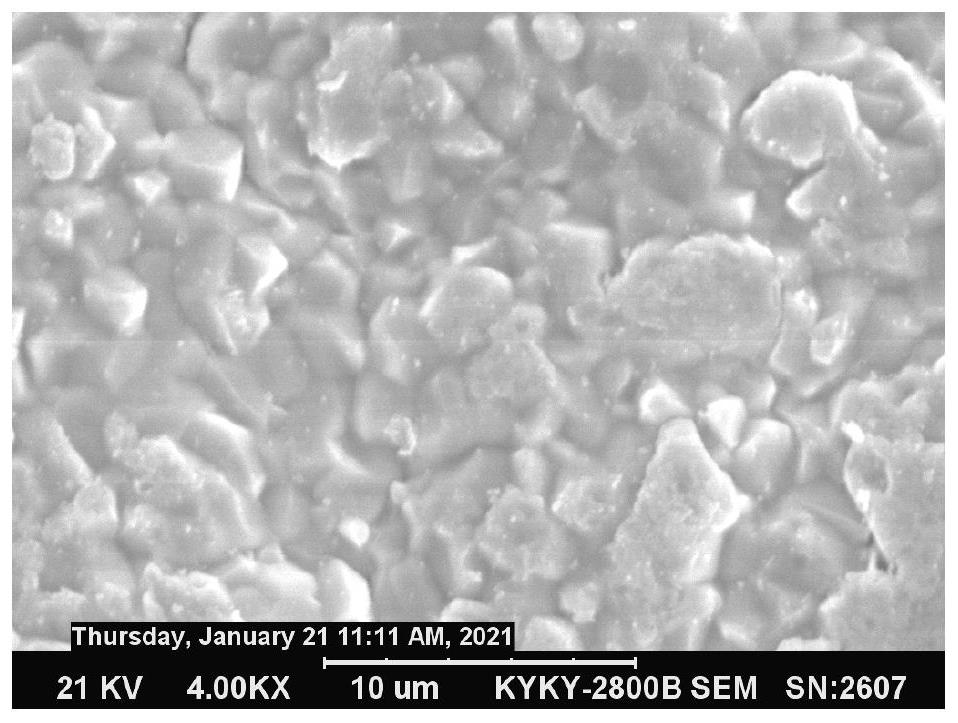

[0042] A tin-plating solution for chip electronic components uses water as a solvent, and its components and concentrations are shown in Table 1. Use this tin plating solution to perform tin electroplating on 0201 chip resistors: at a temperature of 25°C, adjust the pH value of the plating solution to 4.2, and the current density to 0.4A / dm2 , electroplating for 100 min, to obtain an electroplated product.

Embodiment 3

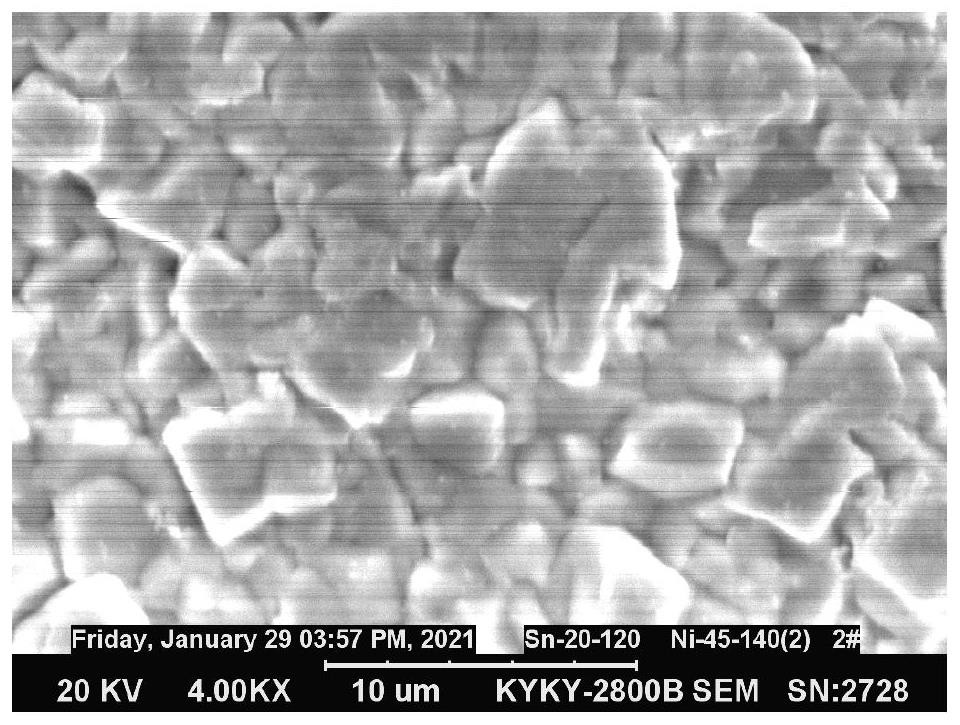

[0044] A tin-plating solution for chip electronic components uses water as a solvent, and its components and concentrations are shown in Table 1. Use this tin plating solution to perform tin electroplating on 0201 chip resistors: at a temperature of 25°C, adjust the pH value of the plating solution to 4.2, and the current density to 0.4A / dm 2 , electroplating for 100 min, to obtain an electroplated product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com